First PC/ABS from Post-Consumer Recycled Plastic Underway

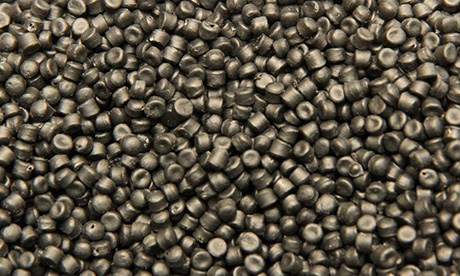

MBA Polymers looks to be first in producing post-consumer PC/ABS pellets from shredded WEEE.

My colleagues alerted me last week to the news that what appears to be the world’s first production of post-consumer PC/ABS pellets from shredded waste electrical and electronics equipment (WEEE) is now underway. I took one look and saw it was durable goods recycling and technology company MBA Polymers and company founder Mike Biddle immediately came to mind as twice I’ve been fortunate to hear him speak within the last three years at SPE’s Global Plastics Environmental Conference (GPEC).

Biddle launched MBA Polymers in 1994 in Richmond, Calif. with a vision of being the first company to automate plastics recycling from very complex waste containing materials such as metals, glass, and various plastics, and on a large scale. He and his team of chemical, mechanical, electrical and mining engineers developed a separation process—for which there is a mix of different patents--of an energy-efficient, cost-effective way of extracting plastics from complex waste streams. MBA’s proprietary processes are said to use less than 20% of the energy needed to product standard virgin resins. The company is now recognized as the world’s leading multi-national pioneer in recovering plastics from complex waste streams like computers, electronic appliances, automobiles, and household wastes.

In mid-2013, the company closed its pilot-scale facility in Richmond and moved its R&D and headquarters to its 126,000-sq.ft. facility in Workshop, England. At the 2014 GPEC event I attended, Biddle said the move was made because Europe does more recycling and offers more R&D opportunities, at least in the near term. While the U.K. plant is reportedly the world’s largest and most advanced facility for recovering plastics and rubber from automotive shredder residue, MBA’s plants in Austria and China have been focused on WEEE since 2006.

It is MBA’s Kematen, Austria facility that just began to produce post-consumer PC/ABS from WEEE, for which excellent mechanical properties are claimed, with production expected to steadily build up through the year. It will be distributed under the tradename EvoSource. and aimed at automotive, electrical and consumer electronics applications. In electronics, for example, designers will be able to specify EvoSource PC/ABS to increase the use of post-consumer recycled plastics in order to achieve the higher ratings required by the Electronic Product Environmental Assessment tool (EPEAT).

Said MBA Polymers CEO Richard McCombs, “The decision to develop PC/ABS products reflects our determination to meet the growing demand from customers for post-consumer recycled plastic as well as extending our commitment to sustainable growth. Every 1% increase in the usage of our waste benefits our return on investment enormously. MBA is unique in being able to extract the degree of value that we are achieving today from WEEE.”

As for Mike Biddle, he remains a non-executive director of MBA Polymers. Last year, he started up San Francisco Bay area Material Solutions, an organization that aims to help other “clean-tech entrepreneurs” shorten their path to developing their businesses. The company also consults with a wide variety of companies, organizations and communities around the world to capture material benefits from putting “circular economy” principles to work—including turning waste into resources and designing more favored new products with sustainable supply chains.

Search for more recycled resins in PT’s materials database.

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More