Troubleshooting Mold Temperature Control

Mold-temperature control is just one of many process elements that can affect the quality of an injection molded part.

Mold-temperature control is just one of many process elements that can affect the quality of an injection molded part. Even within that relatively narrow slice of molding technology, the number of different variables is almost innumerable. We will limit scope of this article, therefore, to some of the basic causes of three different classes of quality problems: problems that appear during start-up, problems that appear suddenly, and problems that develop over time.

We will assume that we are dealing only with cold-sprue molds, as hot-runner systems only add more variables to an already complex subject. We will also assume that the injection molding machine is correctly set up, that cooling times and overall cycle times are reasonable, and that the resin is properly heated prior to injection. In other words, we will assume that any quality problems observed are related to mold temperature.

In a perfect world, anyone running a particular mold would know what the mold designer set as the ideal temperature and flow rate for the cooling water. In reality, operators and setup personnel don’t always know these settings and/or something changes so that it is necessary to re-establish them by trial and error.

Quality problems related to heat transfer in the mold tend to arise from improper polymer flow in the tool due to over-cooling or under-cooling. The latter condition would apply when parts are not completely solidified and therefore stick in the mold or deform after being ejected from the mold. Over-cooling may be suspected when some or all of the mold cavities do not fill properly. Surface detail may not be perfectly replicated or, worse, parts may be incomplete (short shots). Shrinkage or warpage could result from over- or under-cooling or could be due to uneven cooling.

POOR PART QUALITY AT START-UP

If you begin a production run and immediately notice problems that you suspect are due to a heat-transfer problem, here are a few questions to ask:

•Was the cooling system checked? It sounds ridiculously simple, but is your heat-transfer system actually working? Check that all hoses are properly connected and that there are no leaks. Then, starting at the mold, make sure all the components in the system are working correctly. If you have a mold-temperature control unit (TCU) between the mold and the chiller, make sure the heater and pump are working. Until the mold is up to temperature, the TCU will need to heat the heat-transfer fluid and it can’t do that if the heater isn’t functioning. Then check the cold-water source (chiller or cooling tower) and make sure they are operating correctly.

•Was the tool changed? If so, then make sure that all temperature and flow rates are optimized for the new mold. Different molds often require different heat-transfer settings and if the tooling was changed but the heat-transfer settings from the previous job remain, the system won’t be able to produce good parts. It is also possible that a TCU that works well with one tool or process may not be capable of handling a larger tool effectively. And don’t forget to make sure that the mold cooling lines have been purged completely of any air before start-up. Air in the tool will inhibit proper heat transfer.

•Are you actually getting the temperatures and flow rates specified? Simpler chiller and TCU controls don’t always display actual temperatures and flow rates, so it is a good idea to double check. Use a contact or strap-on thermometer (or an infrared temperature gauge, if you have one) to check the temperature at the mold and at several other points in the system. Check the temperature rise from where the heat-transfer fluid enters the mold to the point where it exits the mold. If the temperature delta is less than that specified by the mold maker (or less than experience would suggest it should be), this may signal that something has happened to limit fluid flow.

Some TCUs are equipped with a flow meter showing gallons or liters per minute, or one can be plumbed into the system temporarily or permanently. If you don’t have a flow meter, you can still check flow rate by running the process fluid into a pail and timing how long it takes to fill. Divide 60 by the number of seconds it took to fill the pail and multiply by the volume of the pail and you’ll have a good approximation of your flow rate in gal/minute.

•Do you have turbulent flow? Remember that the fluid flow rate, in combination with the length and diameter of the cooling channels and a few other variables will determine if the coolant flow is laminar—flowing mostly in neat straight paths with a smooth, consistent motion—or turbulent. Turbulent flow is characterized by random eddies, vortices, and other flow instabilities that ensure the maximum amount of water comes in contact with the walls of the cooling channels, enhancing heat transfer between the fluid and the surface. Anything that reduces flow rate potentially limits turbulence and will dramatically reduce cooling efficiency.

If you have reason to believe that the flow rate is inadequate to achieve turbulence, you have a couple of options. If you want to use a portable chiller, it is best to use one that has dual pumps to ensure consistently higher flow to the mold. One pump is dedicated to recirculating fluid through the chiller evaporator, while the other provides the increased process flow to the mold. Alternatively, or if you are using a central chiller, a TCU can be used not only to fine-tune mold temperature, but also to act as a booster pump, ensuring adequate pressure and volume to create turbulent flow regardless of the load on the overall central chilling system.

•Is the TCU properly sized? Temperature-control units, as their name implies, have both heating and cooling capabilities to maintain a preset mold temperature over time. Early in a run, before the mold has absorbed heat from the polymer, the TCU circulates hot fluid to bring it up to temperature. Later, it can heat or cool the circulating fluid as necessary to maintain the correct temperature. Thus, TCUs are generally specified for their pump size (in hp or kW), their heater capacity (kW) and their cooling-valve size. Pump size dictates overall flow rates and pressures, while heater capacity will determine tool heat-up time and the maximum temperature that is attainable at a given flow rate. The cooling valve allows chiller or cooling-tower water into the system to keep mold temperature down. If your TCU is not properly sized—if, for instance, it is normally used with another mold with different heat-transfer requirements, its heating or cooling capabilities may be inadequate.

SUDDEN APPEARANCE OF COOLING PROBLEMS

Now assume that you started up your molding machine, established heat-transfer conditions that resulted in quality parts, and that you have been operating for some time without incident. All of a sudden, however, you begin to experience a heating or cooling issue. You’ve checked the setpoint and actual readings in the molding machine and the material temperatures, injection pressures, and cooling times are still within acceptable limits. So, you begin to suspect a heat-transfer issue.

