At age 65, Mel O’Leary still works 45 to 55 hours a week at the company he co-founded in 1983. “It has been a wild ride. But I still can’t wait to get to my desk in the morning,” That is the sound of a man who has built a profitable and expanding business by doing just the kind of work he wants to do—work that the market demands, but has few other takers. O’Leary is president and CEO of Meredith-Springfield Associates (MSA). His firm fills a need for a technical blow molder willing to tackle difficult jobs that require extensive trial-and-error development—and sometimes modifications to screws, heads and other equipment—even for low-volume or one-off jobs.

“We don’t shy away from a challenge,” O’Leary states. “We like jobs where we really have to work with a process and tooling to make it do things it wasn’t intended for. We learn things that can apply to the rest of the business, even more standard jobs, to make them more reliable, more consistent.” For example, “We do long, narrow parts really well. We have developed the shuttle EBM technology to support the melt strength for such parts.”

He adds, “Something we do well that hardly anyone else does is one-shot jobs with tough challenges for customers that can afford it.” An example was producing clear PVC globes in flame-like spiral shapes for a three-story chandelier commissioned by a casino in Macao. MSA molded 10,000 each of four different exotic globe shapes.

Another example is special medical parts for lab instruments, where the customer will need only 100 of them, ever. “Nobody else in their right mind would do it. This takes a lot of resources that other molders don’t want to sacrifice to oddball jobs. That’s why we get a lot of referrals from other molders. We’re often the customer’s last available option.”

O’Leary’s first guiding principle is “Take care of the customer.” The second is, “Avoid the temptation to take on low-margin, commodity blow molding in favor of value-added opportunities in more technical articles, or applications that offer daunting challenges for others, such as engineering resins, secondary operations like cutting or assembly, or retail-ready packaging.”

MSA has fulfilled the latter commitment with unusual shapes in HDPE, PP, PVC, ABS, nylon, TPE, TPU, and fluoropolymers. More recently, it has pushed the envelope in injection stretch-blow molding (ISBM) of PET and the newly burgeoning opportunity in extrusion blow molded (EBM) PET, or EPET.

PULLED IN BY CUSTOMERS

“I started in my basement,” recalls O’Leary. He was from Springfield, Mass., and his partner was from Meredith, N.H., which was why they named their new firm Meredith-Springfield. Initially, their three-person firm offered training and consulting. It developed VHS-based blow molding education programs, which O’Leary believes were “the first commercial use of video as a training medium in plastics.”

MSA’s consulting work expanded to include supporting new product developments. So, in 1988, O’Leary mortgaged his house and bought a blow molding machine and rented 1600 ft2 to establish a sampling lab. Demand grew and he added more employees and two more machines for sampling and development work.

Then, in the early 1990s, MSA helped Reebok develop an air-filled inner sole of TPU for athletic shoes. “The special screw and head requirements, as well as drying, made every other molder shun taking on the project,” says O’Leary. “Reebok pushed us into limited production to support their launch. We ran 24/7 and shipped four Boeing 747 Freighliners full of inner soles to China. From that experience, we realized that there was a need for a blow molder that could excel at technical molding and exotic resins.”

During the Great Recession years of 2009 to 2012, MSA doubled in sales and size. “Other molders were closing plants, cutting staff, and having trouble servicing clients. We were the last man standing and took on existing work transferred from troubled molders.”

He adds, “We were profitable, had no debt and ample cash. A strong balance sheet made us attractive to banks who had few other qualified borrowers and were offering never-lower financing rates.” In 2009-2010, MSA bought two Aoki one-step ISBM machines to make its first entry into PET markets. “We knew nothing about it, and we relied on support from resin suppliers like DAK and Indorama. We still run some of the same jobs we started with, and the Cpk on them now is the same as before. That’s testimony to the reliability and consistency of Aoki machines.”

MSA’s overall sales have grown 7-12% annually ever since the recession, to the current level around $15 million. “We bought three machines in the last 19 months—one Bekum EBM and two Aoki’s—and all are sold out. With 21 new mold programs in the last half of 2018, we’re nearly filled to capacity on a five-day week. We’re negotiating our next machine purchases and upgrading our central process-water and compressed-air systems and piping to be ready for new machines to be delivered later in the year.”

