Tests Show Direct-Drive Extruders Are Quieter, More Energy Efficient

Green machines may be coming to extrusion.

Green machines may be coming to extrusion. Processors that opt for direct-drive extruders can expect quieter and more energy-efficient operations. Such was the conclusion from a series of tests conducted recently by leading extruder manufacturer Davis-Standard LLC, Pawcatuck, Conn. (davis-standard.com).

The study examined three different types of extruder drive and motor configurations for single-screw machines. Two of the three were conventional designs utilizing an AC or DC motor with a mechanical gear reducer. The third was a permanent-magnet, synchronous motor—a high-power-density unit that does not require a mechanical gear reducer to multiply the torque to rotate the screw.

D-S tested the systems on its Thermatic 2.5-in., smooth-bore extruder with 30:1 L/D. The screw was its DSBM low-intensity barrier design. Two different materials were used: Equistar’s Petrothene LR732001, a 0.3 MI HDPE that is considered a “high-torque” material; and LyondellBasell’s Pro-fax HP640H, a “low-torque” PP homopolymer with a 2.0 MFR. In both cases, the extruder was set at the same temperature profile regardless of the drive configuration. The test was run at six screw speeds from 25 to 150 rpm.

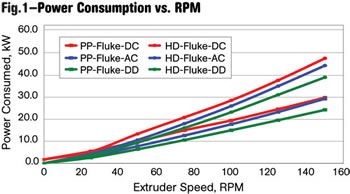

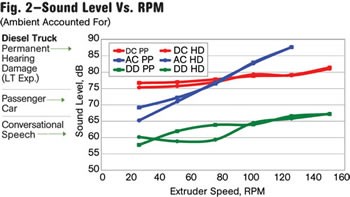

The data recorded at each operating condition included the extruder output, melt temperature in the center of the melt stream in the die adapter, motor power consumption, heat flux in each barrel zone, and pressure readings along the barrel. The pressure readings were recorded with a data-acquisition system at a rate of 50 Hz. Electrical measurements were made using a Fluke 435 Power Quality Analyzer; sound-level measurements were taken using a Bruel & Kjaer Type 2236A-007 Type 1 precision integrating sound-level meter.

The results revealed that the direct-drive system is more energy efficient and quieter than its AC or DC counterparts. For each of the screw speeds and materials tested (see Fig. 1), the DC system consumed more power than the AC system, and the AC system consumed more power than the direct drive. At a typical operating condition of 100 rpm—the base speed of all of the motors used in the experiment—the DC system consumed 10% more power than the AC, and the direct drive consumed 10% to 15% less than the AC

The direct-drive system also was much quieter than the conventional systems—up to 70 times quieter than the AC at 100 rpm.

Despite these benefits, direct-drive systems are still in their infancy in North American extrusion. Price has been one constraining factor—for example, a 3-in. extruder with direct drive costs about $20,000 more than a conventional machine. Direct drives are limited to use in extruders up to 4.5-in. diam. Also, they cannot be operated more than 15% to 20% faster than the base motor speed. Other suppliers question whether the same energy efficiencies are attainable beyond typical operating speeds.

Davis-Standard presented its findings in May at the SPE ANTEC conference in Orlando, Fla. The paper was co-authored by John Christiano, v.p. of process technology, and Dr. Jason Baird, process development engineer.

Related Content

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

-

Single vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

-

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.