Try This Lower-Cost Purging Method

You might be able to reduce purging times and save money by scheduling processing jobs in order of the increasing material viscosity. But to get started, you'll need shear rate/viscosity curves for your polymers.

Purging is a necessary task for extrusion processors that change polymers for different production runs. There are many approaches to purging, and some are better than others. For extrusion processors that run different materials, the biggest time and polymer savings may not be in some magical purging technique or compound but in the production-planning process.

Ideally, to reduce purging time and cost, processing jobs should be run in the order of increasing viscosity based on their normal range of processing temperatures. Of course, that’s not always practical, as production runs tend to be to be scheduled when orders are received or as requested. That said, when purging can be done this way it can provide an enormous reduction in waste by simply purging one polymer with another.

Depending on the product requirements, a small amount of residual polymer from the previous processing run will not necessarily negatively affect the next run, meaning that complete purging is not always absolutely necessary. This is not obvious or published information, and some testing will be required to determine how much, if any, residual polymer can be tolerated in the next product. For example, simply changing color sequences can affect the acceptability of a small amount of residual polymer from the previous production run. However, it’s seldom that any polymer contaminated with any purging compound can be used, so it’s worth a look to find the acceptable level of cross-contamination.

It’s easier to purge a lower-viscosity polymer with a higher-viscosity polymer than vice versa. When processing two grades of the same polymer, the melt flows need to be considered; and the one with the lower melt flow will purge the one with the higher melt flow better than vice versa.

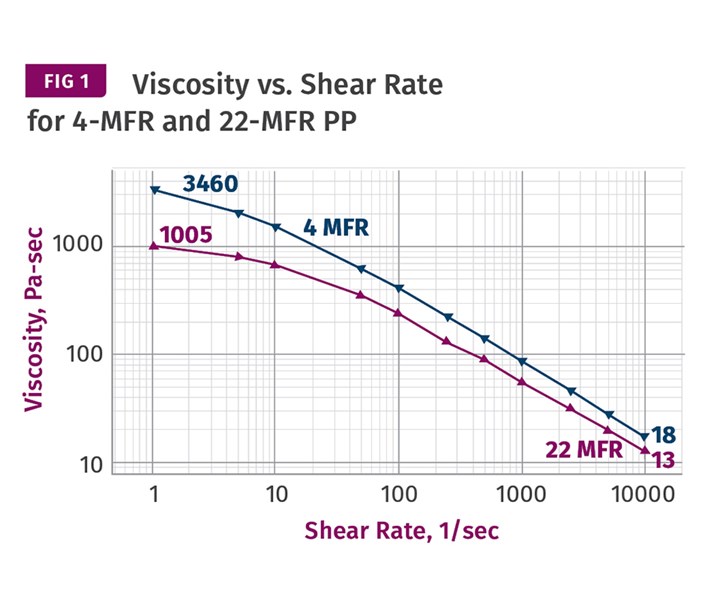

As Fig. 1 shows, the 22-MFR PP will not effectively purge the 4-MFR PP because they melt at the same temperature and the viscosities are substantially different. Keep in mind that these are log/log plots and the difference in viscosity of the 4 and 22 MFR at a shear rate of 100 sec-1 is a ratio of almost 2:1.

The 22 MFR PP will not effectively purge the 4 MFR resin because although they melt at the same temperature, the viscosities are substantially different.

It’s easier to purge a lower-viscosity polymer with a higher-viscosity polymer than vice versa.

In addition to following the practice of increasing viscosity for purging, the use of increasing melting point can also be deployed with crystalline polymers. With amorphous polymers this is difficult as they soften at their glass-transition temperature, which is much lower than their processing temperatures, and then simply get progressively softer as the temperature rises. Selective-temperature purging on that basis would require a whole series of shear-rate/viscosity curves well below the processing temperature, which are not generally available. As a result it’s less complicated to work just with shear-rate/viscosity curves for all your polymers at their normal processing temperature when evaluating their purging effectiveness.

To make the most effective decisions in planning your sequence of jobs, having the shear-rate/viscosity curves is an absolute necessity. Just having melt-flow rates will only work with the same polymer (Fig. 1) as the melt-flow testing for different polymers is done at different test conditions and cannot be easily compared. Shear-rate/viscosity curves for each polymer are usually shown in their normal processing range, so by comparing the curves it’s easy to pick the one that would have the highest viscosity.

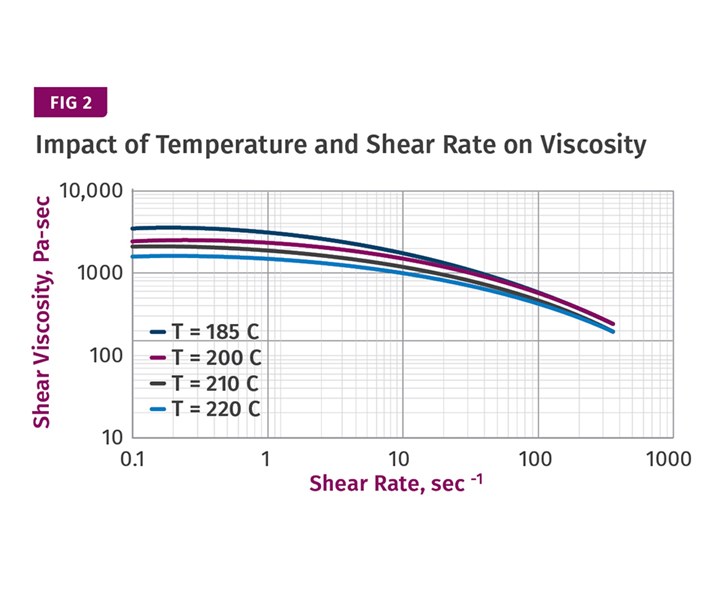

Most polymer viscosities are not affected nearly as much by temperature as by shear rate in their normal processing ranges, so minor variations between the temperatures at which the shear-rate/viscosity curves were tested can generally be overlooked, as shown in Fig 2. In a typical processing range of 100 sec-1 the viscosities are very similar over the 35° C (63° F) temperature range.