Today, MSA employs around 100 people—about a third of them 10-15 year veterans—at a 90,000 ft2 plant in Ludlow, Mass. The facility currently houses six double-sided continuous-extrusion shuttle machines from Bekum (H-155’s) and Battenfeld Fischer (lovingly rebuilt FHB 15-2 models). One of those machines is now dedicated to EPET, and more will be in the future. There are also five Aoki ISBM machines (350 and 500 models), and provisions are being made to add three more in the near future.

One of the largest Aoki machines has double-row tooling and 16 cavities, producing PET spice bottles. The newest machine is an AL-500LL-50S, the first in North America. It’s one of a new series, introduced at NPE2018 (see August feature). O’Leary says this machine runs at half the cycle time of earlier ones, so around half as much tooling is required. “This makes it less expensive for the same output in quantities less than 10 million units,” says O’Leary. “It needs half as much tooling for that output, so that ISBM tooling cost can now approach that of EBM. It removes the barrier to the customer getting exactly the neck finish desired.” MSA is currently running personal-care bottles on the new machine in three cavities on a 10-sec cycle.

MSA’s two largest markets are food packaging and personal care/HIC (household and industrial chemical) containers, each approximately 20% of the firm’s business. Medical reagents account for about 10%; and a mix of consumer and industrial products (such as lawn and garden, ice packs, and water-bottle cases) is another 30%.

“When we consider a potential job, I ask, does it fit our equipment? Do we have the expertise for it? I don’t care what the market is—except for only two. We avoid cosmetics and automotive work because they require another whole level of management.”

CHALLENGING PARTS

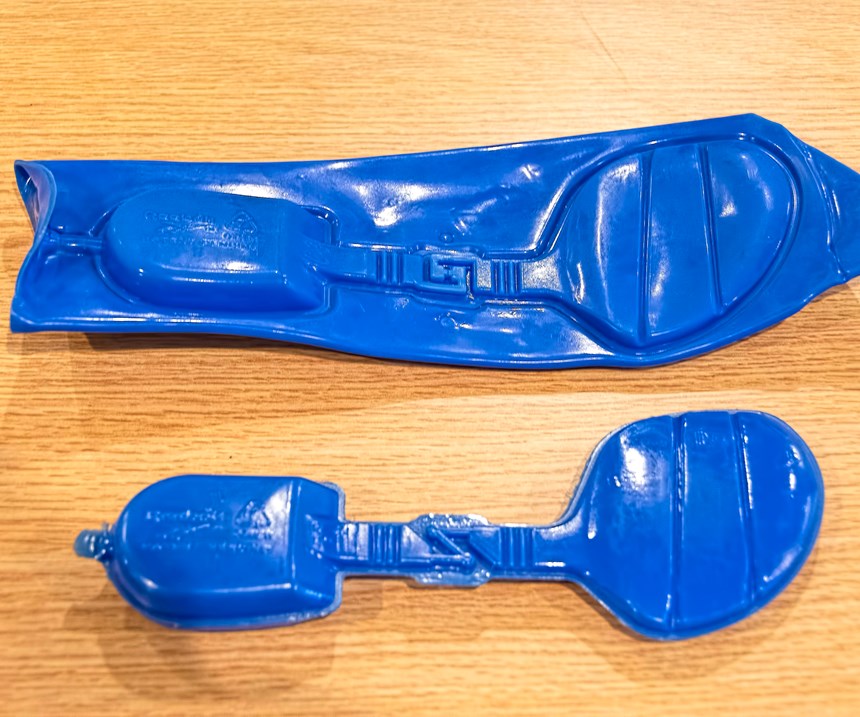

Examples of long, thin parts made by MSA include EBM deck balusters of PVC, thick-walled parts imitating highly milled shapes (see photo). MSA still runs a lot of PVC, including devotional candle holders produced at a rate of 10 million a year.

One of the firm’s most challenging EBM applications is a small lab reagent reservoir of HDPE. “This one really pushed our capabilities,” says O’Leary, pointing out its two calibrated neck openings, facing at different angles roughly 180° apart, at opposite ends of the part. What’s more, the blow ratio is at 90° to the parting line. “Nine of 10 blow molders would say it can’t be done,” O’Leary observes. Another unusual HDPE part is a two-chambered part with two necks and a hollow handle. The largest EBM part MSA has molded measured 36 in. tall × 12 in. wide × 8 in. deep.

