Web Connectivity: the ‘Missing Link’ To Molding Machines & Auxiliaries

Cover story

Web services technology is being utilized today by many molding companies to enhance their molding operations performance, expand uptime, and obtain supplier support in shorter time for very low cost.

Web services technology is being utilized today by many molding companies to enhance their molding operations performance, expand uptime, and obtain supplier support in shorter time for very low cost.

Consider the equipment issues faced by a typical technician—let’s call him “Joe”—in most molding plants. On Wednesday morning, Joe tries to troubleshoot and fix a problem in molding cell #32 by himself. Before the last recession, Joe used to have a 50% larger maintenance staff than he has today. Joe used to put one of his subordinates on a production-cell problem, but now he must fix it himself, even though he has a list of other priorities, including an urgent need for a mold change on press 46.

Later that afternoon, Joe finally has a moment to call his equipment vendor for some guidance on the cell #32 issue. He gets some suggestions from the vendor and runs back out to the cell and tries them out.

Joe then calls the vendor back and has a second exchange of ideas and heads back out to the cell for more trial-and-error problem solving. During this process, Joe is multi-tasking two other shop-floor crises, so this process takes four hours and spills over into the next morning.

On the third call to his vendor, Joe asks how soon he could get a service technician dispatched to his plant for help. The vendor says that since it’s now Thursday, perhaps they could have someone in Joe’s plant by early afternoon Monday.

The end result: Cell #32 is down for around five days until the vendor’s service technician can get there, resolve the issue, and Joe can have the cell running well again. This story has a few variations, like the vendor’s technician discovering that the cell requires replacement parts to work through the issue. That would mean more delays, extends the service call, and adds costs.

The national average number of phone calls to resolve a plant issue is 3.5 calls.

A BETTER WAY

Now let’s replay the same situation, this time with a web-based technology some molders use today:

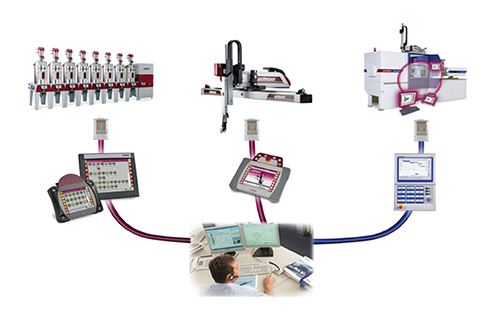

Joe tries the first couple of calls and asks his vendor to use the web-based connection tool. The vendor reviews the machine status immediately, as if its technician was on Joe’s plant floor. The web connection tool allows the vendor to see Joe’s Cell #32 machine program, error logs, command log, and system reports and to check all machine conditions remotely. Any screen display on the machine’s controller can be viewed remotely via the web.

A replacement part is deemed prudent to test and the vendor overnights the part. The next day, Joe puts the part in the machine and succeeds in bringing the cell back on line before the weekend. Joe’s company did not have to pay for a service technician’s travel or hourly labor rate and did not have to lose several days of downtime.

While the vendor was examining the machine online, it also was able to see how Joe could modify the process and take another 1.5 sec off the cycle time, effectively increasing the cell output by 16%.

FOR AUXILIARIES, TOO

Web-based service for injection molding machines and auxiliary equipment has been proven to decrease delays and service costs while it has also proven to be very secure to plants’ security and intellectual property. For connection, today’s web-based systems can use Ethernet Cat 5 cable hard-wired hookup, WiFi-enabled networking, a cellular connection (even tether off a cell phone), or a PC with internet to link their equipment to their supplier for tech support.

Wittmann Battenfeld, for example, offers a new Web Connect box that can work by itself with a robot to ping the vendor’s service line for immediate online diagnostics that include oscilloscope signals to optimize cycle times. This does not use the customer’s server or intranet.

Web-based service is being used today not just for molding machines, but also central water systems, central material-handling systems, and robots and automation cells. Nowadays, web-based connectivity can provide remote diagnostics and troubleshooting for individual auxiliaries such as mold-temperature controllers, dryers, loaders, blenders, granulators, hot-runner controls, and more.

Using smart-phone and tablet apps, users can obtain email alerts from a down cell. For example, on a weekend, if a down cell does not resume full automatic cycle after 55 min, an email goes out to the weekend shift plant manager and a copy to the weekday manufacturing director.

Via the web, a molder can remotely monitor conditions of a plant system or a particular cell from anywhere. This ability is safe and secure—for use only by approved customers, employees, and hired experts.

Molding process or maintenance experts can help out a colleague and advise on equipment issues without visting the plant. This is especially useful when one plant has expertise or experience with a problem that can help out a sister plant within the company.

A web camera can be placed on the molding cell to show its operation for observation by remote troubleshooters. Voice communication can be established via the internet (VoIP), eliminating telephone charges during online support sessions.

If a problem is determined to be a software issue, the vendor can make a fast, secure upload of software upgrades from tech support directly to the machine controller while connected to the customer. Software fixes can thus be sent and tested out in far shorter time and with much lower cost then the industry is used to.

Using a tablet computer app, one user can modify a dozen robots’ password security levels without walking around the plant to visit each robot in person.

Molders have used web-based support to enhance their employee training. In one real-life case, the equipment vendor traced an issue to an electrical panel and drilled down to the electrical schematics and circled, on the customer’s control screen, where to look for the jumper.

Another user decided to make small parameter changes to his mezzanine dryers without having to climb up there on a hot summer’s day. He could see an error on one machine-mounted material hopper loader on his iPhone while he was traveling away from his plant.

Another molder used the diagnostics help from his vendor and then, while still online, sent the replacement parts order to his vendor, while still at the machine, in real time, in minutes.

Related Content

Automation in Winding, Coiling and Cutting for Reduced Labor and Increased Safety and Consistency

Reel Power will demonstrate how its automatic winding system works in concert with extrusion and automated pick and place.

Read MoreEngel Teases Generative AI Assistant at Digital Days Event

The Austrian maker of injection molding machines and automation introduced a prototype large-language model assistant for its customers: Engel GPT.

Read MoreSmart Systems Illuminate Material Recovery for Enhanced Plastics Recycling

Data collection and machine learning can give MRF operators and brand owners an enhanced view of the fate of recyclable materials.

Read MoreLSR Advances in Dispensing, Tooling and Automation

At Fakuma 2023, Sumitomo (SHI) Demag’s LSR injection molding machines showcased advances from itself and partners Reinhardt-Technik, Rico and Sepro.

Read MoreRead Next

Web-Enabled Auxiliaries Save Time And Shoe-Leather in Molding Plant

Internet connectivity for plastics equipment is a relatively new and growing technology. Here’s how it works at Samtec.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More