Engel Has Grown By 14%; Will Expand Headquarters

The company says almost all regions have made a contribution to this success.

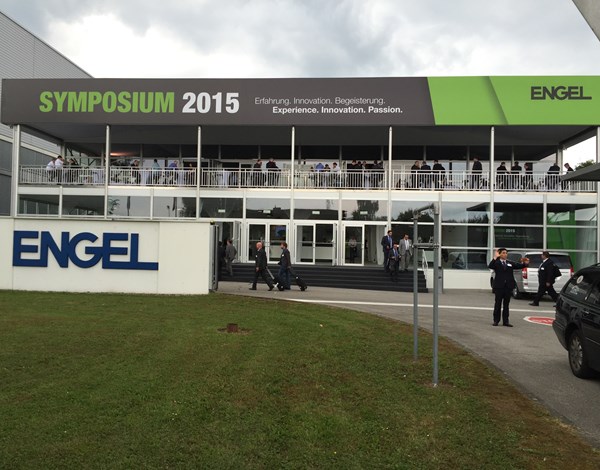

The Engel Symposium 2015 was recently held in St. Valentin and Linz, Austria. Every three years, the injection molding machine manufacturer invites its customers, partners and (lucky for us) the media to gorgeous Austria for the in-house exhibition.

If one word could describe the symposium it would be: upbeat. Generally speaking, the company is feeling pretty good about the current state of business. Engel reported a record breaking turnover of 1.07 billion euros ($1.19 billion) in the 2014-2015 financial year that closed the end of March, according to Peter Neumann, CEO of Engel. In comparison to the previous year, the company achieved an increase of 14%. Neumann said that almost all regions have made a contribution to this success. Specifically in North America, Engel is expecting sustained growth as many companies have brought their production back to the U.S. Another reason for growth in the U.S.: the replacement of old machinery.

Still, to remain competitive, companies must attract the best talent and focus on keeping them. Neumann says this is the key factor in how Engel is preparing for future. For the new fiscal year, the company plans to make further investments in its sites worldwide, in the distribution and service structures and also in the apprentice workshop.

One focus for investments in the current 2015-16 fiscal year is on the headquarters in Schwertberg, Austria. In the summer of this year, Engel will already begin with the construction of a new building to the south of the factory site, expanding the Technology Centre that was built in 2009. The development, distribution and customer service departments will all add more personnel. "With that we are laying the foundation to solidify our very strong presence in the European market and to continue to grow in America and Asia," Neumann said. Shanghai experts for the individual business units have also been added.

A larger apprentice workshop will also be located in the new building and furnished with new equipment. The company says it will provide its staff with optimal working conditions already as trainees with "lots of daylight, ergonomic workplaces and an open atmosphere."

Around 150 of the more than 170 Engel trainees worldwide are in Austria and they are given training there for nine technical professions. Those workers are integrated into the assembly of the machines from the very beginning. The machine components that are prepared by the apprentices are used for the on-going production. "For those just starting in the profession, that is a huge motivational factor. We will be intensifying this integration with the newly designed apprentice workshop," Neumann said.

The company says about 98% of the apprentices are retained. Besides Austria, Engel has training programs for technical professions in Germany and in China.

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Process Monitoring or Production Monitoring—Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

-

Is There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.