Most polymer viscosities are not affected nearly as much by temperature as by shear rate in their normal processing ranges. In a typical processing range of 100 sec-1 the viscosities of most polymers are very similar over the 35° C (63° F) temperature range.

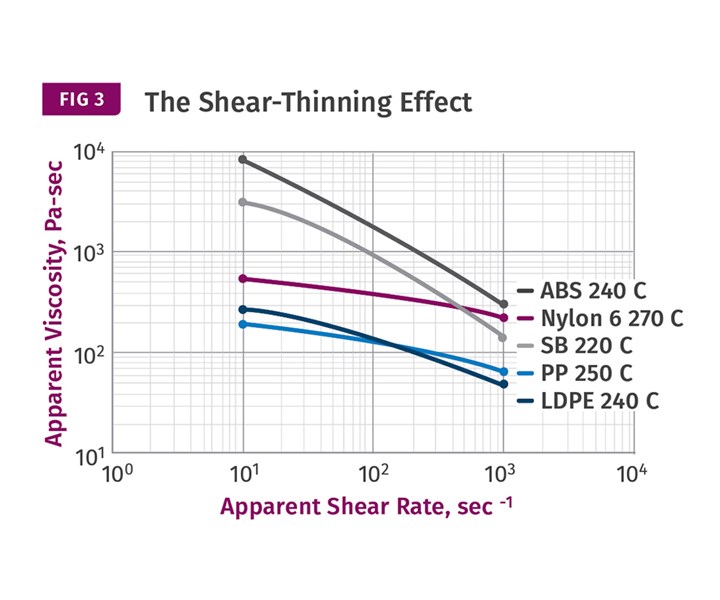

I usually consider 100 sec-1 a good shear-rate range to consider for purging because it’s typical of a medium to high extruder speed. Figure 3 shows that ABS or nylon 6 will be a good purge for SB. However, the viscosity curves for PP and LDPE cross over at about 100 sec-1 shear rate, so at lower speed you could possibly purge LDPE with PP, but the situation reverses at very high speeds. Through the whole range of shear rates for PP and LDPE, the viscosities actually do not vary much, making them generally poor choices to purge one another. All of these polymers process in a relatively narrow range of temperatures, so there is only a minor advantage to selecting the one with the highest melting point as the purging material. As you can see, without the viscosity curves it’s often difficult to arrive at a clear judgment.

100 sec-1 is a good shear-rate range to consider for purging because it’s typical of a medium to high extruder speed. So ABS or nylon 6 will be a good purge for SB.

There are many “home-grown” procedures for purging—such as throwing in a cup of water to steam-clean the screw—but in general the higher the screw speed the more effective the shear forces are in cleaning the screw and tooling. However, in some cases the tooling can have “eddy” currents in less streamlined areas, so oscillation of the screw speed from low to high can be effective. Changes in output not only change the volume of flow but the viscosity. As you can see from the shear-rate/viscosity curves, the viscosity is much higher at very low shear rates and can be effective at purging.

This is often referred to as the “disco method” developed by DuPont. Oscillation of the barrel and tooling temperatures can be added to further improve this method. For example, temporary higher tooling temperatures can improve purging, as that has only a minor effect on the polymer temperature and viscosity except immediately adjacent to the walls. Naturally care should be exercised not to raise the tooling temperatures too high so that burning or degradation occurs on the walls.

Changes in output not only change the volume of flow but the viscosity.

Regardless of the procedure used, development of a sequence of processing conditions to purge effectively between polymers can provide enormous savings in time, polymer and purging compound. But again, to be effective you need shear-rate/viscosity curves for your polymers before you can get started. They can generally be obtained from your polymer supplier, the internet or by sending small samples to a test lab. Then start evaluating the best sequential purging schedule by evaluating the time and scrap generated by each sequence. There is money to be made in the results.

About the Author; Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreTroubleshooting Flow Surging in Single-Screw Extruders

Surging can cause lower production rates, higher scrap rates, material degradation and higher labor costs. Here is a guide to troubleshooting this problem.

Read MoreUnderstanding the Incumbent Resin Effect

When you are looking to replace an existing resin with a new one, in trials sometimes the “incumbent” resin will cause gels and other defects. Here’s what to look for.

Read MoreRead Next

How to Avoid Problems When Using Commercial Purging Compounds

The best approach is to implement and standardize a three-step program to ensure you are purging in the best and most cost-effective manner possible.

Read MoreFollow These Tips to Power Up Your Purging Process

A properly executed purging process can save processors thousands a year in lost production while helping them increase output and avoid scrap. Here’s how to optimize your results.

Read MoreHow to Use Commercial Purging Compounds in Extrusion

CPCs are considered most often for injection molding. However, they also can provide the same benefits to extrusion processors.

Read More

.jpg;width=70;height=70;mode=crop)