Technology Takes Aim At Drying Specialized Resins

Novatec develops new at-the-press drying solutions for molders tackling highly tailored nylons and other specialty materials.

An increase among molders in running highly tailored nylons—some for the first time—has encouraged one machine builder to develop features aimed at ensuring these materials are dried properly. Novatec Inc., Baltimore, will debut these technologies May 7-11 in Orlando, Fla. at NPE 2018.

“Over the past few years, we’ve seen hundreds of specialty nylons developed for a range of markets that include automotive—where lightweighting is the driver—medical, packaging and more,” remarks Mark Haynie, Novatec’s dryer product manager. “And as the business of molding commodity resins has continued to move offshore, we’ve seen quite a few molders taking on projects running nylons and other thermally or visually sensitive resins like PBT, PETG, and others for the first time.” What’s more, adds Haynie, these molders are typically using press-side dryers—more typically associated with drying commodity materials—to dry these materials.

Drying nylon can be tricky business, Haynie points out. Most engineering resins require drying to 100 ppm. Nylon drying specifications, on the other hand, are roughly 500-800 ppm. Molders not accustomed to these parameters tend to overdry the material, which invariably will make the part brittle and fail. “In some cases, nylon straight out of the gaylord does not have to be dried at all,” states Haynie. “But still, if the molder’s procedures say the material must be dried, that’s what they will do.”

As a result, Novatec has taken two technologies established in central drying and adapted them to its line of NovaWheel portable dryers: Moisture Manager and OverDry Protection. Says Haynie, “These methods are much more effective and advanced than common features like dewpoint control and temperature setback. Moisture Manager and OverDry Protection are both designed to ensure that the dryer automatically responds to changes in resin moisture and ambient conditions that can lead to improperly dried resins. They have features that eliminate the possibility of overdrying nylons and other sensitive engineered resins. Plus, the technology controls the drying temperature to limit or eliminate the possibility of discoloration or polymer breakdown in thermally or visually sensitive resins like PC, PET, ABS, and other translucent and colored resins.”

Questions about Drying? Visit the Resin Drying Zone.

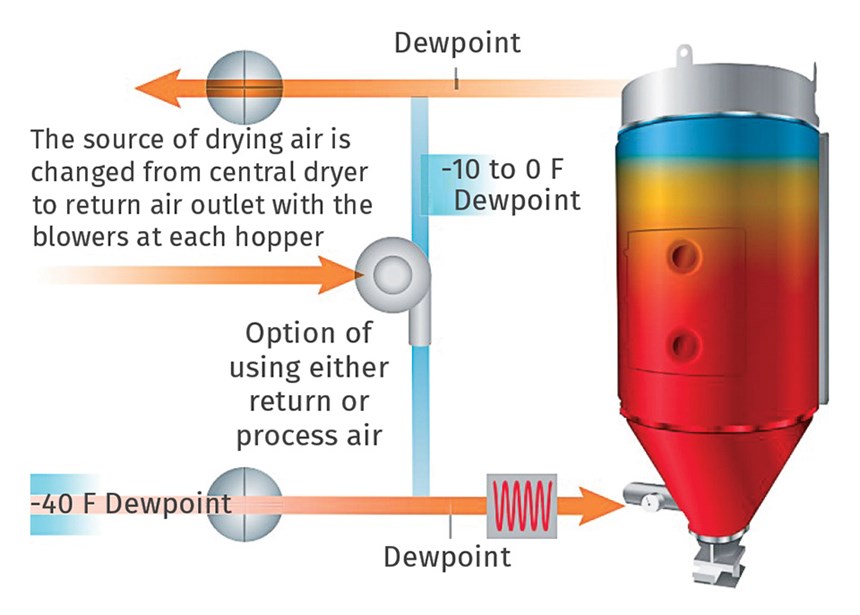

Novatec’s Moisture Manager uses valves in the dryer and a dewpoint measurement out of the drying hopper to determine if moisture is being pulled from the resin, or if the resin is already dried to the appropriate moisture level. If the resin is already dry, the blower loop will exclude the desiccant and recirculate and heat without using dry air at -40 F/C dewpoint. If, however, the moisture monitor in the hopper outlet senses that the resin requires additional drying at any point, dry air is introduced into the loop automatically, and then bypassed again automatically when the desired dryness is achieved. Each resin can have a recipe that ensures proper resin moisture always.

