Collaboration Yields First Transparent, Conductive PC Film

Big application for new film is touch screens to speed response times.

SABIC Innovative Plastics and Cima NanoTech have collaborated to develop what’s billed as the first-ever transparent conductive polycarbonate film that could open applications in consumer electronics, household goods, automotive, architecture and healthcare, many of which currently use glass.

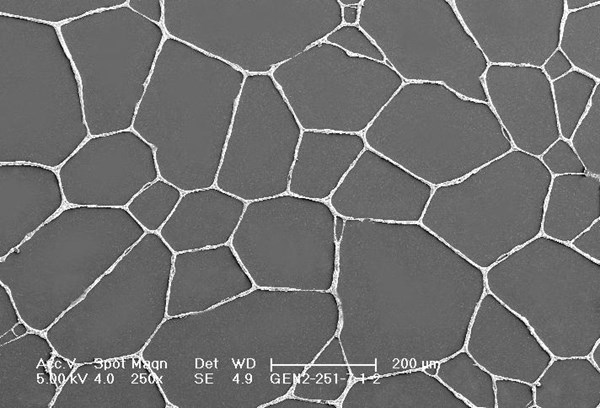

In development since late 2013, the film is cast by SABIC, Pittsfield, Mass., from Lexan in thicknesses ranging from 75 microns to 5 mm. A silver nanoparticle conductive coating, which comes as a wet dispersion from Cima NanoTech, is then continuously coated in a roll-to-roll process in a post-extrusion step. While curing, the coating then “self-assembles” into a random mesh-like network on the substrate (see image above).

Based in St. Paul, Minn., Cima NanoTech calls its technology SANTE, short for Self Assembling Nanoparticle Technology for Electronics. It’s said to be 10 times better than indium tin oxide in providing high transparency with ultra-low electrical resistance. It is also claimed to be mechanically robust, allowing the film to be thermoformed.

The new film is designed to provide “next generation” functionality, officials from SABIC and Cima NanoTech maintain. One major target is touch screens, states Jon Brodd, Cima NanoTech’ s CEO, where the film can reportedly speed up response times. The film is also said to offer “no-line” anti-fogging for automotive windows, and better EMI shielding effectiveness for electronics. It can also be used for transparent WiFi/Bluetooth antennas used in smartphones, tablets, laptops and all-in-one computers, adds Matt Gray, dir. marketing for Sabic’s consumer electronics business.

Gray says the new film is currently available for customer trials. SABIC extrudes the film itself while the coating is applied by an undisclosed partner company in North Asia. Gray says SABIC is exploring applications with Cima NanoTech for Lexan sheet.

Before its collaboration with SABIC, Cima NanoTech had used the coating primarily with PET substrates.

Related Content

-

Carbon Fiber Reinforced Nylon 12 for Injection Molding

CRP Technology’s new composite is 100% recycled from Windform XT 2.0 IMG industrial 3D printing material.

-

Design Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

-

Industrial Resin Recycling Diversifies by Looking Beyond Automotive

Recycler equips for new business in medical, housewares and carpeting.