The increased reliability of auxiliary equipment, together with the growing number of indicators and alarms contained in a processing plant, can make it easy for plant personnel to overlook, ignore, or bypass auxiliary-equipment alarms. But, as you’ll see, that approach can be both hazardous and expensive.

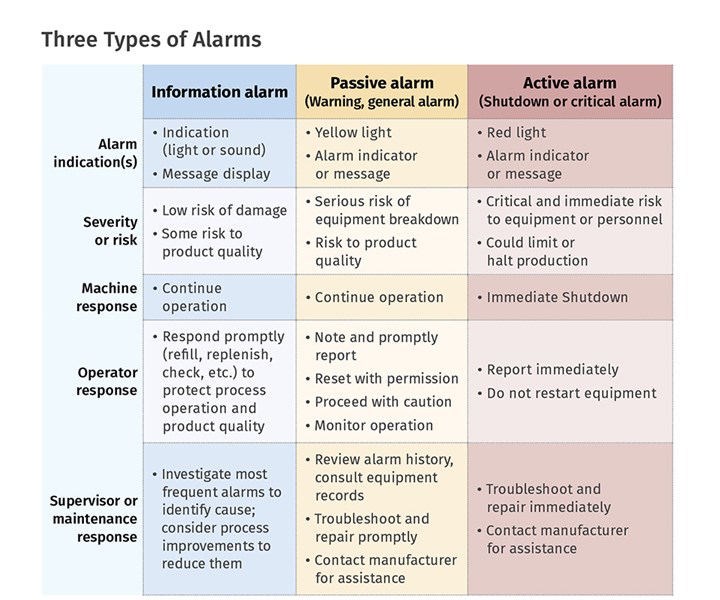

Not all alarms are created equal. Every alarm is a warning about something that is wrong, or is likely to go wrong, with equipment or production. Some alarms are literally your last chance to make repairs and prevent serious damage. How do you know when that’s the case? Let’s look at three typical types of alarms, what they mean, and how best to respond to them.

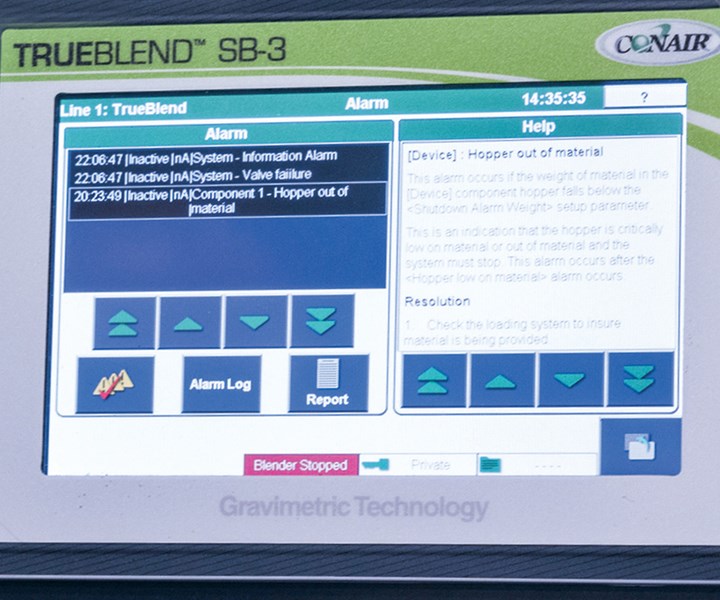

• Informational alarms indicate non-critical issues that need prompt resolution, such as a maintenance reminder or a “low material” indication. The fact that these alarms aren’t critical doesn’t mean that they can be ignored. For example, ignoring a low-material indicator on a blender, mixer, or hopper will ultimately affect part quality. Similarly, it is easy to turn off a PM reminder, but if you do so often, delayed maintenance will ultimately result in more serious alarms indicating possible or actual equipment damage.

Informational alarms indicate non-critical issues that need prompt resolution. Here, an informational alarm on a blender control indicates the need to refill a hopper that has halted due to lack of material.