This is significantly different from running the dryer at a fixed dewpoint other than -40 F/C, where operators must first determine that they need to start the dewpoint change and then figure out—mostly through trial and error—what change is required. In doing this manually, operators will wind up making many bad parts first and then experiment on what they need to do to correct the issue. Moisture Manager does this automatically.

OverDry Protection is an automated control process that takes the guesswork and human intervention out of the process.

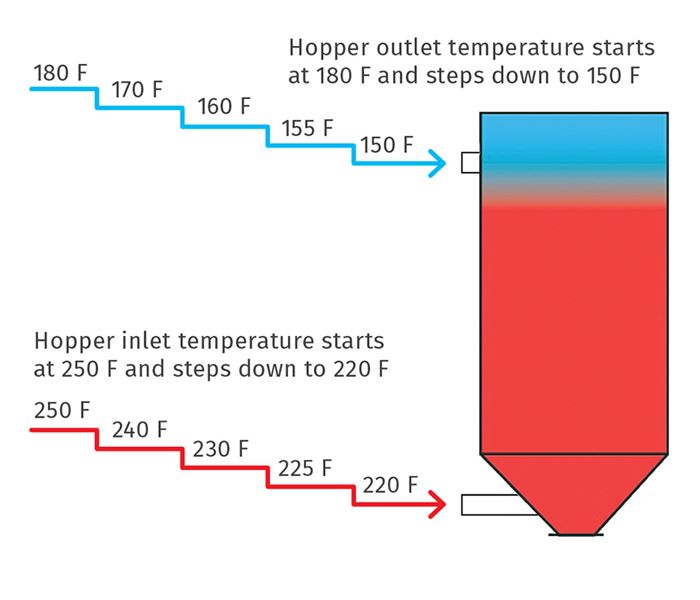

As for OverDry Protection, once this feature is turned on, the dryer will automatically adjust the drying setpoint parameters to maintain the correct drying temperature based on an algorithm in the control program. Once the operator inputs the desired drying temperature, the dryer control takes it from there, determining the appropriate hopper exit temperature at which the drying temperature should be reduced, and find automatically the temperature that gives the proper temperature profile in the hopper. No further intervention is necessary, and the dryer will automatically adjust and maintain the temperatures to have a consistent drying-temperature profile.

In cases where operators change a gaylord or resin source—and the resin temperature or moisture is different from the previous lot—the dryer control automatically adjusts to maintain the temperature profile. Competing temperature-setback features require operators to determine the temperature at which the drying temperature should be lowered and to what temperature it should be reduced. OverDry Protection, on the other hand, is an automated control process that takes the guesswork and human intervention out of the process. OverDry Protection will be standard on Novatec’s NovaWheel portable dryers; Moisture Manager will be available as an option.

