Bigger Press Opens Opportunities for Molder

Acting quickly, Pittsfield Plastics arms its plant with high-tonnage Haitian press to meet customer demand and open options for more large-part molding projects.

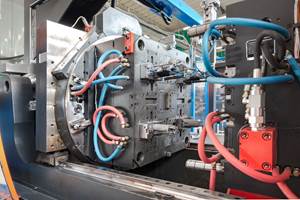

A project initiated by an existing customer prompted injection molder Pittsfield Plastics Engineering LLC (PPE) to boost its large-part molding capability. Back in November, PPE added a 1204-ton injection machine with a shot capacity of 155.6 oz to its plant in Pittsfield, Mass. PPE’s investment in the Haitian Jupiter III (JU10800 III) from Absolute Haitian is the latest in a series of upgrades the molder has made over the last five years. The machine cell is equipped with a CW15-2000 servo robot from sister company Absolute Robot. Before this purchase, the largest press at PPE’s facility was 730 tons.

PPE is an ISO 9001:2015 certified company, housed in an updated 64,000 ft2 facility with 25 presses. It runs three shifts in a 24/7 operation. Its molding operation is supported by a fully equipped tool room. PPE has also recently ramped up its R&D efforts with a new technology center housing a gamut of testing machines. In addition to custom work, PPE has a proprietary line of spools for the wire-and-cable and textile industries.

PPE’s Tom Walker, president (l); Donna Virgilio, v.p. operations and administration; and Bruce Dixon, CEO/CFO, with the new Haitian Jupiter III 1204-ton, two-platen molding machine.

PPE’s Tom Walker, president (l); Donna Virgilio, v.p. operations and administration; and Bruce Dixon, CEO/CFO, with the new Haitian Jupiter III 1204-ton, two-platen molding machine.

Bruce Dixon, CEO/CFO of PPE, recalls the circumstances that led to the purchase of the new large machine: “An existing customer had a substantial project that required a large-tonnage press and we wanted to take advantage of the opportunity. If we didn’t add a larger tonnage machine quickly, we would have missed out on the project.”

The initial job is to mold kayak seating, but Dixon has additional projects lined up for the JUIII, including electrical enclosures used in commercial real-estate development. “Our current utilization of the JUIII is about 50%, so we have custom molding availability that we plan to grow,” states Dixon.

PPE’s Dixon (l) and Walker with kayak seat molded in new 1204-ton Haitian press,

The decision to differentiate PPE from competitors with large-tonnage molding capability was based in part on Dixon’s realization that if their own 730-ton machine went down, there wasn’t a nearby molder they could outsource the work to. “There just aren’t many large machines in the New England area and we saw this as an opportunity,” he notes.

One challenge was to bring the large-tonnage machine online quickly to meet the customer’s timing. States Dixon, “Delivery was a critical factor. We began looking at Absolute Haitian’s stock-machine availability, which would have worked. But their lead time on a machine built to our specifications and needs was so aggressive, we were able to place the order from China. It was nice to have that choice.”

Installation took about four days and was overseen by Absolute Haitian’s service engineering team. “The service engineers worked closely with our maintenance supervisor throughout installation, so we became very familiar with the JUIII during startup. Like the product, the customer service from Absolute Haitian has been excellent,” Dixon notes. “Not only is our capability increased, the JUIII is more robust and runs at a more efficient pace. This acquisition puts us in a nice position for 2020.”

As a result of the energy savings from the servohydraulic, two-platen JUIII, PPE applied for and received a rebate in excess of $25,000 from its energy provider, Eversource Energy.

Related Content

Secondary Injection Unit Provides Primary Benefits for Molder

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Read MoreMolder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreOnline X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

Read MoreMedical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More