When Do-It-Yourself Robot Tooling Is Not the Way to Go

Many injection molders have met their parts-handling needs by building their own robot end-of-arm-tooling (EOAT) with off-the-shelf modular components.

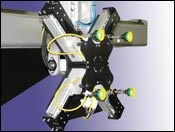

Many injection molders have met their parts-handling needs by building their own robot end-of-arm-tooling (EOAT) with off-the-shelf modular components. But this approach reaches its limits when dealing with complex parts. Tough-to-handle parts require EOAT systems with more sophisticated multi-function capabilities, but molders commonly fail to grasp how the part actually needs to be removed from the mold until the tool is run for the first time.

Ironically, this failure may be due to the very success molders have had with do-it-yourself EOAT systems using modular components in the last 10 years. Molders have acquired confidence in their understanding of how to configure simpler EOAT with standard components like vacuum cups, frame profiles, frame connectors, quick-change chucks, pneumatic connectors, mounting clamps, gripper mounting arms, gripper fingers, part/sprue pliers, sprue cutters, cylinders, and control systems.

But assuming that modular components always can fill the bill can be a costly mistake when it comes to more complex applications. So it is important to know when your molding application needs the special benefits that are available with a custom-engineered tool.

When To Go Custom

Molding operations that typically benefit from custom EOAT have one or more of these issues:

- Parts that stick or are otherwise difficult to remove.

- Parts that need to be rotated.

- Parts that must be removed in a specific direction.

- Part weight or bulkiness that makes it awkward to handle.

- Class-A surfaces that need protection from damage.

- Applications involving insert molding and overmolding.

- Multiple cavities.

- Jobs with secondary operations like degating, assembly, or packing.

- Parts where vacuum cups cannot be used.

- Jobs that require a stronger tool but also lighter weight.

- Pulling different sized items with just one EOAT.

Custom-built EOAT can combine several functions that can operate simultaneously or in sequence, which a standard EOAT cannot do. An example is a custom system designed to pick a molded part and then place steel inserts in the mold for the next part. The robot and EOAT first pick the inserts from a rotary table, then demold the finished part, then index down and insert the steel inserts into the mold in three different paths that are not parallel to each other. (Do-it-yourself tooling might suffice if the inserts were loaded in a straight line.) This tool eliminated excessive cycle time from having an operator manually place 12 inserts in the mold and remove the molded part. It also reduced workers’ compensation issues associated with an operator pulling the very heavy and hot part from the mold.

A custom-engineered tool not only offers more features, it can be—and usually is—less expensive than the costs incurred from production downtime or requiring manual parts removal and/or secondary operations. Sometimes a combination of off-the-shelf and custom components are used to make a tool, and sometimes the entire tool is custom fabricated. Custom tools are tested before they go into production, adding another level of confidence. However, molders should note that a custom tool takes more time to build than an off-the-shelf kit.

Other Considerations

Molders should consider a programmable EOAT system to eliminate dealing with multiple end-of-arm tools and tool changers. It can be built from modular or custom components, depending on the application. For example, if four separate parts are picked up at one time, the programmable EOAT will allow for sequencing and re-positioning the parts before releasing them.

Sensors and wiring are another area that deserves attention for proper EOAT operation. It is common for a custom tool to have multiple sensors, but not an off-the-shelf do-it-yourself system. Vision, pressure, or position sensors confirm that a part is present or communicate that something has happened, such as gripper closing or placement of inserts. Sensors can be used for tool identification and can detect whether you have the correct EOAT for the installed mold and or tooling plate. Changing sensors—often a problem with custom-built tooling—can be made easier by using convenient connectors.

On the wiring side, molders should be aware that custom-engineered tools usually come with a logic junction box, which provides built-in protection to minimize damage when changing sensor wiring. Off-the-shelf tools do not usually use a junction box, but it ensures that if wiring needs to be changed, it can easily be switched from PNP to NPN format or vice versa with a simple switch of the jumpers. This also means a custom tool can easily be moved from one robot to another.

About The Author

Tim Thatcher is production manager at SAS Automation in Xenia, Ohio. Thatcher has been with SAS since 1998 and is in charge of production of all modular components, custom tooling, degating equipment, custom machinery, and robotic automation cells. He can be reached at (888) SAS-EOAT.

Related Content

New Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreScaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More