Informational alarms indicate non-critical issues that need prompt resolution. Here, an informational alarm on a blender control indicates the need to refill a hopper that has halted due to lack of material.• Passive alarms (sometimes called “warnings”) indicate current problems that are likely to lead to future, serious equipment or production failures. Although passive alarms allow equipment to keep running, they should never be ignored. Think of them as you do a caution light in your car: Keep going, but proceed with caution, because something important needs attention. Operators should always record passive alarms and report them promptly to supervisors or maintenance personnel. Only after reporting and permission should operators be allowed to reset these alarms.

• Active alarms (sometimes called “shutdown” alarms) indicate critical equipment problems that will cause serious equipment damage or harm to personnel. For this reason, they trigger immediate equipment shutdown. In the event of an equipment shutdown alarm, operators must immediately alert supervisors, because prompt troubleshooting and repair by maintenance personnel is the only way to ensure safety and limit the risk of equipment damage.

Active or “shutdown” alarms indicate critical issues that can damage equipment, halt production, or injure personnel. Here, a portable dryer indicates a power fault alarm (above) and displays red lights (below), indicating shutdown.

Active or “shutdown” alarms indicate critical issues that can damage equipment, halt production, or injure personnel. Here, a portable dryer indicates a power fault alarm (above) and displays red lights (below), indicating shutdown.

The Cost of Delay

Following are examples of how delayed or inappropriate responses to alarms resulted in unnecessary and ultimately costly problems.

It is easy to turn off a PM reminder, but if you do so often, delayed maintenance will ultimately result in more serious alarms indicating possible or actual equipment damage.

The chiller that lost its cool. A processor relied on a single, large central chiller for plant-wide process cooling. The two-year-old chiller had two refrigeration circuits, each served by dual compressors, so it could handle a wide range of chilling loads with high efficiency.

The chiller proved to be reliable and resilient, continuing to operate despite occasional passive alarms through a period of eight weeks:

July 3: Passive alarm—Flow-switch fault.

July 8: Passive alarm—High-temperature alarm.

Aug. 27: Four passive alarms in two minutes: three pump faults, one high-temp alarm.

Sept. 11: Three passive alarms in 2 hr: High refrigerant pressure in Circuit 1.

Operators quickly and successfully reset all of these alarms, keeping the chiller online and keeping production running smoothly. No maintenance action was taken. But a week later, the chiller had an active alarm and shut down:

Sept. 16: Active alarm: low suction pressure, Circuit 1.

So, what happened? The active “low suction pressure” alarm that shut down the chiller meant that Circuit 1 was not providing the dual compressors with an adequate flow of refrigerant. So, the compressors not only couldn’t remove heat from the evaporator circuit, essential to maintaining process cooling, but they were starved of the refrigerant fluid needed for their internal cooling and lubrication.

Controls and alarms make it possible to monitor nearly everything on a busy production floor, from clogged or disconnected loader hoses, to warnings that could lead to shutdown of critical equipment.

Controls and alarms make it possible to monitor nearly everything on a busy production floor, from clogged or disconnected loader hoses, to warnings that could lead to shutdown of critical equipment.During the shutdown triggered by this alarm, experienced personnel might have recognized the alarm’s severity, the imminent threat of damage, and the necessity of immediate troubleshooting and repair before restarting the chiller. However, those on the scene did not. Instead, they reset the alarm and restarted the chiller, unaware that the malfunctioning circuit had recovered just enough refrigerant pressure to support the restart. Over the next 5 hr, the cycle of chiller alarms, shutdowns and restarts occurred several times until a compressor overload occurred, blowing the main fuse. Only then was the chiller technician called in.

The technician quickly found the root cause of the problem: The thermal expansion valve that should have regulated refrigerant pressure in Circuit 1 wasn’t working—the circuit board that controlled it had failed. Had the decision been made to troubleshoot any of the 10 previous passive alarms or the first shutdown alarm, the problem could have been resolved the next day by replacing the failed circuit board, at a cost of about $150 plus 1 hr of labor. Additional damage could have been prevented by temporarily reducing chiller capacity (running one circuit only) and, if needed, reducing production levels for the duration of this relatively easy repair.

Instead, the repeated restarts caused extensive damage to compressor blades, spraying metal shavings throughout the refrigeration circuit and necessitating replacement of its dual compressors, along with damaged controls and components. The total repair bill topped $15,000 in parts and labor—about 100 times more than the earlier repair would have cost. Sourcing and installing all the parts took five days, and might have taken longer, leaving production to limp along on half its chiller capacity.

