Articles

Clock's Ticking: Register Now for 2023 SPE Thermoforming Conference

Three-day event kicks off Oct. 24 in Cleveland.

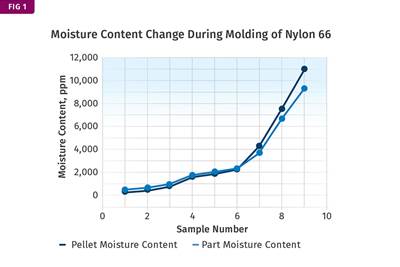

Read MoreWhat's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

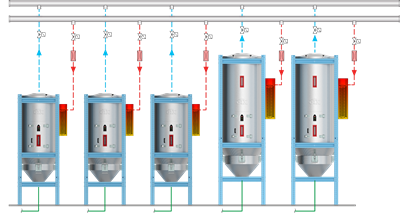

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

WatchTop Shops Benchmarking Report: Molding at the Margin

In a world of rising costs and uncertain market conditions, the ability to wring maximum profits from existing business was truly the mark of a Top Shop in 2022.

Read MoreHow to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

Read MorePrices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.

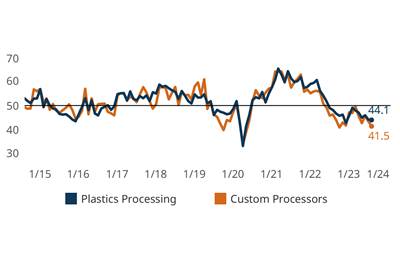

Read MorePlastics Processing Activity Held Steady in August

Monthly index indicates overall plastics processing activity stayed on its path of contraction.

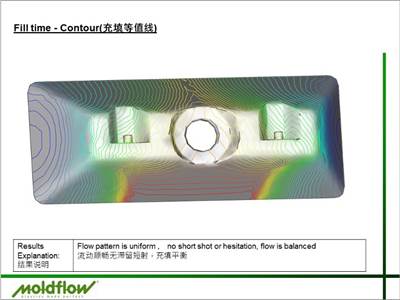

Read MoreHow to Achieve Simulation Success in Molding, Part 3: Inputs, Reports and the Analyst

Ultimately the success of this virtual, digital software falls to the real-world, analog humans requesting and completing the analysis.

Read MoreMolder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

Read MoreFoam Processor Innovates on Path to Sustainability

Nomaco does foam and only foam, innovating solutions for consumers that not only solve problems but are better for the environment.

Read MoreKraussMaffei and NIAR Propel Injection Molded Thermoplastic Composites

The maker of plastics processing equipment has placed a machine and an injection molding expert in NIAR’s ATLAS lab in Wichita, Kansas, to help molding, composites and aerospace take off.

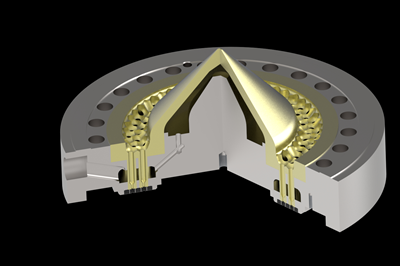

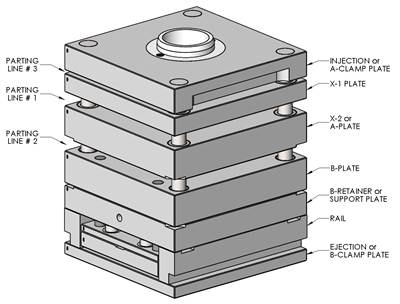

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read More