Why Blum Went All Tiebarless

It Takes a Small Machine to Carry an Oversized Mold

One of the first adopters of tiebarless injection machines a quarter-century ago uses them exclusively, both here and in Europe. One reason is their ability to handle oversized molds with awkward projections on smaller presses.

For both Julius Blum GmbH and Engel Austria GmbH, it has been more than a quarter century of success with tiebarless injection presses. Engel (U.S. office in York, Pa.) pioneered the commercialization of this machine style 26 years ago and has sold more than 60,000 of these units to 10,000 customers worldwide.

One of its first tiebarless customers was Blum, a captive molder of hardware and fittings for cabinets and drawers in Voralberg, Austria. Blum has since standardized on Engel tiebarless presses for all its in-house molding in Austria and at its Blum, Inc. facility in Lowesville, N.C. Since 2000, that plant has installed 20 tiebarless Engel victory hydraulic and e-victory hybrid machines from 90 to 200 tons. “We are convinced we can master our challenges in a particularly economical way with this machine design,” says Christian Platzl, manufacturing engineering manager at Blum, Inc.

He sees the greatest advantage of tiebarless technology in fast mold setup. The U.S. plant makes at least six mold changes a week. The freely accessible mold area saves a lot of time. With no tiebars in the way, molds can be mounted directly from the side without having to remove core-pulls, and water-cooling lines can even be connected in advance. Maintenance technician Chris McCandless points out another advantage in ergonomics: “The clamping claws are easily accessible. We don’t need to stoop down to reach between the tiebars to set up the mold.”

LARGE MOLDS ON SMALL MACHINES

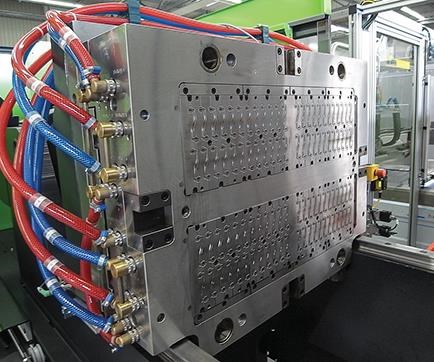

Blum designs and builds about half its molds at its Austrian headquarters. Very early on, the firm began to optimize its molds specifically for use in the tiebarless presses. Thus, some molds are taller vertically so that they protrude down into the ejection chute, while mechanical functions like servomotors for unscrewing threaded parts are often mounted so that they protrude beyond the left and right edges of the platens. “Only the cavities need to be located within the platen face,” explains Bill Pollard of Engel distributor ABC Lemke Plastics Machinery, based in Charlottesville, Va. The accompanying photos illustrate examples of how overhung molds can be carried easily by tiebarless clamps.

Thanks to the barrier-free mold area, very large molds can be mounted on relatively small presses. This benefits the molder because unit costs drop when machine size can be selected according to the actual clamp-force requirements rather than the mold size. Blum has realized this advantage increasingly as it has moved toward higher-cavitation molds—up to 128 cavities currently.

PLATEN PARALLELISM FOR PRECISION PARTS

Blum molds mostly small parts that are assembled before shipping. So that drawers, for example, glide open and closed smoothly, the components must fit together perfectly. Even microscopic surface imperfections or the slightest deviations in dimensions could impede functionality or lead to failure.

Thus Blum requires perfect platen parallelism, which it confirms with annual checks. Thanks to Engel’s design, the moving platen follows the mold precisely while clamping force is being applied, according to Pollard. He notes that the transferred force is very evenly distributed across the entire mold platen, resulting in extremely consistent wall thicknesses.

The most recent additions to the North Carolina plant were two hydraulic and two hybrid Engel victory machines. All four have servohydraulic “ecodrive,” which reportedly cuts energy consumption of hydraulic drives by up to 70%. For example, if no machine movements take place during the cooling phase, the motors stop and consume no energy. Less heating of the hydraulic oil results, so less oil cooling is needed.

That is a welcome feature in summer weather at Lowesville. “Cooling the production hall in summer is often quite a challenge,” says Blum supply-chain specialist Bill Gayer. “Production equipment that produces less heat is more than welcome.”

Related Content

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreTederic Promotes High Technology, Broader Market Presence

Four cells are running in its booth including a 1,300-ton multimaterial system highlighting its 2K capabilities.

Read MoreScaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

Read MoreU.S. Debut for Slimmed Down Electric Machine

NPE2024: Arburg’s debut of the 310-ton Allrounder 720 E Golden Electric extends the tonnage range of the electric series and marks the first global press premiere outside of Germany.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More