New Machines, Spare Parts and Auxiliaries for Compounding

NPE2024: ENTEK displaying a range of products at the May show.

ENTEK is featuring new twin-screw extrusion equipment and technology, new replacement wear parts with an interactive screw design display, and new material handling equipment at NPE2024.

Twin-screw machinery equipment news will include:

- Updates on the company’s new -high output HT 162 twin-screw extruder, which is in production and scheduled for shipment in Q1 2025.

- Announcement that another new ENTEK twin-screw extruder, the HT 92, is now in development.

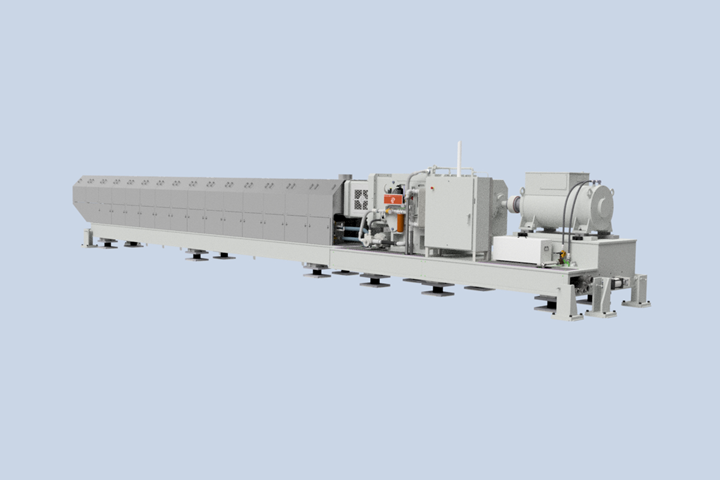

ENTEK’s twin-screw extruder product line continues to grow. The new HT (for high torque) line, which began with the introduction of the HT 72 machine in 2020, is being expanded with the development of the new HT 162 (photo) and the newest machine, the HT 92. News on the HT line expansion will be released at the show.

Twin-screw machinery technology displays include:

- Vent flow sensor technology mounted on a 103-mm twin-screw extruder barrel.

- VFT twin-screw machinery compounding technology for increased output and improved product quality.

- 37 mm QC3 stuffer, with mounting arm and 4 × 43-mm twin-screw extruder barrels (to show reach/flexibility) as well as ease of switching between vacuum stuffer and side feeder.

- ENTEK twin-screw extruder machinery controls.

ENTEK will be focusing on its technology offerings for twin-screw extrusion at NPE. All of these technologies are designed to improve productivity and end-product quality for compounders.

Replacement wear parts displays include:

- Screw layout program 2.0

- New features added since 2018 launch

- Live demos / interactive station

- 162-mm screws

- 133-mm screw set on shafts

- 27-mm screw set on shafts

- Many wear parts, including 250-mm screws, 82-mm round barrel, 160-mm barrel holders and more

Material handling displays will include:

- Filter receiver

- Vacuum loader

The vacuum loader and filter receiver from ENTEK Adaptive are designed for difficult-to-handle materials, focused on powders. The systems can be sized from 100 to over 40,000 lbs/hr depending on the customer’s need. Long-lasting filter life and easy-to-change filters can be seen on the equipment.

Related Content

-

Sirmax Adapts Integrated Recycling Approach to US Supply Conditions

Integrating compounding and recycling to leverage untapped postindustrial recycling feedstocks.

-

Strategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

-

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.