Most of the issues that might have caused you problems during start-up also apply here, except that you can assume all your equipment is properly sized and that the basic configuration of the system is correct. A sudden change in heating/cooling operation signals a malfunction: A heater has burned out, a pump has failed, or there is a leakage or blockage in the fluid-circulating system.

To troubleshoot, you do the same things you might have done during start-up to confirm that your system was operating properly. Go back to the mold and check hoses and connections to make sure there are no holes or kinks in the hoses. Check the operating condition of the TCU and/or chiller to make sure each of their components is functioning. Check your cooling tower to make sure its fans are operating and that water is flowing to and from the heat-transfer equipment. If you are drawing city water into your system (as cooling water in a TCU, for instance), you may want to investigate whether the overall water-system pressure is at normal levels.

GRADUAL APPEARANCE OF COOLING PROBLEMS

While a sudden change in heating or cooling performance due to a malfunction may be relatively simple to diagnose, the gradual development of quality problems can be more insidious. In fact, you may have been compensating for a growing heat-transfer issue for some time—by changing other process settings, for instance—long before the problem became too serious to ignore.

That’s why it is best to keep a detailed log of the heat-transfer conditions associated with each mold you run. After you have gotten the process operating properly, record the heat-transfer system parameters that result in a stable process and quality parts:

•Composition of heat-transfer fluids in the system (water, 30% propylene glycol, type of oil, etc.)

•Process-fluid flow rates, temperatures, and pressures in and out of all heat exchangers, tools, and processes.

•Equipment in the system, including pump motor horsepower, actual electrical amps drawn, TCU heater sizes, and cooling-valve size.

•Ambient temperature when all of the previous data was recorded.

•Resin type and throughput rate.

These data should be logged every time a particular job is started up and anytime heat-transfer and process parameters are changed. Not only will this help you when you set up a job that has not been run for some time, it will also give you an historical record that could identify a gradual loss of system efficiency long before it becomes critical to part quality. Some of the problems such a log might signal include:

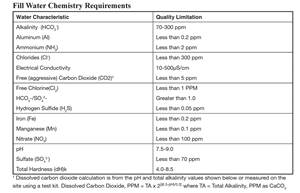

•Fouling of internal water lines in the mold. Suspended or dissolved solids can build up on channel surfaces, reducing fluid flow and limiting heat transfer between the steel and cooling water.

•Fouling of lines in cooling equipment. The same types of issues can apply to the heat exchangers and piping in chillers and TCUs. Filters can be used to remove many suspended solids, but dissolved solids like lime need to be addressed by a water-quality specialist familiar with the water in your region. In a closed-loop system, periodic checking of water chemistry and conductivity can also warn when dissolved-solids content is reaching problematic levels.

•Cooling-tower water contamination. A tower can become contaminated by all sorts of airborne debris (tree seeds, leaves, etc.), as well as algae. A full-flow strainer on the tower outlet can eliminate a lot of the problems, and a properly sized pump tank will allow solids to settle out of the water before it is pumped into the heat-transfer system. Here, too, it is important to watch dissolved solids. Towers cool by evaporation and solids can build up, so it’s a good idea to regularly replace a percentage of the water.

•Environmental issues. Ambient conditions can also affect the way an injection mold and associated heat-transfer equipment perform. Hot, humid summer weather can burden your heat-transfer system by adding to the heat load. In hot weather, heat transfer to ambient air is reduced and thus more heat needs to be removed by the system. In addition, outdoor cooling-system equipment efficiencies and capacities may be negatively affected by higher ambient temperatures and humidity.

Condensation that forms on cooling lines also diminishes efficiency. Every gallon of condensation reduces cooling capacity by half a ton. Conversely, ventilation around a mold or cooler weather can assist in mold cooling, reducing the burden on the system.

•Refrigerant leaks. A gradual loss of refrigerant pressure due to a slow leak will degrade chiller performance. Not only is it costly to repair the leak and replace the refrigerant, but many cooling gases (especially Freon used in older systems) pose an environmental hazard.

GOOD MANUFACTURING PRACTICES

The more you know about your heat-transfer system and the closer you monitor its operation on an ongoing basis, the less likely it is that you’ll deal with problems like those described above. Just as you keep a “recipe” for the injection molding machine setup for every job and every mold you run, you should also establish and maintain a baseline setup guide for your heat-transfer system that includes at least the following information:

•TCU model/capacity required;

•Chiller model/capacity required;

•Ideal flow rate through the mold;

•Key pressure drops;

•Key temperature drops.

Also, since efficient operation of your heat-transfer system depends on the equipment being in good working order, it is important to establish a regular maintenance program and to keep a maintenance log. Most reputable suppliers of heat-transfer systems can help set up such a program and provide service personnel to manage it.

Finally, make sure your operators are well-trained in the operation of heat-transfer equipment. The more they understand about why it is important to process efficiency and part quality, the better they will be able to use it properly and maintain the operation and maintenance logs mentioned above. Again, reputable equipment suppliers can help you develop an appropriate training program.

Related Content

Captive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

Read MoreTroubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.

Read MoreMulticoupling Range Extended

Hasco‘s quick-connect system for multiple cooling circuits has added U.S., French and HT versions.

Read MoreWater Temperature Control Upgraded and Integrated into Machine Control

Engel’s new eco-flomo temperature control system continuously monitors injection mold cooling and temperature control circuits, displaying pressure, temperature and flow rate values.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More