Smaller Screws Impose Bigger Challenges

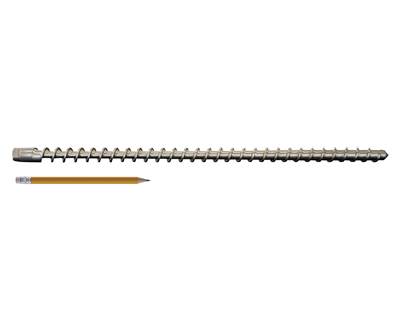

Very small extruder screws work just about like their larger cousins, but some critical differences make them harder to design and machine.

The rapid growth in additive manufacturing (also known as 3D printing) has led to increased demand for some very small extrusion equipment. How small is small? An extruder smaller than 1.5 in. diam. is more complex to design and build than bigger machines, which takes some people by surprise

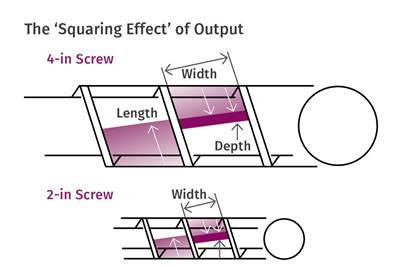

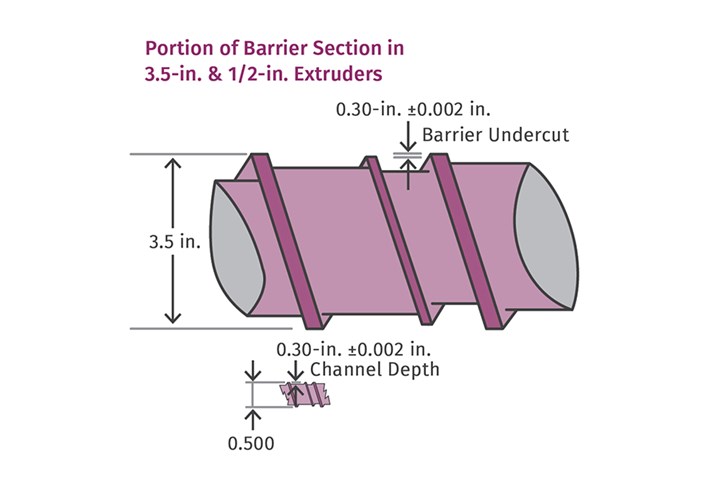

How can this be? Well, for one thing, the barrier clearance for a typical 3.5-in. screw is about the same as the channel depth in the metering section of a ½-in. screw. Typical machining tolerances for a 3.5-in. screw would be ±0.005 in. in the metering section, but for a ½-in. screw that tolerance would be around 32% of the channel depth, which would affect output and melt uniformity.

The necessity for tighter tolerances adds significantly to the cost of small screws. Additionally, the machining time is not reduced anywhere near in proportion to the size, as the screw simply must be machined with much smaller cutting tools.

The accompanying illustration is a 3.5-in. portion of a barrier section and a ½-in. portion of a barrier section drawn to scale. The ½-in. screw configuration is hard to even see, so can you imagine how hard it is to machine.

Because of the small size, another critical area for dimensions is the feed-section geometry, particularly the channel depth. The channel areas are so small that the size and shape of the polymer particles have a much more significant effect on the feed rate. I have even found it necessary to get pellet samples and construct trial channels to see how many pellets would fit. A relatively small change in depth or pitch can significantly alter the amount of material the feed flights can accommodate, which ultimately is reflected in the output. In some cases, special pellet sizes are required.

Because of the small root diameter in the feed section, it is important to calculate the torsional strength of the screw in the feed section vs. the overall performance requirements to minimize screw breakage. High-strength alloys are required in many cases to obtain sufficient strength in the screw. A ½-in. screw will typically require only about 1 hp for full output capacity.

The small size precludes any type of welded wear-resistant flight surface such as Stellite or Colmonoy, so screws must be nitrided or made of heat-treated tool steels. That’s also true of the barrels, which are too small for abrasion-resistant cast liners.

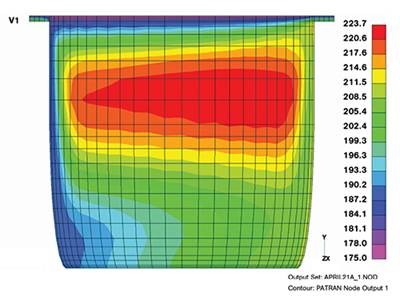

One favorable aspect of small screws is that melt temperature is easier to control because there are only very thin polymer layers in the screw channels. That makes heat transfer to or from the barrel to the polymer much more effective. As a result, power requirements are typically reduced and barrel cooling is more effective. This is particularly advantageous for extruders made for additive manufacturing because they have to stop and start at each point of deposition, making the barrel a stabilizing heat sink.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 50 years. He is now president of Frankland Plastics Consulting LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreRead Next

Unraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

Read MoreWhat You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

Read MoreThe Role of Screw Design In Efficient Extrusion Of Medical Devices

For extruders of medical tubing, screw design plays a key role in maintaining dimensional control, physical properties, and more.

Read More

.jpg;width=70;height=70;mode=crop)