Follow This Action Plan to Keep Your Sheet Dies in Line

Getting back into production after maintenance or troubleshooting requires a coordinated effort. Here’s how to get your sheet line up and running as fast as possible.

Sheet processors know that the key to productivity is maximum extruder uptime. But even with equipment in prime condition, downtime is necessary for routine maintenance or to troubleshoot processing problems. Getting back into production fast requires a well-organized effort like that of a pit crew in auto racing.

The comparison is apt for routine die maintenance, where getting back into the race quickly is chiefly a matter of organization—establishing an action plan and safe handling practices, training the crew, and making sure the necessary tools are right at hand. But it’s more complicated when it comes to troubleshooting. Problems with product quality may arise from a wide range of causes, many originating not in the die but in the extrusion process or downstream equipment.

Normally, the toughest problems to solve are not those involving thickness variation. By using the adjustment components of the die itself—the restrictor bar, flexible lip, and temperature controls—operators can readily achieve gauge uniformity. The more complicated issues involve problems with sheet appearance or aesthetics.

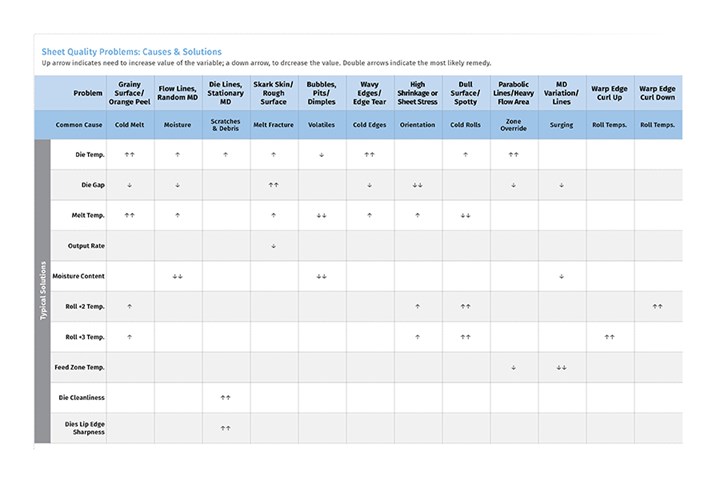

EDI has created a guide that can help systematize the process of addressing these problems. The table below gives a general overview of the guide, summarizing the typical causes and likely solutions to 12 common quality problems in sheet processing.

For each of the 12 problems, the complete guide follows the same systematic problem-solving technique. For starters, this involves accurately identifying and defining the problem. The next step is to sort through the possible causes to determine the root cause of the problem at hand. After that, it is important to develop a plan for solving the problem.

If this sounds too involved, consider the case of one of the most common sheet-quality problems—machine-direction (MD) lines. It is essential to identify the problem accurately because there are actually two types of MD line manifestations: 1) die lines, which have a fixed location along the transverse profile and are continuous; and 2) flow lines, which come and go, changing positions along the transverse profile and varying in intensity and width. Dealing with them involves very different sets of actions.

Die Lines

Die lines could be caused by buildup or blockage in the die, or by damage to the flow surfaces in the die. Die buildup can be cleaned away by running purge material while varying extruder rpm, or it may be necessary to carry out a “split and clean” procedure. But while cleaning is the likeliest solution to die lines, it may be that the propagation of the buildup that caused the lines in the first place can be slowed down by increasing the die-zone temperature setpoints.

If an inspection of the flow surfaces indicates dents or scratches, have the die professionally repolished and the lip edges resharpened.

Flow Lines

Flow lines have different causes than die lines, but again there may be more than one cause. Often it turns out to be too much moisture in the polymer, though sometimes the cause is a mixing problem. To improve mixing, reduce the die gap (which will increase backpressure) and increase the melt-temperature and die-temperature setpoints.

