GM Using Stratasys 3D Printing Systems for Ventilator Tooling Production

GM’s director of additive manufacturing, Ron Daul, talks with Plastics Technology about the company’s investment in 3D printing technologies.

Share

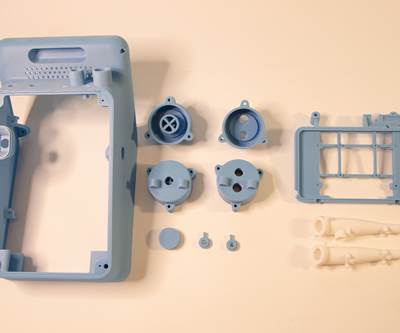

GM 3D printed tooling used for critical care ventilators on Stratasys systems.

We continue to report about how 3D printing is helping to produce equipment to help combat the COVID-19 pandemic. GM details how the company’s expertise in additive manufacturing helped turn automotive production to medical production as well as the long-term growth potential of AM technology.

In April, GM entered into contract with the U.S. Department of Health and Human Services to deliver a 30,000-unit order for critical care ventilators, in conjunction with Ventec Life Systems, by the end of August. The company reverse-engineered part data for tooling fixtures from the original ventilator manufacturer, and started 3D printing them the next day. All 3D printed tooling used for critical care ventilators was created on Stratasys systems.

“3D printing doesn’t know if it’s printing a glovebox or a ventilator, and we very quickly were able to pivot to the ventilator production,” said GM’s Director of Additive Manufacturing Ron Daul.

When the company requires more 3D printing capacity, there is an automatic offload path to Stratasys Direct Manufacturing for parts on demand. According to the companies, this helps GM run at a high utilization rate for its existing machines, expanding in-house capacity when it can ensure it has a sustained need for it.

“With the Ventec project, we were tasked to see what we could do from a tooling standpoint with the Stratasys 3D printer instead of having to fabricate metal tooling,” said Dominick Lentine, GM team lead, additive manufacturing. “It allowed us to quickly get parts in hand to not only see it digitally on CAD files, but also engineers on the floor can see how this product that they were initially unfamiliar with come together. It also allowed us to prototype a lot of parts, similar to what we do with vehicles with prototyping and 3D printing the vehicle parts, we did the same thing with many Ventec parts.”

Material innovation and machine repeatability have made a difference, the companies stated. For example, nylon 12 carbon fiber is a composite material containing 35% chopped carbon fiber by weight, which reportedly translates to an exceptionally high strength-to-weight ratio, even in places subjected to heavy vibrations. As a result, heavy parts that would have previously required metal can now be 3D printed in plastic. And production-grade systems like the Stratasys F900 have been designed to not only perform to a high degree of precision but also consistency so that every part is as identical as possible.

GM’s Future with 3D Printing

GM has used 3D printing since 1989 for prototyping. About 75% of the parts in the prototype of its 2020 Chevrolet Corvette were 3D-printed, and GM now has 3D printers installed in many production facilities around the world. The company is increasingly moving beyond prototyping to production-related applications like tooling.

The company added 17 production-grade Stratasys FDM 3D printers to its fleet at the end of 2019 and has been turning to 3D printed tooling for speed, weight reduction and cost efficiency on its production lines.

“With the pace of change in modern industry accelerating and business uncertainty increasing, 3D printing technology is helping us meet these challenges and become more nimble as a company,” Daul said. “We’ve been on this journey for more than 30 years, but 3D printing is becoming even more widespread at our company, with more than 700 employees now trained to use the technology. Additive manufacturing is consistently providing us more rapid and efficient product development, tooling and assembly aids, with even more benefits to come.”

GM, which has been steadily upping its investments in 3D printing over the past couple years, is betting that the business benefits will continue long after the current crisis subsides.

An April 2020 study by SME Media found that 25% of U.S. manufacturing professionals were planning to change their supply chains in response to the pandemic, and 3D printing was the top choice (with robotics) of 11 manufacturing technologies for post-COVID investment. The technology can be used to 3D print spare parts, produce end-use parts closer to assembly, help manufacturing lines retool faster, and develop new and better prototypes more quickly.

Related Content

Automotive Awards Highlight Emerging Technologies

Annual SPE Automotive event gives nods to several ‘firsts’ as well as sustainability.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreMolder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreRead Next

Additive Manufacturing and Injection Molding Increasingly Complementary in Covid-19 Crisis

The coronavirus crisis has often simultaneously required the speed of additive manufacturing and the scale of injection molding.

Read MoreStratasys Announces Winners of the CoVent-19 Challenge to Design New Ventilator

The three winners will receive a total of $10,000 in credits for 3D printing from Stratasys.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More