NITROGEN DRYING

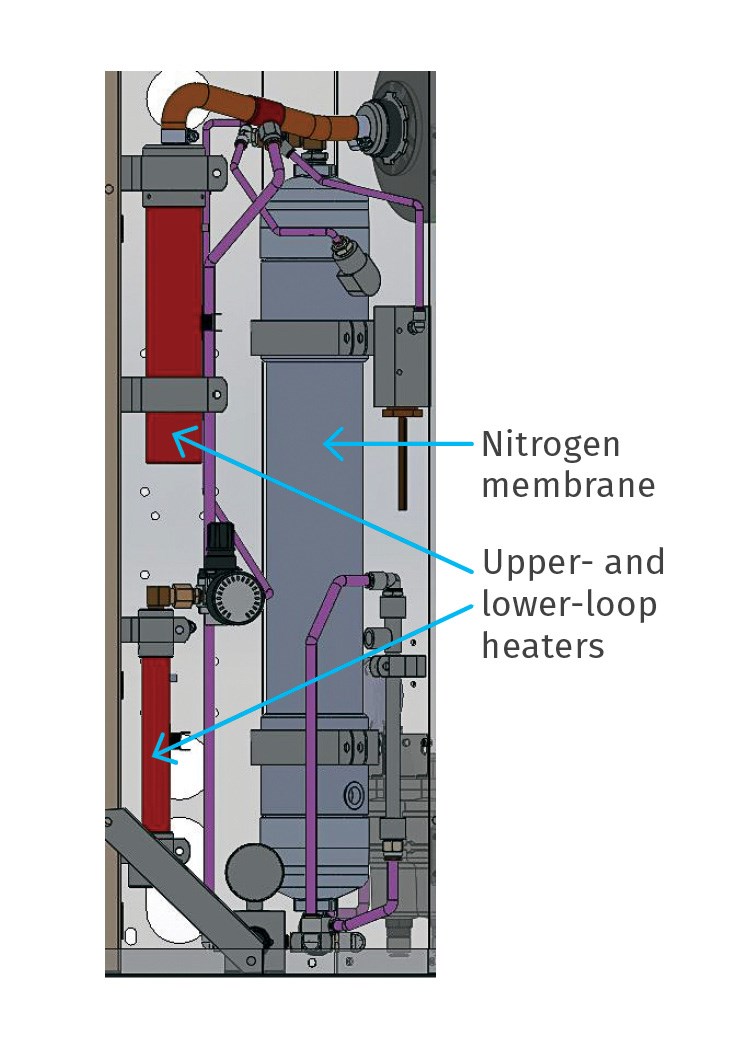

At NPE 2018, Novatec will also take the wraps off a new Nitrogen NovaDrier. As with the Moisture Manager and OverDry Protection system, this technology was also developed in response to increased use of polymers with unique properties that can be diminished if not handled properly during the drying process.

The dryer introduces an inert gas or nitrogen to inhibit the oxidative degradation of polymers. Resins that tend to degrade with prolonged exposure to heat in the presence of oxygen include nylons, PBT, PLA, and TPUs. A loss in properties due to oxidation occurs more readily in the presence of the heat used in drying. Each polymer has different limits on temperature and the amount of degradation that occurs with exposure to heat and oxygen during drying.

Typically, the drying temperature can be 10-50° F higher with a nitrogen source in lieu of air, allowing for shorter drying times. These shortened exposures lead to better polymer performance in terms of strength, ductility, color/clarity, viscosity, chemical resistance, stiffness, and stability.

Using nitrogen in dryers is not altogether new. This dryer is unique, however, in that it requires no handling of cryogenic nitrogen or bottles. There isn’t any need to have both the handling and risk of using bottled nitrogen.

This dryer uses standard plant compressed air as the feedstock, from which it extracts the nitrogen for drying, so only air is released from the dryer unit (in two streams, one oxygenrich, and one nitrogen-rich). This approach eliminates the hazards involved with venting of nitrogen into a closed area. It can be used anywhere without special procedures or handling, Novatec says.

Related Content

Bozzelli’s Guide To Specifying a Dryer

Here's a list of 17 things to do when looking for new drying equipment.

Read MoreNovatec Announces Deal with Moisture-Analysis Specialist

Novatec will be aboni’s exclusive distributor in North and Latin America for offline moisture analyzer.

Read More'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

Read MoreWheel Dryers for Beside-the-Press, Small Central Applications

Precision control on the dryer series reportedly prevents the thermal, chemical and physical material degradation that can result from long drying times at high temperatures and high air flow.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More