Although the Reebok mid-sole is no longer in production, MSA blow molds TPU flexible boots and vapor-containment collars for gas-pump dispensing nozzles. Another unusual resin run by MSA is Eastman’s Tritan proprietary copolyester, which is used for a gallon handleware jug for photographic chemicals.

MSA has a few customers for multilayer EBM. One application is a three-layer HDPE container for a surgical adhesive. The inner layer is virgin resin with no additives that could react with the adhesive. The outer layer contains color and UV blocker, while the middle layer is regrind. MSA can also make containers with view stripes.

PET accounts for about half of the firm’s business, the majority of that in ISBM. An example of unusual work MSA is doing in this field is a line of bar ware that has a smooth, round lip. These parts are molded with a dome that is subsequently trimmed off. Then, the drink glasses move on a conveyor from the ISBM machine and trimmer to a special lip-former built by MSA that applies heat and pressure to the rim of each cup, folding it over and welding into a smooth bead.

EPET PIONEER

MSA’s experience in the emerging field of EPET (see January Close-Up) goes back at least two decades. O’Leary recalls, “Twenty or 25 years ago, Eastman, DuPont and others promoted a version of EPET, but it was a finicky resin and very expensive, so it faded away.

“Then, 10 years ago, it re-emerged. We did some of the initial sampling for Eastman and DAK. It was a major commitment for us. We accumulated a lot of regrind before we got it figured out. We participated in the development of special screws. We worked with W. Muller on multi-parison head design for EPET.” MSA runs up to three parisons and six cavities; O’Leary thinks others run only one or two parisons. It took multiple iterations of both screw and head designs to achieve success.

“The machine also needs tight temperature control and high-temperature barrel heaters. And we had to learn about material handling for EPET—drying, blending and recrystallizing regrind.” Drying, in particular, is unfamiliar to many extrusion blow molders. “EPET material has to be bone dry (-45 F dewpoint) or it loses melt strength. And you can’t use the regrind if it loses IV due to moisture degradation.” MSA uses up to 65% regrind in some EPET products.

“I remember when extrusion blow molding of PVC came in during the 1970s—it was the same sort of learning curve,” recalls O’Leary. His conclusion: “We went through a lot of pain to get where we are now. But the resins are much better now, and the special equipment designs have been worked out. But it’s still not for the faint of heart. It’s not like molding HDPE, where anything goes. You need strict process control. But given the opportunities in EPET, I’m still surprised that more mid-sized processors are not trying it.”

O’Leary explains, “We regard EPET as a lower-cost stepping stone to ISBM for unique bottles with unusual neck finishes or very tough blow ratios. It’s a way for an application to get established at lower tooling cost than for ISBM. It’s an option for a brand owner or an independent entrepreneur who doesn’t know how big the demand for the product will ultimately be, but he needs a clear bottle and a handle or a large blow ratio or a special neck—all things that don’t lend themselves to ISBM.”

If the sales volume eventually justifies a step up to ISBM, he notes, the price per container actually goes down. That’s because conventional PET bottle resin (0.8 IV) costs 20-30% less than EPET at 1.3 IV. What’s more, ISBM has lower conversion cost, owing to lower labor input and less scrap, according to O’Leary.

EPET is about 12% of MSA’s business now, with 15 or 16 steady jobs. Committed to non-commodity work, MSA has not pursued the successful opening for EPET in orange-juice bottles. Rather, MSA has developed unusual and innovative applications in food, personal-care, and medical packaging, such as these examples:

• A 21-in.-long container for a special medical application. It has a 28-mm neck opening and a round profile, except for one flat side, so it won’t roll on a counter or bench.

• A 1.5-liter, wide-mouth jar for storing communion wafers. The 4-in. neck opening is achieved by molding a dome and removing it by spin-trimming. (O’Leary is holding the jar with dome attached on the front cover.)

• A maple syrup jar with a heavy wall to mimic glass. What’s unusual is that it is filled at 185 F, above the glass-transition temperature (Tg) of the resin—“something that shouldn’t be possible,” O’Leary notes.

• EPET containers with unusually shaped calibrated necks, such as an oval or a triangular pour spout (see photo).

(Read what Mel O’Leary says about automation and information management at MSA.)

Related Content

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreFirst Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreBreaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More