Thermoforming Machinery Specialist Kiefel Expands its Natural Fiber Expertise

With its new technology center, Kiefel is investing in its own sustainable packaging research activities with a focus on natural fibers.

A new technology and materials center was recently opened by German thermoforming machinery specialist Kiefel GmbH at its Freilassing headquarters as the company is increasingly investing in its sustainable packaging research activities with a focus on natural fibers. The market leading company for plastic thermoforming and joining technology opened up the additional business area of "Fiber Thermoforming" internationally last year.

In the future, the center will be used for material research and tests, as well as for sample production and machine demonstrations. Explains head of central development Matthias Hausmann, "The Packaging Technology Center and the connected Material R&D Center, deepen our materials expertise and allow us to support our customers even more closely in the development process for everything related with fiber materials, products and machines.We are thus consolidating our role as a holistic solutions provider."

With this investment, Kiefel intends to develop and use even more sustainable technologies, processes and materials. From materials research to production, the Material R&D Center is the starting point for product developments for customers. Here, Kiefel researches, analyzes, and categorizes various natural fibers and designs coating concepts for packaging made from natural fibers. These are then tested on pilot systems and optimized for the manufacturing process.

The Material R&D Center complements Kiefel's Applied Polymer Research Center in the Netherlands, which focuses on materials research into recycled and biobased plastics. In the Packaging Technology Center in Freilassing, Kiefel demonstrates its extensive machine portfolio for the production of fiber packaging to its customers: The Natureprep KFP series for high-quality stock preparation of natural fiber pulp and the Natureformer KFT series systems, on which various fiber products, e.g. bowls, cups, secondary packaging for electronics, coffee capsules or flower pots can be manufactured. The company tests tools on the systems, carries out machine tests and small batches of sample production. Prototype testing also takes place here. Added Hausmann: "With our concept we achieve solutions that are optimally tailored to our customer requirements from material to machine.”

Taking responsibility for the environment and society A sustainability exhibition is also integrated into the Packaging Technology Center. Head of sustainability at Keifel Cornelia noted, "We have been involved in various initiatives for a number of years, for example helping improve plastics recyclability. As a mechanical engineering company, we want to actively take responsibility in order to become the leading solution provider for the development and implementation of the most sustainable technology.” The "Rethinking Concept" has long anchored this claim in the company's DNA, she explained. The aim of the concept is to rethink materials, machines, processes and products, to ultimately achieve the ideal, most sustainable design for the customers. This is the case, for example, if the end product can be easily recycled in the circular economy or can be biodegraded. In addition to this, Kiefel has now set goals in order to holistically identify sustainability potential and utilize it efficiently.

Kiefel's customers include well known manufacturers from the medical engineering, refrigerator and packaging industries. With its own technology and material centers, the company offers turnkey solutions and provides support in partnership from product development through machines and tools to service. Kiefel has a global presence thanks to its own sales and service branches in the U.S., France, the Netherlands, Russia, China, and India, as well as sales partners in more than 60 countries. The company owns the Dutch thermoform toolmaker Kiefel Packaging BV, as well as the Austrian company Kiefel Packaging GmbH, a supplier of tools and automation solutions.

Related Content

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreMaking a Play With PHA

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

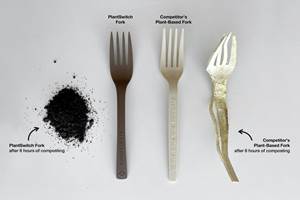

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More