Articles

How to Mold This ‘Impossible’ Part

New low-pressure injection molding process “breaks the rules” and solves difficult molding problems.

Read MoreClariant Examines the Role of Color in a 'Circular Economy'

Top Clariant pigment expert sums up color compatibility with the plastics circular economy with a focus on packaging.

Read MorePlastics Technology’s Most Popular Articles in July

These articles published in July generated the most interest from our readers. Thermally conductive plastics, residual molded-in stress, cooling feed throats, monitoring mold temperature when running PC and more.

Read MoreIn-Depth Guide on How to Measure Color in Plastics

In the plastics industry, standardizing the color process can be both difficult to understand and even harder to implement. Here are basic tips for improving color measurement and establishing color consistency.

Read MoreHow Graham Packaging is Helping to Create a Circular Economy for Plastic Packaging

Graham Packaging’s Tracee Reeves talks with Plastics Technology about ways the company is working to encourage recycling, improve product recyclability and increase offerings with recycled content.

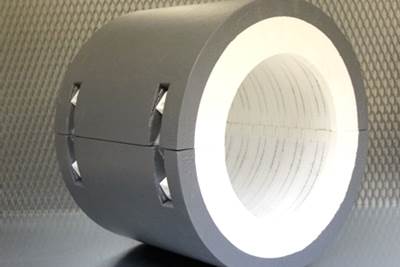

Read MoreFaster Barrel Heating Makes for Speedier Startups

Swapping out OEM ceramic heater bands with special insulated TCS (Thermal Control Solution) heater bands saves California molder time and energy.

Read MoreUnderstanding—and Using—Decompression to Your Advantage

Decompression—aka suckback—is a very important setting on an injection molding machine. On today’s machines, molders typically get the option to set decompression before and after screw rotation/recovery. Are they using this feature to their advantage?

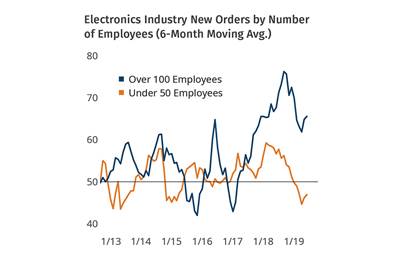

Read MoreWall Street Upgrades Near-Term Outlook for Electronics Industry

Late-term outlook projects increases in revenues and earnings in electronics.

Read MoreHow to Use 'Mapping' to Troubleshoot Blown Film Problems

Three real-world case studies show how processors solved common problems in blown film via the mapping technique.

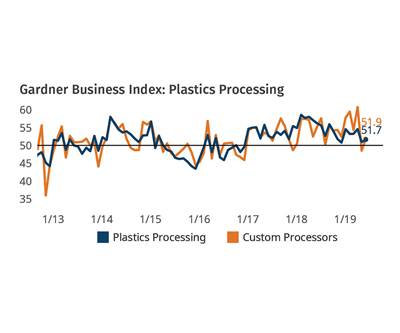

Read MoreProcessor Activity Increased in June

Plastics processing activity rose in June, at a slightly higher rate than in May.

Read MoreFast, Precise Machine Helps Tubing Processor Make the Cut

Instead of turning down a job or farming out cutting to another company because of downstream bottlenecks, Eagle Elastomer can now handle all extrusion process functions in-house.

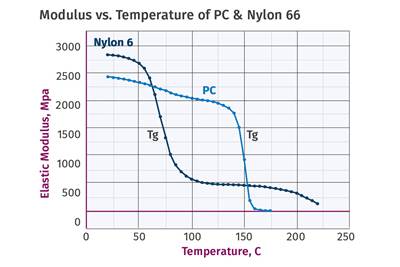

Read MorePART 2: The Importance of Mold Temperature When Processing Polycarbonate

Don’t be afraid to increase mold temperature to improve part quality when making PC parts. Take a look at a few examples here.

Read More