Program Helps Compounders Configure Screw, Barrel Layout

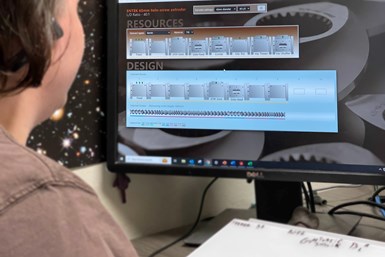

New software from ENTEK is said to make it easier for compounders to design their own screw and barrel configurations.

ENTEK Manufacturing has introduced an updated version of its original Screw Layout Designer program. Screw Layout Designer 2.0 is said to offer numerous new features that make it easier for compounders to design the optimum screw and barrel configurations for their ENTEK twin-screw extruders.

Screw Layout Designer 2.0 is the first major upgrade of the original Screw Layout Designer launched by ENTEK in 2018. The original program was designed to enable customers to input screw and barrel layouts to create the optimum screw configuration for their specific twin-screw extruder application. After inputting all relevant data, the program produced both visual drawings and spreadsheet layouts.

There are several built-in features for this software, including a drag-and-drop functionality on all components that customers need to specify, such as barrel sections, screws and metallurgy. There is also automatic calculation of remaining space on the screw shafts and safeguards that alert the designer when putting certain elements where they should not go.

Photo: ENTEK

After gathering information from 5 years of use in the field and listening to customer input, ENTEK’s new Screw Layout Designer 2.0 includes the following new features:

- Metallurgy shown visually for barrels and screws, with key at bottom.

- Incompatibilities trigger pop up warnings as they occur in the layout and are listed on the printed or saved layout.

- Ability to include materials and item numbers on printed or saved layout for ease of ordering replacement parts.

- Can easily change settings for extruder diameter and length.

Screw Layout Designer 2.0 is for use with all models of ENTEK twin-screw extruders. ENTEK manufactures extruders ranging from 27 mm to 133 mm.

Related Content

-

More Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

-

How to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

-

How to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.