Compounding: Part 1 of 2: Demystifying Devolatilization

Very little has been written about this critical topic, and most of what has been published is theoretical. Here’s some practical guidance to help you better understand the process and improve your operation.

Devolatilization is the process by which unreacted monomer, solvent, water, dissolved gases, or other undesirable volatile contaminants are removed from a polymer melt or solution. It is a mass-transfer process driven a combination of thermodynamic and diffusional variables, with the design of the machine impacting both of these parameters. It is driven by superheating the volatile component, followed by exposing the melt or solution to a rapid decompression.

Single-screw or multi-screw extruders, or any number of custom or commercially available stripping devices such as wiped film evaporators, have been used for devolatilization. The choice is largely driven by the nature of the polymer to be stripped, the concentrations of volatiles, and other processing actions required for the product.

Despite the major commercial significance of devolatilization, little has been written on the topic. Only four texts have been published, and while the technical literature fares a bit better, most of the treatments are highly theoretical in nature and are few in number compared with topics such as screw design, mixing, morphology, etc.

A valuable source of design information on devolatilization, however, can be found in the patent literature. There is a plethora of patents and applications on screw and vent designs, non-screw devices, devolatilization processes, vent stuffers, etc., that when sifted through will contribute to a better understanding of the technology.

This column is intended as a general guide to the topic to help you better understand the process and perhaps improve your own operation. Discussion will focus strictly on single- and multi-screw devices. Devolatilization can be demystified by focusing on a few basic design and operational parameters and optimizing the conditions that will both protect the product and lead to the lowest residuals.

