What Toolroom Maintenance Supervisors Need to Know-Part II

September’s “Mold Shop” column presented an overview of a mold maintenance supervisor’s need-to-know priorities.

September’s “Mold Shop” column presented an overview of a mold maintenance supervisor’s need-to-know priorities. Here is more detailed discussion of mold maintenance and production scheduling.

When a mold maintenance supervisor walks through the door of his plant, chances are he will be greeted by someone in obvious stress, noted by the bulging veins and eyeballs. Typically this stress will concern a mold that is supposed to be running but is not—the reason being usually unknown. When this happens, the urgency of the breakdown will be conveyed during an animated walk to unlock his office. From there a trip to the toolroom or molding floor will ensue to see the problem first hand to try and figure out how the mold can be patched up and returned to the front line until it breaks down again.

So the supervisor takes corrective measures to put the fire out—or at least makes a plan to do so. And as one fire fades, another one smolders. It’s the nature of the job. It comes with the territory. Whatever. But is there a better way?

Even though a supervisor wears the firefighter hat during many hours of his or her day, there will still be time to be proactive in this job. So let’s look at what the supervisor is doing between fires.

SCHEDULING WORKS

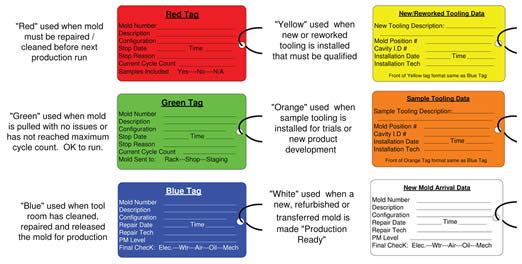

The next dilemma usually involves whether or not a mold that is scheduled to run is Blue-Tagged (production ready) when the set-up technicians head to the rack to retrieve it. The obvious goal is to avoid idle time for the press while processing personnel wait for the toolroom to get a mold ready. That requires accurate scheduling of mold PM’s (preventive maintenance) or C/R’s (clean and repair). And accurate scheduling depends on a few critical factors:

•The company’s ability to forecast sales helps the toolroom supervisor know what molds or products will be needed in the next week, or better yet, the next month. This might be a difficult or impossible challenge in some custom molding plants, but many captive molders could work up a list of molds or products that are next in line for production—and yet many of them don’t do it.

Sometimes past experience will serve as a guide to which molds need to always be ready. Need for other molds can sneak up on you at the wrong time and completely disrupt a repair—or worse—production schedule. When that happens, malfunctioning molds don’t get fixed—they get patched—because there is no time for the appropriate repairs.

- A toolroom supervisor obviously needs adequate headcount in the shop to get the job done. American companies continue to go lean to the bone, especially in maintenance, by not replacing personnel lost through layoffs or retirement, or not hiring additional help when more molds are acquired. If headcount is too lean, the only work that gets done is chasing after breakdowns.

- Necessary tooling must be available to make repairs or changeovers. Too often, molds get pulled for maintenance when there is no replacement tooling in-house to make the repairs. More wasted time. To minimize such waste, maintain an accurate inventory count and keep items in stock based on the history of past defects. (A rule of thumb is to keep replacement inventory of 25% of mold tooling on hand. But that may not be possible for every shop.)

- A mold maintenance supervisor can do his/her job effectively only if new problems or surprises are not continually popping up during disassembly, corrective action, cleaning, reassembly, and final check. If mold condition and past defects are not diligently tracked, they will result in extended downtime while you wait for the right tooling, person, or the time to make necessary repairs. Then production has to scramble—and change its schedules—to better utilize a down press.

Mold maintenance supervisors working for companies that engage in the short-run JIT philosophy (run two to four hours, then pull the mold or change over tooling) have a much tougher challenge than those who have mostly long runs and the option to pull molds based upon cycle times or production hours. With short runs, it is common to run and pull a mold without the toolroom ever knowing it happened. Then one day, the mold will develop a problem and the supervisor or repair tech will scramble to discover the sequence of events since it was last in the shop. This must be done order to troubleshoot effectively and ascertain the root cause.

Some companies perform as many as 20 changeovers per shift. If left undocumented, these can monopolize shop hours and do not promote proactive maintenance. But there are steps that can be implemented to keep up with any MPP (mold pull pace).