Shutoff alarm shuts down process. Ignoring an equipment alarm doesn’t necessarily lead to expensive repairs, but it can be just as costly in terms of poor product quality, scrap, and lost production time. This was the case when a production manager noted a dryer that had been performing well was apparently no longer operating correctly. The products they were making showed quality problems typically attributed to an increase in moisture. Investigating further, he found that while the material was being dried at the proper temperature, the temperature profile shown by the Drying Monitor Probe inside the hopper was not very stable and material near the middle of the vessel was not as hot as it should have been. In addition, the dewpoint was also off—from sub -40 F to about -20 F.

Ignoring an equipment alarm doesn’t necessarily lead to expensive repairs but can be just as costly in terms of poor product quality, scrap, and lost production time.

The operator asserted that everything looked fine, and the dryer continued to deliver material. But the production manager didn’t like what he was seeing and looked more closely. The hoppers were cold to the touch, though even insulated hoppers are typically warm. Something wasn’t right, but why were there no alarms?

Further inspection located a hose that had come loose on the to-process blower. The leak allowed some moist plant air into the drying system, putting additional moisture into the drying air and driving the dewpoint up to -20 F. Enough air remained in the drying circuit to satisfy the pressure switches and other safeties, so the system continued to run, but the leak was clearly the reason why the temperature profile was not stable, why the material was not being dried, and why product quality suffered. But why was there no alarm?

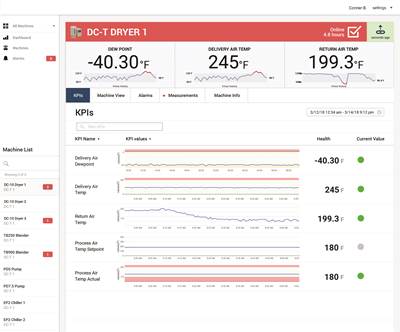

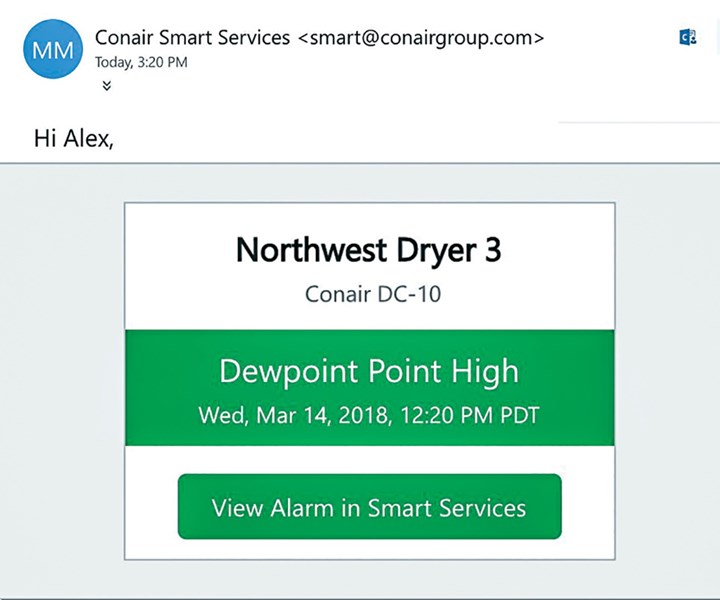

The latest auxiliary equipment is now available with configurable alarm notifications, which can send e-mails or text messages to maintenance personnel on mobile devices.

The latest auxiliary equipment is now available with configurable alarm notifications, which can send e-mails or text messages to maintenance personnel on mobile devices.It turned out that, after getting a number of passive alarms caused by the developing leak, the operator on the previous shift had adjusted the warning setpoint to a higher value, essentially blinding sensors to the growing performance problem. In addition, no alarm had been set for the Drying Monitor Probe, so temperature fluctuation due to reduced airflow was also not recognized.

Fixing the leaking hose was quick and easy, but the damage had been done: The drying hopper was full of improperly dried material. All the parts molded in the previous shift had to be scrapped. The line was shut down for the next shift while the hopper was reloaded with new resin and dried before the line could resume production. In all, the processor lost three full shifts of production.

