Screw-Recovery Problems Call for Special Screw Design

In injection molding, the penalty for using a general-purpose screw in an application that has special requirements often takes the form of longer cycle times. Barrier designs can help.

This is particularly the case in packaging and other applications where high outputs or thin-wall parts are essential. For one Nordson Corp. customer producing large thin-wall parts, making the switch from a standard screw to a custom-designed Xaloy screw has resolved a cycle-time issue, increasing productivity and profitability.

In one of its North American plants, this customer was using a general-purpose screw to process 100% recycled HDPE on a 1000-ton Ube injection molding machine. Shot size was 3750 g. The molder’s problem was a screw recovery phase that was too long. It was an issue that is all too common in injection molding, often involving processing of virgin or recycled PP or HDPE.

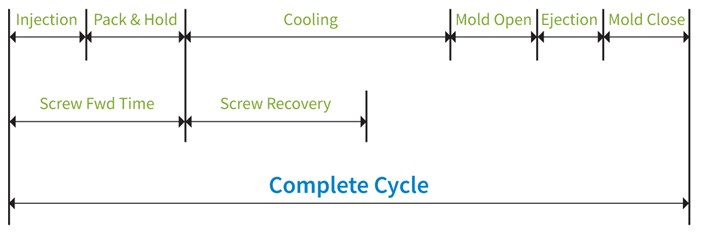

Recovery time is the time it takes for the screw to rotate back into its set position. It takes place during the cooling phase. (See Illustration 1.) A common rule of thumb is that recovery time should be 1 or 2 seconds less than the set cooling time. If recovery time exceeds this cooling time, the overall machine cycle increases.

In a robust process, recovery time should be less less than the set cooling time.

Nordson custom designs screws to help with recovery issues. The Xaloy MeltPro barrier screw, for example, melts more efficiently than a general-purpose screw. While reducing recovery time, the MeltPro screw can produce a lower melt temperature and reduces the need for back pressure.

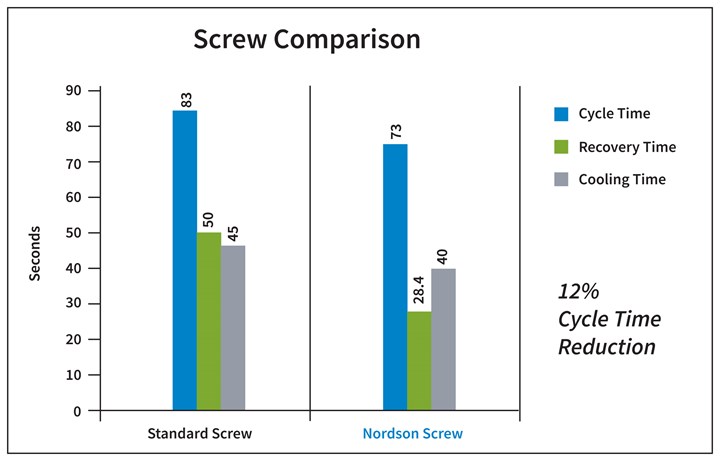

The customer reported significant improvements since using the MeltPro screw. Recovery time dropped, allowing cooling time to be reduced and cycle time decreased by 12%. (See Illustration 2.). As a result, output increased by 14%, going from 1041 to 1184 parts per day.

The MeltPro screw reduced recovery time, which subsequently cut cooling and cycle time.

How the Barrier Screw Reduces Recovery Time

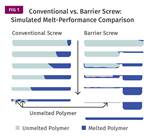

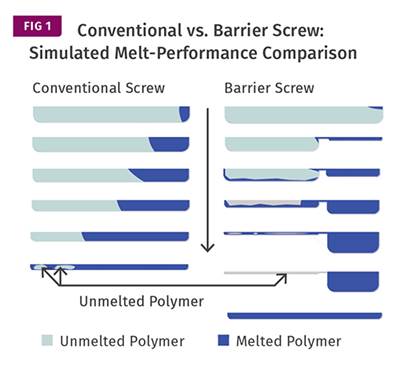

A standard screw may pose difficulties in applications requiring high outputs because it has limited melting efficiency and may generate high melt temperatures—which in turn prolong cooling time. In the transition or compression zone, the decrease in channel depth raises the shear rate, adding heat to the molten polymer. Further downstream, the efficient melting of solids against the heated barrel stops, and there is breakup of the solids bed in the screw channel. The remaining un-melted materials are distributed throughout the screw channel, rather like ice cubes in water. The result is a less efficient melting process. In addition, heating of the melt continues in the shallow metering section of the screw.

The polymer that is finally injected into the mold from a standard screw may thus contain un-melted pellets or exhibit variations in temperature or viscosity. The result is poor properties and poor color mixing. It is possible to achieve greater mixing by using a screw with reduced channel depth, but this is done at the expense of overheating and reduced output, since the volume of resin conveyed per screw revolution is smaller.