Elements of a Devolatilization Zone

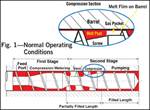

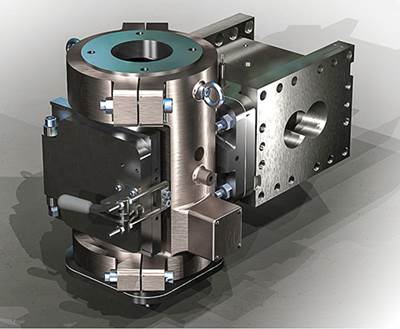

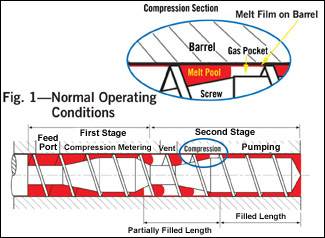

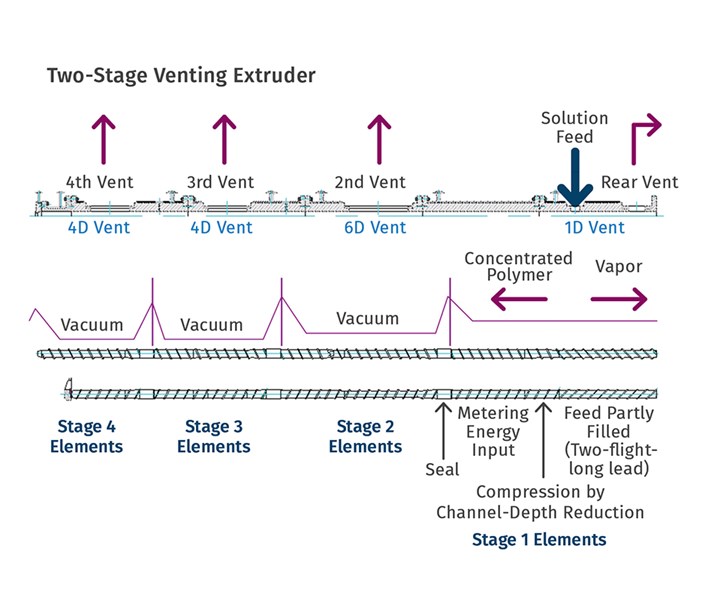

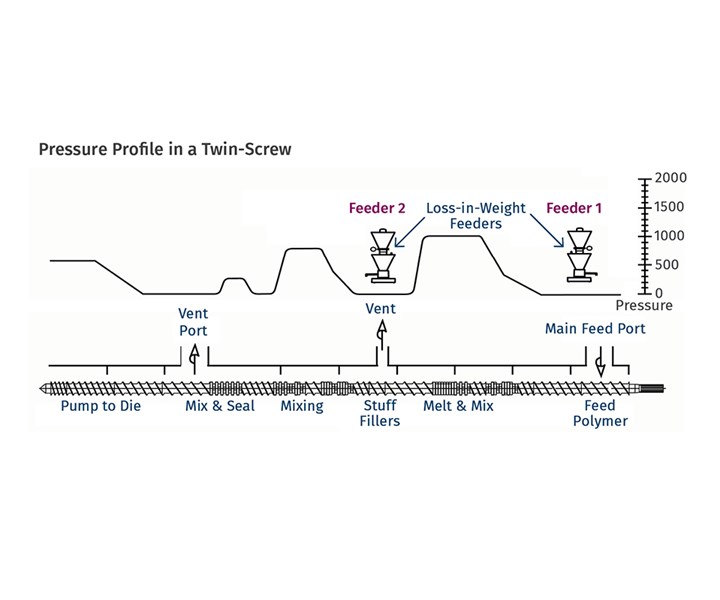

Whether in a single-screw or multi-screw extruder, a typical devolatilization zone consists of a portion of a screw that is partially filled, isolated between two sections that are filled with melt. The filled regions are generally created by non-pumping elements—either compounders, blisters, or the die or exit of the extruder itself. Figure 1 shows a twin-screw design with multiple vents and the associated sealing element. Figure 2 shows the seals, screw elements, and associated pressure profile in a typical vented twin-screw extruder. In this instance the second vent is used for a feed addition, but the design is similar for devolatilization.

FIG 1 Shown here are the elements of the sealing, pumping and devolatilization screw sections. (Source: NFM Welding)

FIG 1 Shown here are the elements of the sealing, pumping and devolatilization screw sections. (Source: NFM Welding)The rear or upstream seal is created by neutral or reverse compounding elements, a blister, a cylinder, or other restrictive means in the screw(s) such that air cannot pass from the rear of the extruder into the devolatilization (DV) zone. A neutral or reverse element forces the screw to be completely full at that seal, and for some turns of the screw upstream of that seal, to generate pressure to pump over the seal. This isolates the vacuum of the DV zone from the feed throat or other zones of the extruder.

The downstream or front seal is established in a similar manner, and often in the case of simple twin-screw operations or a single-screw extruder, the discharge of the extruder through a die serves as this seal. The goal again is to prevent vacuum from pulling through the downstream screw elements and disrupting the performance of the vent. Depending on the type of extruder, its length, and functional zones, the upstream seal may be fed from the melting zone of the extruder or may come from another mixing, blending, or venting operation. The downstream seal may be the die itself or discharge into another venting or additives-incorporation portion of the machine.

The design of the downstream seal is a bit more involved than the upstream seal, in that if the restriction is too tight or too close to the downstream face of the vent, the throughput too high, or the screw speed too low, the filled portion of the screw or screws can back up under the vent opening and flood up into the vent, eventually blocking the outlet and piping to the vapor takeoff system.

For a twin-screw extruder, changes in the screw speed can alter the stability of the seals.

It is important that the operator understand how the vent will respond to changes in operating conditions. For a twin-screw extruder, changes in the screw speed can alter the stability of the seals. An increase in screw speed will shorten the filled length behind both the front and rear seals, making them more susceptible to failing. Decreases in screw speed will result in longer filled lengths behind each seal. For the downstream seal, this runs the risk of polymer backing up into the vent.

Unit or Finishing Operation

Devolatilization is somewhat unique as a plastics process, since it can be employed both as a unit operation for isolation of a polymer melt from a solution, or as a finishing step for removing trace contaminants from a polymer that might otherwise harm the product or pose a risk to the public.

As a unit operation, devolatilization is an effective means of isolating a polymer from a solvent or monomer when the reaction is not carried out to completion. For a broad family of polymers whose polymerizations are highly exothermic (chain polymerizations such as acrylics and styrenics) conducting the polymerization in a solvent or the monomer itself provides a convenient way to control the exotherm. Typically, these reactions are carried to 40-60% completion in a stirred-tank reactor, followed by a stripping and recycling operation where the monomer or solvent is removed and recovered and recycled back to the stirred-tank reactor.

FIG 2 Seals, screw elements, and associated pressure profile in a typical vented twin-screw extruder. In this case, the second vent is used for a feed addition, but the design is similar for devolatilization. (Source: Leistritz Extrusion)

FIG 2 Seals, screw elements, and associated pressure profile in a typical vented twin-screw extruder. In this case, the second vent is used for a feed addition, but the design is similar for devolatilization. (Source: Leistritz Extrusion)The mix is generally dropped into a multi-vent devolatilizing extruder or a combination of a flash device followed by an extruder. Typical machines would be fitted with two, three, or four vents that successively drop the solvent concentration to near zero.