AN OLD BUT GOOD IDEA

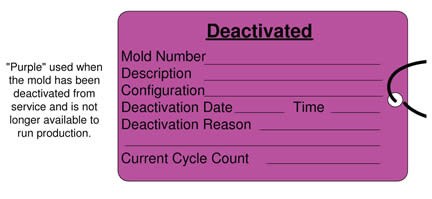

A critical part of efficient toolroom work scheduling is the ability to quickly and accurately understand a mold’s current production condition. An old industry method (but still best practice) of using color-coded tags on molds (see sidebar) was popular for awhile, and then faded with advent of inventory control modules in ERP (enterprise resource planning) and CMMS (computerized maintenance management) systems. Physically tagging molds and entering mold locations and status into a computer database seemed redundant, so tagging was neglected.

This works only marginally well. Although computers can give more people access to mold-status information, if someone forgets to electronically update the information, molds get set that still need cleaning, repair, or changeover. So the mold is pulled again. One mistake like this can waste more time through investigation than would be spent physically applying tags to molds throughout a year. So the practice of mold tagging still has merit if a few steps are taken to streamline the process.

To make this system easier, tags of the appropriate color should be placed in close proximity to where they are used. That is, red and green tags should be kept on the process floor and everything else in the toolroom. There are several ways to affix tags to the mold, with most popular being wire or nylon ties. Tags can be made in many shapes and sizes, using plastic or paper—the choice should be determined by the molds’ working environment.

The format of the tags should ask for specific information, rather than simply giving space for a freehand “journal entry” of (usually) incomplete or illegible data (see accompanying illustration for a model format). How much data is required on the tags will depend on how much data is available in the electronic system and how much redundancy one is willing to accept in filling out a tag. Some companies do not write any data at all on the tags, using their color only as a visual alert to investigate the database for current status and maintenance issues. That’s better than nothing, but it still forces you to go to a PC terminal to get usable info.

If molds are stored in typical racks or on pallets on the floor, it is handy to be able to walk up to one and read the data on the tag, as opposed to logging into a computer to see why the tag is anything but Blue. A typical rack normally does not have molds positioned by tag color, so it is handy, to say the least, for the tags to be accessible from the exposed side of the mold for ready reference.

Tags tend to give a quick and accurate indication of a mold’s status. It would be unusual for a tool-repair tech to blue-tag a mold and leave a bright red one still hanging from it.

And tags prevent mistakes. If a mold setter sees a red tag hanging from a mold that is stored 15 feet in the air, the setter will check the mold status on the computer before even removing the mold from the rack, let alone setting it in a press.

For those short orders, a mold that is run, pulled, and put back on the rack without going through the toolroom should have several green tags hanging from it, or one updated tag that documents all the runs.

Don’t go overboard with tagging and try to make it what it will never be—an accurate documentation system. Some shops try to use the tagging system to manually document run and repair problems and corrective actions. This is not an efficient method because too much tag data inherits the same problems as any manual entry system. Ambiguous, unformatted, illegible, incomplete, and inaccurate notations tend to proliferate.

Electronic tracking will never lose favor, because data on current mold status will always be important to many individuals and departments that need it to do their jobs. For the toolroom supervisor, it is helpful to be able to create an electronic report that displays the status of all molds in your fleet, both for scheduling purposes and to keep track of your backlog of work.

About The Author

Steven Johnson worked as a toolmaker for 26 years, rebuilding and repairing multicavity molds for Calmar Inc. and then as mold-maintenance engineer for Hospira Inc., a medical device manufacturer. Today, he is the maintenance systems manager for Progressive Components and has his own business, MoldTrax in Ashland, Ohio, which designs and sells software for managing mold maintenance (www.moldtrax.com). He can be reached at steve@moldtrax.com or (419) 289-0281.

Related Content

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreHow to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreRead Next

Why Mold-Maintenance Data Is Essential for Processing Technicians

When I was in the Navy, many different trades such as hydraulics, electrical, airframes, armament, and jet-engine mechanics worked side by side to get planes into the air, through their scheduled missions, returned to base, and turned around to do it all over again.

Read MoreWhat Toolroom Maintenance Supervisors Need to Know

Those in charge of keeping molds reliable and production-ready normally start their day in the same manner—wondering what broke down since they last walked out the door—and hoping they have the resources to get it going again.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More