Warpage

Another pair of problems involves warpage, in which the sheet edges curl down or up. Both problems are caused by differential cooling in one of the polishing rolls—one surface of the sheet cooling more than the other—resulting in differential stresses. To address warpage where edges curl down, increase the temperature in the middle roll (number two) of the sheet stack. For warpage where edges curl up, increase the temperature in the bottom roll (number three). Since the die extrudes the sheet into the nip formed by the top roll (number one) and the middle roll and the sheet moves “downstack,” there is almost no contact time between the sheet and the top roll, whose temperature thus has little influence on cooling.

Other Problems

Edge-curl problems are the only sheet quality issues where the causes are readily apparent and the solutions can be achieved by changing only a single process variable. In addressing eight other problems, multiple causes and alternative adjustments are possible:

- Grainy surface or “orange peel.” When the melt is too cold, the sheet surface freezes too soon for the polishing rolls to do an effective job. The likeliest solutions are raising the melt or die temperature, but increasing roll temperature is another possibility. Reducing the die gap also has the effect of increasing melt temperature.

- Rough surface or “shark skin.” The typical culprit here is melt fracture, which can occur at higher output rates and smaller lip gaps. The likeliest remedy is to increase the gap.

- Bubbles, pits, or dimples. These often result from trapped volatiles. If the trapped gas is steam, then the ultimate cause may be moisture in the material. Otherwise, the likeliest remedy is to decrease melt temperature in order to reduce the release of volatiles.

- Wavy edges. Whether irregular or torn, they typically appear if the extrudate is cold toward the sides of the sheet, making it difficult for the material to draw down and neck in smoothly. Other than reducing the melt strength of the raw material, the likeliest remedy is to decrease the draw ratio by reducing the die gap. Other possible adjustments include increasing melt and die temperatures.

- High shrinkage. This often reveals itself during thermoforming when the parts distort excessively, either because too much stress has been put into the sheet or because cooling took place too rapidly, with not enough time for the material to relax. To reduce orientation, the likeliest remedy is a reduction in the die gap and increases in the melt temperature and polishing-roll temperatures.

- Dull or spotty surface. It’s often the result of excessive cooling in the sheet stack and is likeliest to be corrected by increasing polishing-roll temperatures.

- Parabolic lines. They can occur in the center of monolayer sheet when the die zone temperatures are set lower than the melt temperature, causing an override in the central zones of the die, leading to heavy central flow. Alternatively, the melt temperature may be stratified due to inadequate mixing.

- MD thickness variation. Often combined with lines in the transverse direction, this typically results from a surging throughput rate. This unsteady output can be caused by poor mixing, excess moisture, or bridging in the extruder hopper. The likeliest remedy is to reduce the extruder feed-zone temperature.

So-called “preventive troubleshooting” can stop some of these problems from arising in the first place, avoiding costly die damage and downtime. Don’t let the “routine” in routine maintenance fool you. It is essential for protecting your investment in the die and for optimizing sheet quality and productivity.

Routine sheet-die maintenance includes splitting and cleaning the die and replacing end-seal and deckle-seal gaskets, heaters, and worn adjustment components. General instructions for maintenance procedures normally can be found in the die operating manual. EDI recommends developing and adhering to a Preventative Maintenance (PM) schedule based on experience with past extrusion equipment performance.

About the Author

Sam G. Iuliano is technology manager at Extrusion Dies Industries, LLC (EDI), Chippewa Falls, WI. He joined EDI in 1992 as a sales engineer and later served as manager of sales administration and product manager. (715) 726-1201 • extrusiondies.com.

Related Content

How to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreMaximize the Cooling Capacity of Your Extrusion Line

Maximizing output in extrusion requires a thorough understanding of not only the cooling requirements of the extruder but of the extrudate as well.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreOptimizing Barrel Temperatures for Single-Screw Extruders

If barrel temperatures are set correctly and screw design is optimized, the extruder will be operating at peak performance, providing maximum profitability. If not, bad things can happen impacting quality and profitability.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More