Responding to Challenges, Opportunities Of ‘Booming’ Plastics Market

Coperion sees a trend toward bigger, higher-output systems in polyolefin production, and flexibility in custom compounders.

Many look at compounding as a leading indicator for the plastics business overall. When big polyolefins companies buy multi-million-dollar lines, that’s a good sign for the industry. It means they are ramping up production, adding capacity as a result of debottlenecking, or even building an altogether new plant. When smaller custom compounders and formulators buy lines, that’s usually driven by demand from injection molding, extrusion and other processors. It starts with resin.

All that gives Coperion a unique perspective on just what’s going on in plastics. The compounding machinery supplier knows early on what the huge polyolefin suppliers are thinking thanks to its long-time, global footprint in furnishing post-reactor lines for these polymer producers. And its position supplying equipment down the materials pipeline—to compounders of engineering thermoplastics and other resins—gives it strong clues as to what’s unfolding not only among this particular group of Coperion customers, but by the converters who are buying materials from them to mold and extrude.

“In polyolefins, business is booming in the North American market,” says Ulrich Bartel, president of Coperion’s global Extrusion and Compounding Division. “Not only are we seeing an increase in activity among customers in ordering new lines, we are noting and responding to a need for larger systems capable of higher-than-ever production rates. At one time, the industry standard was lines rated at 50-60 tons/hr. Now we are supplying machinery with capacities up to 100 tons/hr and more.”

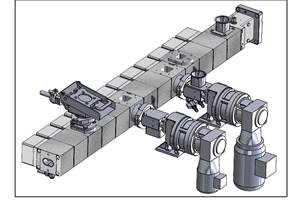

In North America, another key trend Bartel sees unfolding is demand from customers for turnkey systems—not just materials handling, conveying and compounding lines—but plant design and fabrication as well. At its booth at NPE2018, Coperion will demonstrate those capabilities in a virtual reality demonstration, like it did at the last K Show.

“We don’t think of ‘turnkey systems’ as just equipment,” Bartel explains. “Obviously we can engineer complete systems that include our own materials handling, conveying, feeding and extrusion technology. But turnkey to us is more than that. It’s about working with a customer to build a plant from the ground up. We’ve had these capabilities for years, but over the last year or so, we are having more customers asking us to get involved in projects at the very early stages because they realize we can offer a full package that saves them time and money.”

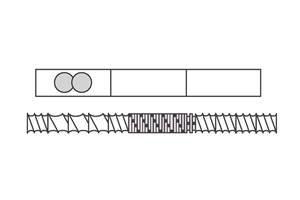

In engineering thermoplastics compounding, Bartel is seeing an increasing need for flexible systems that can be quickly turned around as compounders are being pushed to run smaller lots in various formulations. The STS Mc11 twin-screw extruder at its booth has a variety of new features that significantly improve the system’s handling and ease of cleaning.

Bartel’s counterpart on the pneumatic conveying and feeding side, John Fisher, president of Coperion’s Equipment and Systems Division, also notes the need for more flexible systems among custom compounders. Coperion K-Tron feeders are used in a wide range of industries outside plastics. For example, the company is displaying a Bulk Solids Pump (BSP) feeder that’s also used in the non-wovens industry, which places a lot of emphasis on cleanability and accuracy. Flexibility is also behind Coperion’s pneumatic-conveying demo, which Fisher says offers compounders “a spectrum between dilute and dense-phase conveying.” The unit is constructed to allow visitors to see particle flow through the system to show how different conveying methods are suitable for premixed materials; materials with high bulk density; and materials which are abrasive, friable, or tend to segregate.

Meantime, the North American plastics industry expansion has convinced Coperion to look at strengthening its capabilities at its Wytheville, Va., plant, which currently consists of two buildings and 100 employees. The firm is exploring doing more machinery manufacturing there, for both its ZSK and STS machine lines. It is also working with Bluefield College, in Bluefield, Va. and various local community colleges to develop a plastics curriculum.

Related Content

Configuring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreStandardized Extruder Can Be Used Anywhere

Machine can be manufactured anywhere the customer is with the same specifications, design, support and goal to advance their materials.

Read MoreStrategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

Read MoreNew Machines, Spare Parts and Auxiliaries for Compounding

NPE2024: ENTEK displaying a range of products at the May show.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More