DuPont To Address Recycling, Lightweighting, Material Selection

At NPE2015, DuPont scientists and other industry experts will host seminars on recycling and material innovation & selection for automotive, packaging, and medical devices.

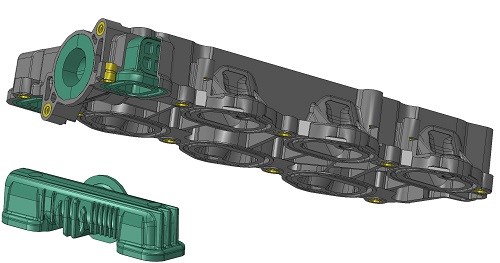

DuPont will talk about new ways that plastics can be used in various markets, including automotive. In a recent program, as seen here, Zytel HTN PPA was used to make a coolant cross-over component that weighs one pound less thatn its brazed metal predecessor.

Among the several major plastics materials companies that will have presence at NPE2015—either through a booth exhibit or through a specific conference room designation, is DuPont. Nearly all these suppliers have announced where they will be located and briefly described the materials and/or applications on which they intend to focus.

I found DuPont’s announcement of how they have structured their time there as a particularly helpful approach both for existing and potential customers and trade press alike. So, here is a rundown of their program of seminars, to be held at the Orange County Convention Center—Room W207A:

• Monday, March 23 at noon. “Material Selection Based On Feel—A Methodology For Technical Evaluation.” Presenters: DuPont technical specialists Eric Larson and Mark Schuchardt. These experienced DuPont Performance Polymers designers will talk about how the senses, such as feel, sight and hearing, can be engaged in the earliest stages of product development and material selection to bring new innovative ideas to light.

• Tuesday, March 24 at 10 a.m. “DuPont Zytel Plus Nylon—Material Solutions For Long-Term Use At High Temperatures.” Presenter: DuPont scientist Rodica-Sinziana Himmeldirk. This session will address how this new advanced material can support the automotive industry’s drive to increase vehicle fuel efficiency by reducing weight.

• Tuesday, March 24 at noon. “Not Your Average Recycling Talk.” Co-Hosts from DuPont Industrial Polymers: Shane Campbell, N.A. Industrial & Consumer Director and David Dean, Research & Development Director. DuPont and partner companies (see below) will talk about shifting mindsets about recycling, the latest advances in recycling machinery, and out-of-the-box success stories of recycled materials used in everyday items such as packaging, carpeting and decking.

Partner panelists: Kim Holmes, senior director, SPI’s Recycling and Diversion; Manfred Hackle, CEO, Erema Engineering; Frank Endrenyl, PET project leader, Carpet America Recovery Effort (CARE); Darcy Meyers, global marketing director, packaging,PolyOne Corp.; and, Neville Browne, president and director, CarbonLife Industries.

• Wednesday, March 25 at 10 a.m. “Collaboration As The Catalyst For Innovation: Driving Differentiation.” Long-time DuPont collaborator John Winzeler, president of Winzeler Gears, will talk about how collaboration borne from deep relationship speeds development and excites innovation.

• Wednesday, March 25 at noon. “How Plastics Can Do More To Drive Automotive Lightweighting.” Presenter: Jeffrey A. Sternberg, Dupont’s global automotive technology director. Taking weight out of vehicle systems and components tops the automotive industry’s list of strategies to lower emissions and improve fuel efficiency and DuPont Performance Polymers shares a strategy to find new opportunities.

• Wednesday, March 25 at 2 p.m. “Engineering Polymer Solutions To Support Design And Innovation In Drug Delivery Devices.” Presenter: William L. Hassink, global marketing manager for DuPont’s Medical Healthcare div. DuPont Performance Polymers’ technical experts lend navigation to what can appear to be a bewildering range of materials to choose from when designing discrete drug delivery devices.

• Thursday, March 26 at 10 a.m. “So What’s So Special About Surlyn Specialty Ionomer?” Co-hosts from DuPont Industrial Polymers will be Shane Campbell, NA industrial & consumer director and David Dean, research & development director. Presenters include other researchers and technical fellows. If you're not attenting ANTEC, but still want insights into cutting-edge advances in to the unique Surlyn capabilities, stop by for this interactive panel discussion. DuPont scientists will discuss the latest advances which help improve puncture resistance in packaging, bounce strength and anti-aging, and nylon modification.

• Thursday, March 26 at noon. “The Possibilities Of Packaging & Industrial Polymers.” Presenter is Timothy Libert, application development programs manager, and other DuPont Packaging & Industrial Polymers technical Experts. These polymer scientists in the field of packaging and industrial polymers will address some of the industry’s toughest challenges and invite attendees to bring their toughest issues to this panel discussion.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastic Technology’s Plaspec Global materials database.

Related Content

Carbon Fiber Reinforced Nylon 12 for Injection Molding

CRP Technology’s new composite is 100% recycled from Windform XT 2.0 IMG industrial 3D printing material.

Read MoreNew CRM Streamlines Quoting for Automotive Molder

Eliminating the need to contact each supplier for every individual quote, a new CRM for automotive supplier Axiom Group tracks past quotes as well as industry history to generate fast, reliable RFQs and more.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreAdditive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More