Dow to Start Supplying Circular Polymers to Customers in 2022

Advancements in the U.S. and Europe will enable Dow to produce circular polymers from materials previously considered unrecyclable.

Dow announced several advancements in its efforts to provide customers with recycled plastic products. The advancements will enable the company to provide initial supply of fully circular polymers to customers starting in 2022. All of these efforts reportedly enable plastics that are currently unrecyclable to be recycled, including flexible plastics used in packaging, which today are typically incinerated or sent to landfill.

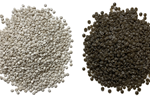

For instance, Dow and Fuenix Ecogy Group are expanding upon the companies' initial agreement to scale circular plastics production through advanced recycling with the construction of a second plant in Weert, the Netherlands. The new plant will process 20,000 tonnes of waste plastic into pyrolysis oil feedstock, which will be used to produce new circular plastic at Dow's Terneuzen site in The Netherlands.

“There is no compromise on performance—it will turn flexible waste into new raw material,” said Romain Cazenave, group marketing director packaging EMEA for Dow.

Advanced recycling is the process of breaking down mixed waste plastics into their original form to manufacture new virgin polymers. The polymers produced from this pyrolysis oil are said to be identical to products produced from traditional feedstocks, and as such, they can be used in the same applications, including food packaging.

“With our type of technology, and in combination with mechanical recycling, in the future, we can completely eliminate the disposal of waste in the environment,” said Sirt Mellema, CEO of Fuenix.

Other announcements from Dow:

- Dow and Gunvor Petroleum Rotterdam finalized an agreement to purify pyrolysis oil feedstocks derived from plastic waste. Gunvor will supply cracker-ready feedstock to Dow beginning in 2021, which will be used to produce circular plastics for customers. The purification process is necessary to ensure the pyrolysis oil feedstocks are of sufficient quality to produce new polymers.

- Dow is fast-tracking the design, engineering and construction of a market development scale purification unit in Terneuzen, the Netherlands, to provide additional capacity to purify pyrolysis oil feedstock derived from plastic waste.

- Dow has established a multi-year agreement with New Hope Energy, based in Tyler, Texas, to supply the company with pyrolysis oil feedstocks derived from plastics recycled in North America. New Hope Energy converts used plastics into pyrolysis oil feedstock, which Dow will use to produce circular plastics.

- In preparation to deliver certified circular plastic products to its customers, Dow has received or is on-track to receive International Sustainability & Carbon Certification (ISCC) for each of its major European and U.S. sites. Certification requires an independent, external audit, ensuring product supply chains are fully traceable and that Dow and its suppliers are adhering to and accelerating sustainable practices.

The advancements complement Dow's recently announced partnership with Mura Technology to support the rapid scaling of Mura's new HydroPRS (Hydrothermal Plastic Recycling Solution) advanced recycling process. The world's first plant using HydroPRS is in development in Teesside, U.K., with the first 20,000 tonne per year line expected to be operational in 2023, providing Dow with additional recycled feedstocks.

The company has set targets to enable 1 million metric tons of plastic to be collected, reused or recycled through its direct actions and partnerships by 2030, and to enable 100% of its products sold into packaging applications to be reusable or recyclable by 2035.

Dow and Fuenix Ecogy Group announce the construction of a second plant in Weert, the Netherlands.

Read Next

Specifying PCR? Find Answers to These Eight Questions

Understanding how to work with the PCR available today is critical as packaging and other products are being redesigned for circularity.

Read MoreChemical Recycling Poised to Take Off

Investments in chemical-recycling facilities abound as the industry moves closer to the Circular Economy model, accompanied by plenty of new rollouts of packaging made from chemical recycling.

Read MoreDow Partners with Mura Technology to Scale Game-Changing Advanced Plastics Recycling Technology

Dow’s collaboration to speed up development of Mura’s pioneering Hydro PRS technology that can recycle all forms of plastics.

Read More