As shown in Fig. 1, the reactor feeds (in this case, syrup) to the twin-screw extruder, which has four vents down the length of the machine. One of the significant advantages of screw extruders over other stripping devices is that the screw continually and evenly reheats the polymer following each devolatilization zone.

A good rule of thumb for vented machines is that each vent can bring the concentration of volatiles down by an order of magnitude. For example, a triple-vented machine can bring a 50%-solids feed down to less than 0.1% residuals with little difficulty.

The Push for Low Residuals

Devolatilization is almost invariably employed at or near the discharge of an extruder (or injection molding machine) to reduce or eliminate any residuals left in the melt. Reducing residuals to levels below a few hundredths of a percent is not uncommon.

The drivers for reduction in volatiles in finished polymers and plastics come from several quarters. First and foremost, residual solvent, monomers, or other volatile contaminants often have an adverse effect on the physical properties, physical appearance, stability, or aging performance of the final article. Residual volatiles will alter the color of a finished article and/or can adversely affect the UV light stability, and long-term strength.

Regulatory compliance—either industrial or governmental—will often dictate the level of residual contaminants in a plastic, especially for food and beverage, medical, or human-contact applications. Generally, the lower the residuals of any sort in a finished polymer, the safer and more durable the product.

A good rule of thumb for vented machines is that each vent can bring the concentration of volatiles down by an order of magnitude

In contrast with chain polymerizations, where devolatilization may be part of a unit operation, for step-growth polymerizations (nylons, PET, etc.) where there is less of a risk of thermal runaway, devolatilization will be employed to strip away the remaining monomers and other small molecules left over from the polymerization process itself.

In theory, it would be possible to strip a polymer melt completely of volatile residuals. There are two practical limitations on how low one can go. One is for certain types of polymers (chain-polymerization types, for example) that are subject to unzipping or depolymerizing with excessive heat and residence time. It is quite possible to have a well-designed vacuum vent and screw design run under full vacuum, only to see the residual volatiles increase as a result of unzipping or depolymerization rates exceeding the rates of devolatilization. While this is a frustrating experience, there are a variety of means to maximize the stripping rates without undue thermal history for the melt.

The other practical limitation is the damage to the polymer caused by excessive shear stress and temperature. Poor color, chain scission, branching reactions and other forms of degradation can occur while pushing devolatilization performance. Ultimately there is a trade-off between the residual levels and damage to the polymer.

Devolatilization is a valuable unit operation and finishing step for polymer production and, in some cases, injection molding. It serves as a means of isolating and purifying the polymer.

What devolatilization will not do is remove non-volatile contaminants from a polymer melt. Larger molecules, such as dimers and trimers, which would have a high boiling point and/or low vapor pressure, will not be extracted by devolatilization and must be removed via extraction or reactive processes. The higher the boiling point of a contaminant, the higher the melt temperature and rates of surface-area regeneration, and the lower the partial pressure, must be to strip those materials.

In our next installment we’ll focus on machine design parameters and thermodynamic variables that control devolatilization as well as practical matters that facilitate good devolatilization performance.

About the Author: Rob Jerman has developed twin-screw extrusion systems for devolatilization, mixing and compounding, and reactive systems for over 30 years and has significant experience in product and process development in fluoropolymers. He has his own consulting firm, Extrusion Technology and Innovations. Contact robertejerman@gmail.com

Related Content

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreFive Quick Steps Toward Better Blending

Rising costs of resins and additives, along with higher demands for quality and use of regrind, place a premium on proficient blending. Here are some steps to get you there.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

Solve Venting Problems on Twin-Screw Compounding Extruders

Compounds must be free of voids and volatiles or else the material will cause subsequent processing problems. Here’s how to ensure your venting is effective.

Read MorePrevent Streaks & Specks From Vented Extruders

With vented extrusion, small amounts of melt can hang up on the screw and degrade, eventually resulting in streaks or specks that hurt the appearance of the extruded product.

Read MoreExtrusion Know-How: The Whys & Hows (& Ifs) of Vented Extruders

Vented or two-stage screws only make sense when volatiles must be removed in order to make a satisfactory product.

Read More