ENTEK Manufacturing

200 Hansard Ave.

Lebanon, OR 97355 US

541-259-1068

tstraw@entek.com

entek.com

About ENTEK Manufacturing

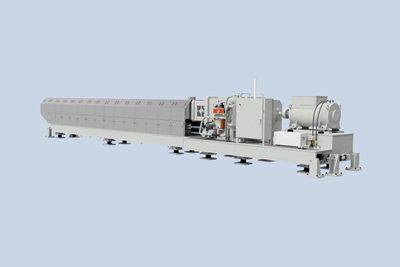

ENTEK has been manufacturing and selling extrusion equipment to the plastics industry for over 25 years. We listen to your needs and we encourage collaboration so that we can provide the best extrusion solution for your specific application. We pride ourselves on being vertically integrated to ensure first class quality and service in all we do. This means that you have access to the person who designed your extruder, the person who machined your screws and barrels, the person who wired the electrical panel, or the person who programmed your HMI. All ENTEK machinery and equipment is proudly manufactured in the USA at our campus in Lebanon, Oregon.

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

ENTEK Manufacturing Supplies the Following Products

- Bag and Drum Dumpers

- Blenders (non-intensive)

- Box Tilters

- Conveying Equipment (pneumatic and Mechanical)

- Feeders

- Hopper Loaders

- Hoppers, Bins, Tanks

- Intensive Fluxing (melting) Mixers

- Metal Detectors, Separators

- Metering, Proportioning Equipment

- Multiple-screw Extruders

- Rebuilt Screws or Barrels

- Screws (Plasticating)

- Semi-bulk Containers

- Silos

- Valves, Gates, Diverters

- Weigh Scales

Editorial, News, and Products

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

New Machines, Spare Parts and Auxiliaries for Compounding

NPE2024: ENTEK displaying a range of products at the May show.

-

Program Helps Compounders Configure Screw, Barrel Layout

New software from ENTEK is said to make it easier for compounders to design their own screw and barrel configurations.

-

How to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

-

Extruder Builder ENTEK Starts Wear-Parts Division

Division will make replacement wear parts for all twin-screw extruder brands. Tammy Straw named director.

-

ENTEK Expanding in Machinery, Battery-Film Processing

Showcases new plant to support machinery business, announces plans to build bigger compounding extruder and lays out strategy to build two new battery-separator plants.

-

ENTEK Manufacturing Names Three New Vice Presidents

Extrusion machine builder promotes three veteran employees.

-

High-Torque Twin Takes Aim at High-Volume Operations

72-mm machine—first in a series—targets high-output commodity and masterbatch compounding applications.

-

ENTEK Buys Material Handling & Conveying Company

Compounding machinery builder acquires Adaptive Engineering & Fabrication, which specializes in difficult to handle and convey materials.

-

ENTEK Opens New Plant in Nevada

Builder of twin-screw compounding extruders says it needs extra space to meet demand.

-

High-Torque Twin & Novel Feeding System Debut for Compounding

ENTEK takes the wraps off three innovations aimed at increasing productivity.

-

Biopolymer Compounding Done Right

Biodegradable polymers like PHA are set to slowly take over many areas of plastic production, but the material properties mean that special attention must be paid to the screw configuration and ventilation when compounding.

-

Biopolymer Compounding on a Twin-Screw Extruder: Four Things You Need to Know

Global bioplastic production capacity is expected to increase to 4.8 billion lb by 2024, driven by OEMs and brand owners steadily converting applications to these “green” materials. If you’re looking to supply compounds to meet this demand, here are some key processing considerations you need to know.

-

Connected Compounder

Fast-growing Alterra strives for “best-in-class” manufacturing operations driven by a custom-made Industry 4.0 platform.

-

Entek Names New President

Kimberly Medford promoted from v.p., general counsel to succeed Dr. Kirk Hanawalt, who retired earlier this year.

-

ENTEK Promotes Campbell to V.P., Sales

Thirty-year veteran of machine builder advances from director of sales.

-

Growing Compounder Targets Tolling

Illinois-based compounder BPC boosts capacity with high-output twin-screw to target more toll-compounding business.

-

ENTEK Expands Extruder Lines for Both Small Lot and High Throughput Jobs

New compounding extruders for both quick-change and high-volume applications.

-

Extrusion/Compounding at NPE2018: More…More…More!

More speed, flexibility and robustness. Across a gamut of extrusion applications, machine builders are introducing new machinery, components, and systems to dramatically raise the bar on productivity.

-

NPE2018 New Technology Focus: Compounding

Check out what’s new in compounding at this year’s big plastics industry trade show.

-

Flexible Twin for Small-Lot Compounding, High-Output Extruder

ENTEK displaying two new twin-screw extruders in an interactive display that also features its screw layout program.

-

Entek Announces Staff Changes

Compounding machine builder reshuffles sales and marketing team.

-

Pellet Production Is a Blast For This Processor

Maxi-Blast opens a plant with brand-new equipment to produce its own pellet blasting media.

-

EXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

-

EXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

-

2013 was good for N.A. equipment suppliers; Can 2014 Overcome a Slow Start?

The North American plastics equipment market saved its best for last in 2013, delivering shipments valued at $335.1 million in the fourth quarter—the best three-month stretch of the year and up 3% from the previous quarter. Will that momentum hold in 2014, however?

-

Now You Can Refurbish Twin-Screw Elements

Two suppliers of twin-screw compounding extruders announced at NPE2012 that they are now offering screw-element refurbishing services.

-

Wood-Plastics Composites Done Right

Mixing and extruding wood fiber in a plastic matrix is technically demanding. It requires careful attention to formulation, drying, and extrusion temperatures

-

Extrusion & Compounding at NPE: More Output, More Flexibility, Less Energy

There won't be many blown-film lines running, but there is still much in the way of innovation going on in extrusion and compounding.

-

NPE 2009 Wrap-Up: New Machinery for Extrusion and Compounding

Extrusion machinery at the June NPE show in Chicago showed inventive ways to get more out of your floorspace and materials.

-

NPE News in Compounding

Compounding news at the show includes several new ways to feed low-bulk-density materials faster for higher outputs with corotating twin screws.

-

What to See at NPE 2006: Compounding and Mixing

Throughput capacities are going up for compounding equipment of all types.

-

NPE News Wrap-Up: Extrusion

Gearless extrusion, cryogenic profile calibration, wireless data communications, and automatic start-up of blown film lines are just a few of the new ways to raise efficiency and output that were highlighted at NPE.

-

NPE Highlights Compounding's Growth Niches

Show exhibitors say long-fiber wood composites, direct extrusion/compounding, and reactive compounding are where the action is.

-

Torque & Speed How Much Is Enough?

You may be thinking of buying one of the new ‘high-torque/high-speed’ twin-screw compounders in order to raise your output without going to a larger machine. But how much torque or speed do you really need? Underusing a high-powered extruder wastes investment dollars. So look carefully at what is required for the materials you run.

-

Twin-Screws & Kneaders Pack More Muscle

This K show demonstrated the continuing evolution toward higher torque, screw speed, and throughput rates in twin-screw compounders. There were also new developments for reducing wear when processing filled compounds and new processes available for license to compound wood and paper fibers with plastics. There were even some improvements in backflushing screen changers.