New Proprietary Bioplastic Presents Alternative to PLA and PHA

Startup Verde Bioresins’s PolyEarthylene blend has been custom engineered to 82 different grades for use in both single-use and durable applications.

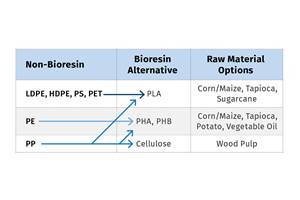

We have been steadily reporting on developments in bioplastics, particularly PLA and PHA, including new grades, grades for additive manufacturing, and production scale-ups. Recently, I was contacted by innovative and sustainable materials science startup Verde Bioresins, Santa Monica, Calif., which appears to have developed a proprietary bioresin—primarily derived from a combination of sugar cane and other plant-based feedstock, which is touted to have improved performance compared to PLA and PHA, allowing it to be used in both single-use and durable applications.

Moreover, since its founding in March 2020 by a team of industry veterans with decades of experience in polymer engineering, compounding and advanced polymer chemistry, led by president and CEO Brian Gordon, the company’s PolyEarthylene blend has been custom-engineered to 82 different grades to meet customers’ economic and biodegradation goals.

The fully plant-based PolyEarthylene is formulated to be an attractive food source for microorganisms at the end of its lifecycle, allowing for complete and natural mineralization. The material is also BPA-free, extremely durable, compostable and as flexible and strong as conventional plastics. It also complies with FDA Title 21 for food contact compliance and is recyclable. Verde touts its proprietary biopolymer as a responsibly designed, high-performance, and bio-based alternative resin that can be used to “drop in” manufacture “plastic” goods, including durable goods.

I asked Verde’s Gordon to discuss how PolyEarthylene differs than established bioplastics PLA and PHA. “Broadly, PLA lacks the holistic properties needed for durable goods production. Among the most widely-used bioplastics in the market today, only PLA and PHA have optimal end-of-life solutions. However, PLA is not only temperature sensitive, leading it to potentially break down during its product cycle, but also it is not landfill biodegradable. PLA is also UV-sensitive, brittle, and has comparatively lower processing window as well as melting temperature to PolyEarthylene.”

“PHA exhibits some disadvantages including a lower strain-at-break, a narrow processing window, a slower crystallization rate, and a higher cost compared to both biobased and petroleum-based polymers. As it stands, PLA and PHA are both more fit for single-use applications vs PolyEarthylene which is fit for both single-use applications as well as durable goods, Gordon expounds.

He concedes that PHA vs. PLA has certain performance properties that are more comparable to PolyEarthylene and offered this breakdown of feature comparisons. The latest development of PHA is perceived as a burgeoning technology for the bioplastics industry, however, its production and performance limitations create major challenges for manufacturers and brands in search of drop-in biobased solutions, he noted. “When it comes to value proposition, price, performance and efficiency are three major points of contention for companies looking to transition towards renewable biomaterials, and PolyEarthylene is the only scalable and durable biomaterial solution designed for the drop-in method to fulfill market demand at a cost competitive rate.”

Godon noted that they are in the process of completing the ASTM D6400 compostability test, and will definitely have some data to share at the conclusion of this process. “We have just passed the D5338 milestone (ASTM’s standard test method for determining aerobic biodegradation of plastic materials under controlled composting conditions) and will be conducting other components of the test in the next month.”

At present, Verde’s team of polymer chemists and plastics engineers are focused on third-party certifications based on the ASTM testing standards for landfill biodegradation (D5511) and compostability (D6400). Verde is seeing extremely positive results in various grades within its initial portfolio. Its compostability testing is currently approaching the 150-day milestone of the 180-day testing cycle and is projected to see over 70% biodegradation in 150 days.

Verde is currently working with various Fortune 100 CPG brands and distributors to offer a diverse portfolio of PolyEarthylene grades for applications such as films (including bags), injection molded and blow molded goods, and coatings. Current applications under development include containers, consumer goods, electronics, health and beauty, single-use and re-useable food packaging and restaurant supplies.

Gordon confirms that the company does not license its technology. Instead, they are looking for industry brands and partners.“Currently, we manufacture all of our PolyEarthylene resins in-house at our new state-of-the-art R&D and manufacturing center in Southern California and we are in the process of scaling up production.

Related Content

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More