Web-Enabled Auxiliaries Save Time And Shoe-Leather in Molding Plant

Close-Up: Auxiliary Equipment

Internet connectivity for plastics equipment is a relatively new and growing technology. Here’s how it works at Samtec.

Hoofing it around a 150,000 ft2 plant answering alarms and attending to job changeovers on 15 injection presses can be an energetic workout for the lone material handler on day shift at Samtec Inc. in New Albany, Ind. But for the last 18 months, that job has proceeded at a less strenuous pace, thanks to remote monitoring and control of web-enabled materials-handling auxiliaries at the plant.

Internet connectivity for plastics equipment is a relatively new and growing technology (see also the cover story of this issue). Here’s how it works at Samtec.

The firm is a $500-million manufacturer of electronic connectors and cable systems with seven plants in six countries. Besides injection molding, it performs wire extrusion, metal stamping, electroplating, automated assembly, and even thermoforming of packages for its products. It started molding about four years ago, and as that operation grew, the firm built a new dedicated plant at its New Albany headquarters.

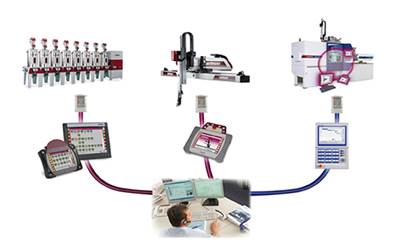

Wes Luallen, now in the Production Engineering Dept., was lead technician for the installation of the web-connectivity system for the new plant a year and a half ago. That system networks 15 hopper loaders on the presses, plus four blenders, one deduster, and loaders on 11 dryers—all from The Conair Group, Cranberry Township, Pa. These units have hard-wired links to a Conair FLX central control station that uplinks wirelessly to the internet. As a result, says Luallen, “We can see what’s going on with any piece of Conair equipment on an Apple iPad, iPhone, or iPod Touch. In fact, we have an iPad at each molding press, for which we build our own apps.”

This step up to wireless remote monitoring and control grew out of Samtec’s two-year experience with its Nissei molding presses that have similar wireless remote capability. “I can control any function with my iPhone,” says Luallen.

LESS RUNNING AROUND

Deploying web connectivity for the Conair auxiliaries at Samtec involved mainly an upgrade to the central FLX controller, at very modest cost. As a result, the material handler can attend to any of the loaders, blenders, etc. without having to run over to the machine or to the FLX control station, which could be 200 ft away from where he is standing.

“It’s such a time-saver,” says Luallen. "It eliminates 90% of the steps he’d have to make walking around during the day. He can be anywhere in the plant and turn any piece of equipment on or off, such as at the end of a job run. He can see the control screens and change any setting there, such as loader dump times. We have mezzanines, and he no longer needs to climb up there to look at the equipment.

“It’s great for troubleshooting,” Luallen continues. “He can energize a loader and hear whether the valves are switching on and off as they should. If we’re getting wet material into the hoppers, he can increase the time for purging the lines.”

As a result of this experience, Luallen would recommend web-connected equipment to any molder: “It’s a very useful tool. I don’t know how we could go back to the old way of having to be on the spot to check things."

Related Content

Conair Names New Head of Customer Care

Jared Helfrich to direct the efforts of the machine builder’s growing customer care group, combining its existing parts and service and repair organization with a new range of fast-growing customer services.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreProcessors: Gear Up to Handle More Regrind

Plastics auxiliary and primary processing equipment was optimized for running pellets; here’s how you can adjust to the bulk density differences of flake and regrind in drying, conveying, mixing, feeding and processing.

Read MoreCut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

Read MoreRead Next

Web Connectivity: the ‘Missing Link’ To Molding Machines & Auxiliaries

Web services technology is being utilized today by many molding companies to enhance their molding operations performance, expand uptime, and obtain supplier support in shorter time for very low cost.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More