A blender balks. A processor called to report a malfunctioning blender. According to the operator, the blender had recently been cleaned, loaded, and set up to run a very common recipe. But not long after startup, it began to display a “Batch hopper not dumping” alarm.

The operator looked through the sight glass into the mixing chamber below the batch hopper. Because the blender was running and seemed to have plenty of material, he canceled the alarm. The blender finished and released the batch to a surge bin. Despite additional dumping alarms (all were reset), the blender completed and released additional batches until it suddenly shut down.

Troubleshooting revealed a damaged load cell in the batch hopper. The load cell measures the weight of each ingredient as it is dispensed from an ingredient hopper into the batch hopper. When the proper weight is reached, the batch hopper swings open, dumping the batch into the mixing chamber.

The customer could not understand why the problem occurred, since the blender had run the recipe many times. Investigation revealed that the recipe, which called for 40% regrind, had assumed the use of pelletized regrind. However, the operator had loaded flake instead, which has a much lower bulk density. The extra volume of the flake rapidly overfilled the mix chamber, preventing the batch hopper from dumping the total weight of material called for by the recipe. This triggered the alarm. Load-cell damage occurred when the mixing blades turned on, repeatedly pressing the bulky mix against the bottom of the batch hopper and load cell, which bent under the pressure of an especially bulky load.

Had troubleshooting taken place earlier, batch weights could have been reduced before any blender damage or material waste had occurred. However, parts and labor for load-cell replacement totaled about $1000 and took the blender out of service for a day.

As these examples clearly show, there can be real financial, safety, and quality benefits for processors who consistently train plant personnel know how to properly interpret, and respond promptly to, auxiliary equipment alarms. In addition, the latest auxiliaries are now available with configurable alarm notifications, which can send e-mails or texts to mobile devices. Whether done by procedure or automation, getting the right people to see and respond to alarms at the right time is essential to reducing downtime, maintaining production quality, and preventing expensive repairs.

For first-line alarm response, technical manuals provide troubleshooting guides that review alarm conditions, explain typical causes, and provide recommended actions for resolution. You can also take advantage of additional training, which is readily available from all auxiliary equipment manufacturers.

As we have seen, the best response to a critical alarm may require a decision to take an auxiliary off-line temporarily for immediate repairs. This involves trading a small, immediate impact on production capacity against the risk of major equipment damage, extended downtime and production loss, and much higher repair costs.

Because decisions like these can be difficult to make, never hesitate to call your auxiliary equipment manufacturer. Its expertise could prove invaluable in helping you select the best possible approach at the lowest possible cost.

About the Author: Jay Kriner is customer care manager for Conair Group, where he manages a team of 18 professionals who assist customers with auxiliary equipment installation, startup, troubleshooting, and repair. He is a co-developer of SmartServices, Conair’s web-based Industry 4.0 equipment monitoring package. Prior to joining Conair in 2016, Jay worked 10 years in maintenance and reliability supervision for the U.S. Coast Guard and several companies. Contact: 814-432-6257; jkriner@conairgroup.com; conairgroup.com.

Related Content

Cost-Effective Single-Screw Feeder

New line of feeders said to be ideal for pellets, granules, and other free-flowing bulk materials.

Read MoreConnectivity for Material Handling Offers Greater Visibility

NPE2024: Motan solutions integrate data connectivity.

Read MoreSmart Works Cells at the Heart of Wittmann’s Exhibit

NPE2024: Under the theme of “It's All Wittmann,” the supplier of injection molding machines, automation and auxiliary equipment is hoping to show NPE attendees what comes with true connectivity.

Read MoreFive Quick Steps Toward Better Blending

Rising costs of resins and additives, along with higher demands for quality and use of regrind, place a premium on proficient blending. Here are some steps to get you there.

Read MoreRead Next

K 2019 Preview: Auxiliaries Showcase Connectivity & Efficiency

At press time, a handful of auxiliary suppliers shared some of their K 2019 plans, highlighting connectivity and efficiency in their planned displays.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreNew Program Guarantees Performance of Auxiliary Equipment

Web-based and cloud-powered, Conair’s new SmartServices platform is key to its just-launched ‘Uptime Guaranteed’ initiative.

Read More