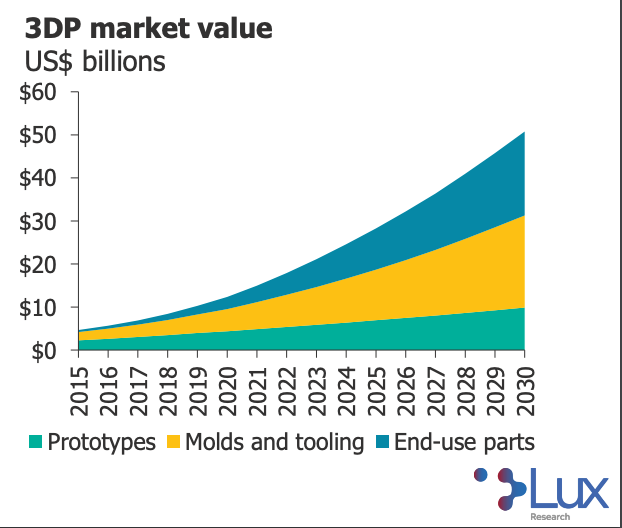

3D Printing Market Forecast to Reach $51 Billion in 2030

Lux Research states in a new report that the value of 3D-printed parts will rise at a 15% CAGR over the next decade, lead by end-use parts.

Lux Research’s new report, “Will 3D Printing Replace Conventional Manufacturing?” highlights the 3D printing market size and growth by application and material. Anthony Schiavo, research director at Lux Research and one of the lead authors of the report, said 3D printing’s benefits, including customization and personalization, the ability to create complex geometries, part consolidation, and lower costs in some cases will contribute to the technology’s growth. “3D printing will be a key in the future manufacturing landscape thanks to benefits that it can bring over injection molding, machining, casting, or other conventional methods,” Schiavo stated in a release.

The value of 3D-printed parts will rise at a 15% compound annual growth rate (CAGR) over the next decade, from $12 billion in 2020 to $51 billion in 2030. Schiavo says the largest share of that growth will be in end-use parts, which currently make up 23% of the market but will grow to a 38% share in 2030. Medical and dental industries will account for the largest share of end-use parts, reaching $4.5 billion in 2030, followed by aerospace at $3.9 billion.

Prototyping and tooling will also continue to grow at rates of 9% and 15%, respectively. Prototyping, which accounts for $4.4 billion today, will rise to $9.9 billion in 2030, while molds and tooling remain just ahead of production parts, reaching $21 billion in 2030, up from $5.2 billion in 2020.

While prototyping, tooling and end-use parts are all forecast to grow, finished parts will make up the lion’s share of 3D printing’s growth, according to Lux.

Related Content

-

Getting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.