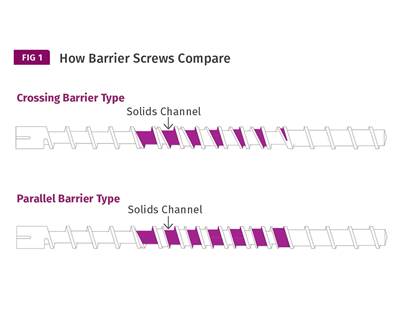

The primary reason for using a barrier screw instead of a standard screw is to prevent breakup of the solids bed and provide a more efficient melting process. Multiple barrier screw designs are available. For this customer, Nordson recommended the MeltPro screw because it achieves the highest throughputs in comparison with other barrier screws while exhibiting low melt temperature and high melting efficiency, as well as requiring minimal back pressure.

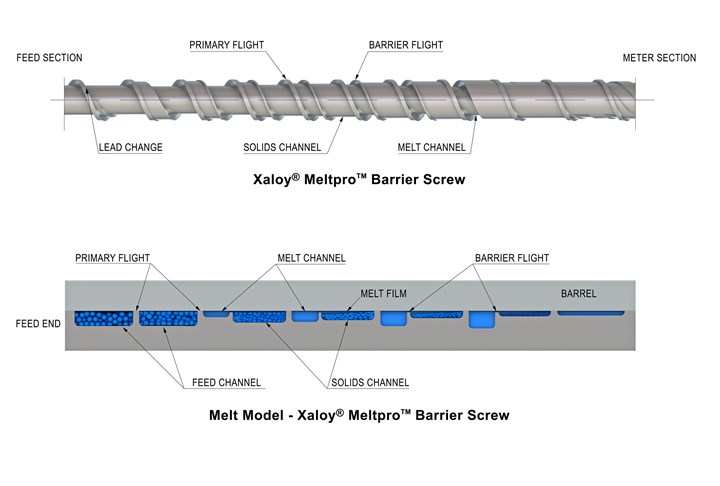

Here is detail about the operation of the MeltPro screw (see Illustration 3):

Nordson Xaloy says its MeltPro barrier screw balances high throughputs with low melt temperature and high melting efficiency.

- The feed section establishes solids conveying in the same way as a conventional screw.

- At the beginning of the transition (compression) zone, a second flight is started. This flight is called the barrier or intermediate flight and it is undercut below the primary flight O.D. The barrier flight separates the solids channel from the melt channel.

- As material progresses down the transition zone, melting continues as the solids are pressed and sheared against the barrel, forming a melt film. The barrier flight moves under the melt film and the melt is collected in the melt channel. In this manner, the solids pellets and melted polymer are separated and different functions are performed on each.

- The melt channel is deep, giving low shear and reducing the possibility of overheating the melted polymer. The solids channel becomes shallower, forcing the un-melted pellets against the barrel for efficient frictional melting. Breakup of the solids bed does not occur to stop this frictional melting.

- The solids bed continues to get shallower, reaching a plateau before tapering to the meter depth.

- Now all of the polymer has melted and gone over the barrier flight. Melt refinement can continue in the metering section. In some cases, mixing sections like a patented Xaloy Pulsar section are also included downstream of the barrier section. In general, the melted plastic is already fairly uniform upon exit from the barrier section.

Proper screw design is often the key to optimizing an injection process. Standard or general-purpose screws provide adequate plasticizing in many applications. In more challenging applications, a wide range of barrier and mixing screw designs is available to meet specific injection molding requirements.

Related Content

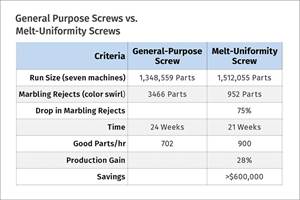

Improve Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

Read MoreXaloy Invests in New R&D Center

Xaloy is investing in a new R&D Facility for plasticizing equipment in northeast Ohio with aid from JobsOhio R&D Center Grant.

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Read MoreExtreme Coatings Names Jackson Director, North American Sales

Company also extends its global manufacturing footprint.

Read MoreRead Next

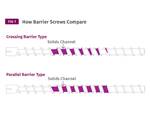

Barrier Screws: Not All Are Created Equal

Let’s take a deep dive into parallel and crossing types and see where each fit in.

Read MoreOptimize Barrel Temperatures For Barrier Screws

Extruder operators often don’t compare the barrel-zone temperatures to the recommended processing temperature for the resin being run.

Read MoreUnderstanding Solids-Bed Breakup in Barrier Screws

Barrier screws all but eliminate problems associated with solids-bed breakup. But if they do occur, tremendous pressures can develop, causing screw wear.

Read More