How Troubleshooting Challenges in the Existing Recycling Ecosystem led to a Revolution of the Industry

Cassie Bradley, INEOS Styrolution’s sustainability and circular economy manager, details how advanced recycling technologies and their integration into communities across the country (and the globe) is key to a future circular economy for plastics.

Advanced and mechanical recycling should act as valuable complements to ensure material is recycled both effectively and efficiently.

Traditionally, mechanical recycling has been the only available technology for recycling plastics. Mechanical recycling has several advantages, such as technology maturity and low energy requirements. However, this method alone cannot create a circular economy. Providing communities with new options available through advanced recycling technologies in addition to mechanical recycling technology offers a more robust solution.

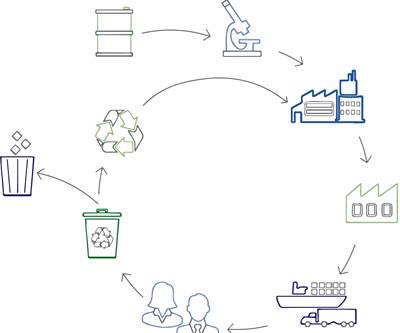

In recent years, technologies for advanced recycling have evolved in response to increased attention surrounding post-consumer plastic waste. The exploration of new recycling methods, such as advanced recycling technologies, aims to address the challenge to develop sustainable solutions for post-consumer plastic waste and pave the way for a more sustainable ecosystem. This new ecosystem, commonly referred to as a circular economy, will allow consumers and companies to continue benefiting from the unparalleled and robust qualities of plastics, all while greatly reducing their environmental footprint.

Advanced recycling technologies allow for recycling at a greater scale than simply using traditional recycling methods. Certain advanced recycling methods such as depolymerization allow for the infinite recycling of the same material again and again without impacting its usability (no downcycling).

However, advanced methods may encounter some hurdles as they scale up; utilizing large-scale facilities will still require significant capital and time to implement, and while scale is certainly a major benefit of these technologies, so is the demand for large feedstock volumes. In this way, creating a truly circular economy for plastics is dependent on cooperation between industry and the public to ensure plastic waste collection and sorting are also scaled to levels consistent with advanced recycling capabilities.

Rather than either option serving as the primary recycling method, advanced and mechanical recycling should act as valuable complements to ensure material is recycled both effectively and efficiently.

Advanced Recycling and Polystyrene

Advanced recycling refers to many different types of technologies. These technologies convert plastics into a variety of products such as monomers, base chemical feedstocks, or polymer additives, depending on the specific technology used. Examples of advanced recycling methods include depolymerization and pyrolysis, among others. Specifically, depolymerization is a process by which a polymer is reduced to its original monomer form on a molecular level and then re-polymerized with the result of creating new plastic materials and products. Thus, allowing us to take the “single” out of “single-use products.

When examining the future of plastics, polystyrene remains key to understanding how a circular economy could come to fruition. Polystyrene has many inherently sustainable properties compared to alternatives, which enable it to play a substantial role in designing products and packaging for recycling or sustainability.

Its material strength and barrier properties often allow it to be used as a single layer in applications such as food packaging. This single-layer design eliminates multiple material layers that cannot be adequately separated during the recycling process. It also means each package requires less material overall in the first place.

Polystyrene is one of the most easily sortable plastics due to its identifiable and unique molecular structure. It can also be recycled using both mechanical and advanced recycling technologies. Utilizing an optimal combination of available solutions to recycle this material makes it incredibly valuable as we move towards the circular economy for plastics.

Overcoming Some Challenges of Advanced Recycling

One challenge facing advanced recycling is simply education about what it really means. The term “advanced recycling” covers such a broad spectrum of technologies that blanket statements regarding the pros and cons of specific solutions are often misinformed and inaccurate, such as the false assumption that all advanced recycling processes produce fuels instead of monomers or base chemicals. The plastics industry is working hard to educate one another and the public on the progress of new technologies and recycling as a whole.

While offering benefits, the large scale of advanced recycling facilities may pose a challenge of sourcing significant volumes of plastic waste feedstock. These necessary volumes may not be supported by the capacity of the existing collection and sorting infrastructure, which remains limited across North America. This ties back to the cooperation required between industry and the public to ensure plastic waste collection and sorting are also scaled to levels consistent with advanced recycling capabilities.

While revolutionary advances in recycling can significantly help recycling centers meet the impending boom in increased demand for recycled materials, more action is needed to improve existing waste and recycling infrastructure.

The next step is for public and private organizations to collaborate by pooling knowledge and resources to ensure our recyclers are equipped with the tools they need to collect and utilize these valuable materials. It is in the interest of all participants in the value chain from producers, consumers, and recyclers that plastic is recovered, recycled and repurposed again and again.

Advanced recycling is necessary for the circular economy to become a reality while continuing to preserve the carbon emission benefits of valuable plastic materials. While some hurdles remain on the path to that circular vision, certainly none are insurmountable. We should let our passion drive us and let the data guide us towards a future without plastic waste.

Cassie Bradley is INEOS Styrolution’s Sustainability and Circular Economy Manager, leading these initiatives for the company across the North America region. Cassie works with leaders in the emerging polystyrene recycling industry to create valuable partnerships and grow the Polystyrene Circular Economy up to meet INEOS Styrolution’s scale as a global leader in styrenics.

Related Content

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreRead Next

Ineos Styrolution Talks Closing the Loop on Polystyrene

The company is collaborating with several companies on several solutions, including depolymerization.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More