Wittmann Battenfeld Celebrates 10th Anniversary with Launch of New Machines

Celebrating 10 years since the acquisition of the Battenfeld brand with new vertical presses, all-electric machines for high-speed packaging, and additional large-press sizes.

Last month, Wittmann Battenfeld (U.S. office in Torrington, Conn.) celebrated the 10th anniversary of Wittmann’s acquisition of the Battenfeld injection machine business at the company’s headquarters in Kottingbrunn, Austria. A highlight of the event was the announcement of a new machine line and expansions of several other press series.

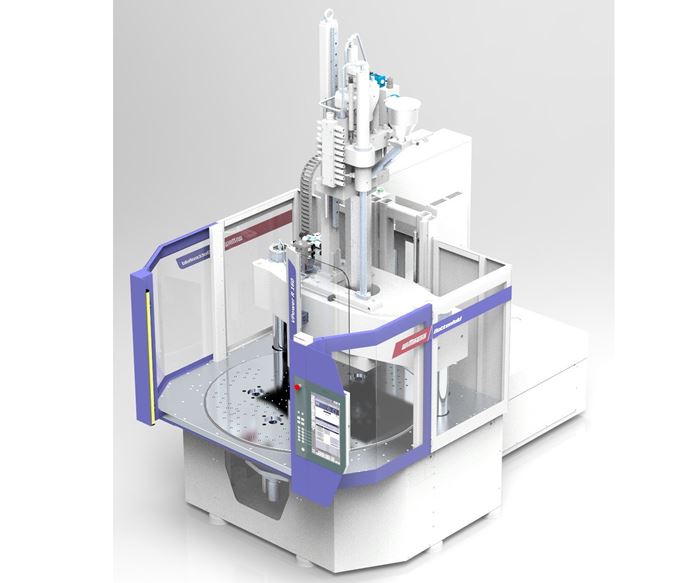

• A prototype of the new servohydraulic VPower vertical press line was displayed in a 160-metric-ton version. Other models of 120, 200, 250, and 300 m.t. are planned. Key features include a “substantially reduced” footprint; low, ergonomic working height (less than 1 meter); servo-electric rotary table; easy conversion of the injection unit from vertical to horizontal, and open design for easy integration of automation systems. Elimination of the middle tiebar that was on previous units leaves space for central supply of media or a rotary union. The first machines are due to go on sale this fall, in time for the Fakuma 2018 show in Germany.

• The company is supplementing its EcoPower Xpress 400 with a new 500-m.t. model. These are both high-speed, all-electric machines tailored for packaging and thin wall molding. It’s available now. Models of 160, 210, and 300 m.t. will be available later this year.

• A larger, 400-m.t. model of the SmartPower servohydraulic line will be available this year. Current sizes are 25 to 350 m.t.

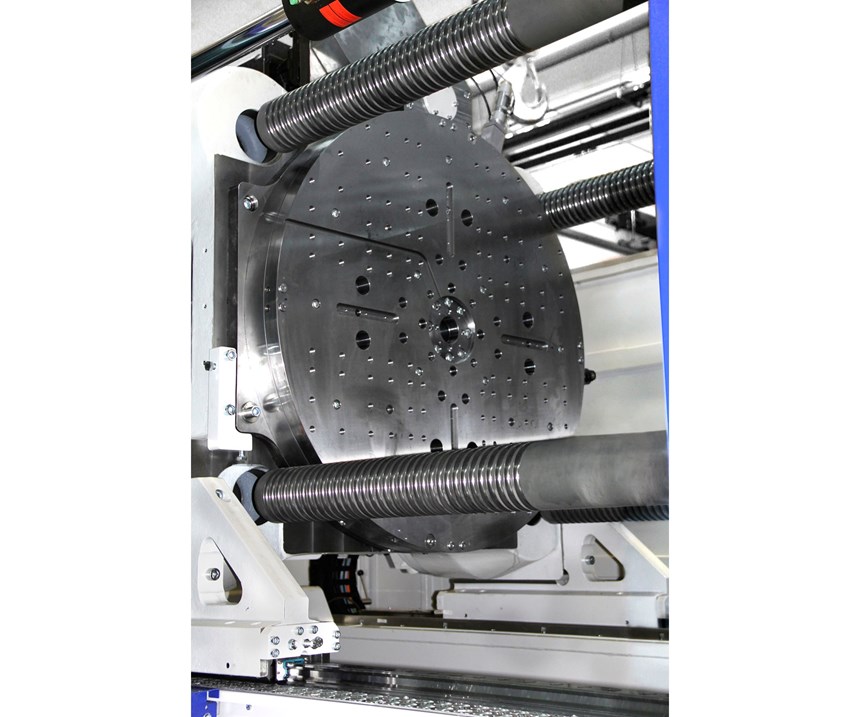

• The company is building larger models of its MacroPower hydraulic two-platen presses, including MacroPower XL 1100 and 1600 units and the largest in the series, MacroPower 2000, the first of which was completed in January. The first MacroPower 2000 two-component version, with a 2000-mm-diam., servo-driven rotary table, was shown at the anniversary celebration.

Related Content

-

Molder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

-

Coinjection Technology Showcases Recycled Material Containment

At Fakuma, an all-electric PXZ Multinject machine sandwiches a black core made of mechanically recycled PC/ABS within an outer layer made of chemically recycled ABS.

-

Electric Injection Molding Machine Line Expands

Boy will debut three new models in its Electric series of machines, which feature a redesigned and more compact drive and inverter technology.