Solving Gravimetric Blender Problems

Gravimetric blenders offer plastics processors considerable savings.

Gravimetric blenders offer plastics processors considerable savings. Their tight control over expensive additives eliminates the need to overfeed in order to maintain a minimum specification. For example, eliminating a 1% overfeed of a $5/lb additive on a machine running 100 lb/hr can save up to $30,000/year for a three-shift operation. At this rate, the gravimetric blender can pay for itself in just three to six months.

But if your blender is not properly maintained, its accuracy may be compromised and you may not see the expected savings. Here are typical examples of maintenance-related issues that can arise with gravimetric blenders.

Problem: Our blender’s usage of material is different from the inventory level displayed on the blender control. What is causing the discrepancy?

Cause: Improper calibration of the load cells is the most likely culprit. When was the last time you calibrated the blenders? We often find blenders that have been installed and used for quite some time without routine maintenance.

With gravimetric batch blenders, the ratio of materials used is constant because all materials are weighed in a common weigh hopper by one or two load cells. The first indicator of a calibration problem would be a disagreement between the blender inventory and the actual material usage.

With continuous loss-in-weight blenders, each component is equipped with its own load cell. While this allows accurate metering of very low percentages (less than 1%) of additives, calibration problems cause both the ratio of the blended material and the inventory level to be off. If the calibration is off substantially, product quality may suffer. For instance, too little color concentrate is easily visible, but too much color may not be apparent but could alter the mechanical properties of the finished product. Such a problem often is not discovered until long after the product is shipped to a customer.

Weight measurements will not be reliable if load cells are not properly calibrated to a known weight. Moderate inaccuracies may be hard to see in the end product. If an important component is off by a significant amount, bad product will result or money will be wasted on excess material.

Damaged load cells can be detected during routine testing. Load cells can be damaged when stepped on or run into with equipment or boxes or used as a grab handle. A power surge or excessive static electricity can harm them, too.

Solution: Regularly calibrate each of the blender’s load cells using a calibration weight of a known value. The process takes less than 5 min and can usually be completed without shutting off the process machine. When accuracy or documentation is critical, calibration should be checked once per shift or once per day along with actual material inventory. In less critical situations, monthly calibration may be sufficient.

Networking and remote monitoring centralizes control of the blender so the supervisor can monitor all blenders from a remote location and can select how often data is gathered. Batch-to-batch consistency can also be documented.

Problem: We are experiencing inconsistent material metering and too-frequent alarms. Cause: Check the quality of your air supply. The pneumatic slide gates that are used to meter materials will not operate properly if dirty air is being used. “Dirty” air might contain water, rust, and/or other contaminants. Symptoms to look for include discolored air lines, premature cylinder wear, and cylinders that sound like they are sticking when cycling. If the lines contain foreign material like dried oil or sludge, you can often hear the cylinders stick, then break loose and slam open or closed. Also, watch to see if the gate is opening and closing properly.

If air quality is really poor, the blender’s filters may become plugged in less than a day, even in just an hour. The pneumatic valves have small ports that plug easily, so be sure the filter element is always in place and properly maintained.

In addition, verify that your vacuum-loading receivers are sealed and vented properly, so a vacuum is not created in the blender supply hopper. This will prevent material from feeding when the metering gate on the blender opens.

Solution: Ensure a good, clean air supply by adding an additional filter, a better filter, or both to the air-supply line at the blender—or better yet, at the air compressor, where it will clean up the air supply for the whole plant. Also verify that there is proper sealing of the vacuum-receiver flapper and proper venting of the supply hopper.

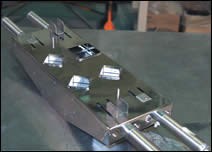

Problem: Occasionally the air cylinder disconnects from the metering gate. What could be causing this?

Cause: The most likely cause is loose parts. Locking devices are used to assemble the blender, but after maintenance they may not be put back together correctly. Also, vibration from the molding machine, can loosen parts over time.

Solution: When starting a shift, take a couple of minutes to look over the equipment to be sure everything is working as it should and that no parts have become loose. There are no hidden parts, so potential problems should be easy to spot.

Problem: One of our operators has blue color from the previous job showing up in the red material of his current job.

Cause: An incomplete or improper cleanout will allow ingredients from the previous job into the next job.

Solution: When switching jobs, drain the hoppers and either blow them out or use a shop vacuum to thoroughly clean them. Be sure to clean the vacuum receivers as well as the corners of the supply hoppers, and thoroughly clean the metering-gate assemblies and mix chamber. If the blender has a surge bin underneath, don’t forget to clean that as well. If any of the hoppers or other components seem to be coated with dust from a previous material, wipe it down to be sure all residue is removed. A thorough blender cleanout takes just 5 to 10 min and may be most conveniently done while changing molds.

Problem: One of the guys here at the plant wants to bypass the safety circuit switch. Warning: Doing so would present a real danger. An operator could be seriously injured. The safety circuit is there to protect the operator from the slide gates that meter the material and from the rotating mixer. If the operator were in the mixing chamber cleaning out the blender or making a repair, an inactive safety circuit could allow the slide gate to close or the mixer to turn, causing injury.

Solution: Inspect the safety circuit once a day or once a shift. To confirm that the safety switch is operating, open the mix-chamber door. The blender should stop immediately. Because the power to the blender will be killed, test the safety circuit right after a batch has been dumped so the batch is not affected.

Keith Larson is product manager for material handling systems at AEC Inc.’s training and R&D center in Flint, Mich. He can be located at (810) 720-7300

Related Content

Looking to Run PCR on a Single Screw? Here’s What to Keep in Mind

Just drop it in and mix it up? Sorry, there’s a lot more to it than that. Here is some of what you need to consider.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreReversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

Read MoreOptical Sorting for Color Flexibility in Recycled Plastics

Aaron Industries added optical sorting to its operation, expanding capabilities to meet the color needs of customers.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More