The “Holy Grail” of PC Glazing Appears on the Sporty Electric Tommykaira ZZ

Teijin has developed the world’s first “pillar-less” PC windshield for a commercial car.

There’s been a lot of activity taking place in the automotive PC glazing arena within the last few years, starting with non-windshield glazing such as fixed rear-side windows and rear windows, with developments led by companies such as SABIC and Covestro.

Most recently, this has included a new-generation Buick GL8 and GL8 Avenir luxury multi-purpose vehicles, which sport what is reportedly the largest PC rear-quarter window in the world. It is molded from SABIC’s Lexan PC. Yet another, was a new electric concept car featured by Covestro at K2016, which features a wrap-around glazing made of transparent Makrolon PC.

Just this week, we found out that what appears the “holy grail” of PC glazing—the world’s first full-width (“pillar-less”) PC windshield—has made a splash in a commercial vehicle. The news came from Japan’s Teijin Ltd., that the windshield, made from the company’s Panlite PC and produced by GLM Co., Ltd—an EV (electric vehicle) manufacturer launched by Kyoto University, appears on the sporty electric vehicle Tommykaira ZZ.

PC resins are prohibited from use in the windshields due to automotive safety standards. Teijin’s PC-resin window, thanks to its high resistance to abrasion and weather, meets new Japanese standards that will become effective in July, paving the way for its use in the Tommykaira ZZ. Meanwhile, GLM expects to acquire street-ready certification for the Tommykaira ZZ fitted with Teijin’s PC windshield, and then will offer the window as an option by this autumn.

Teijin also plans to market its PP resin window concept for automakers in the U.S. and the EU, where demands for properties equivalent to new standards for safety and security are increasing. By thickening the perimeter of its PC window, Teijin says it managed to eliminate the need for the A-pillar, or vertical support that divides the windshield and front window. As a result, the transparent PC resin achieves unobstructed sight lines for safer driving and more enjoyable viewing. The integrated PC-resin pillar-less window is also 36% lighter in weight than a conventional front window with an A-pillar.

Teijin provides PC solutions for plastic glazing, including for train windows, automotive panoramic roofs and quarter windows, leveraging PC’s competitive advantages over glass—including 200 times greater resistance to impact and just half the weight.

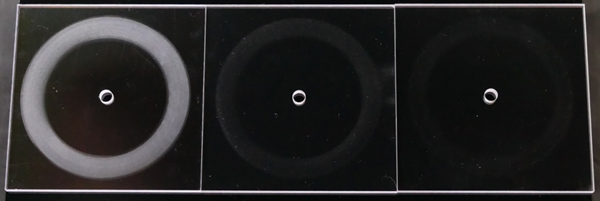

This past March, the company developed a new plasma-enhanced chemical vapor deposition (plasma CVD) hard-coating technology for the wet hard-coat layer, which is said to offer the same level of abrasion resistance and weather resistance as glass windows. The company collaborated with Tsukishima Kakai Co. to develop a plasma CVD pilot plant to treat large PC windows with uniform coatings of plasma CVD. Large surfaces, including the size of actual vehicle’s resin windows and those with complex curves are now being glazed at the pilot plant.

The company says it’s leveraging its lightweight, strong, high-performance materials and integrated composite technologies as one of the key focuses of the transformation strategies for the group’s medium-term management plan, under which the company aims to become a multi-material components supplier that works closely with automakers to develop various applications for lightweight automotive bodies.

Meanwhile, SABIC sources weighed in on PC glazing activities with the following points:

● Various automakers have executed a “pillar-less” style windscreen design in concept vehicles through the years.

● Design trends support the use of PC glazing in windscreens (and in other window applications). There is interest from automakers in PC glazing to create complex curvatures on the edges of windscreens and take advantage of part-integration opportunities.

● SABIC has expertise and experience working with the industry on “pillar-less” style design approaches.

● SABIC automotive glazing experts played a support tole in the informal group that provided guidance on the proposed regulatory rule in Europe to allow for PC glazing in windscreens. This legislation was introduced under ECE R43 in 2015 and is now used as a reference for other countries.

Related Content

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More