UBQ Partners with Polymer-Metallization Specialist Polymertal to Create Lightweight, Sustainable Material for Complex Assemblies with Metallic Functionalities

Polymertal’s cutting-edge metal plating processes enable production of cost-effective hybrid metal-polymer parts for automotive, aerospace, communications and industrial sectors.

In late April, I reported on a partnership between UBQ Materials, an Isreali climate tech developer of advanced materials made from unsorted household waste. with compounder Teknor Apex to include UBQ’s sustainable plastic substitute in the latter’s latest line of sustainable TPEs. A globally patented sustainable plastic substitute, the UBQ material is converted entirely from unsorted municipal solid waste, including all organics and non-recyclable plastics, that have been diverted from landfills. UBQ already has been adopted by leading industry brands for manufacturing durable products with reduced environmental footprint, while the partnership with Teknor marked the first time UBQ will be used in TPE compounds for consumer products, automotive, industrial, and building & construction industries

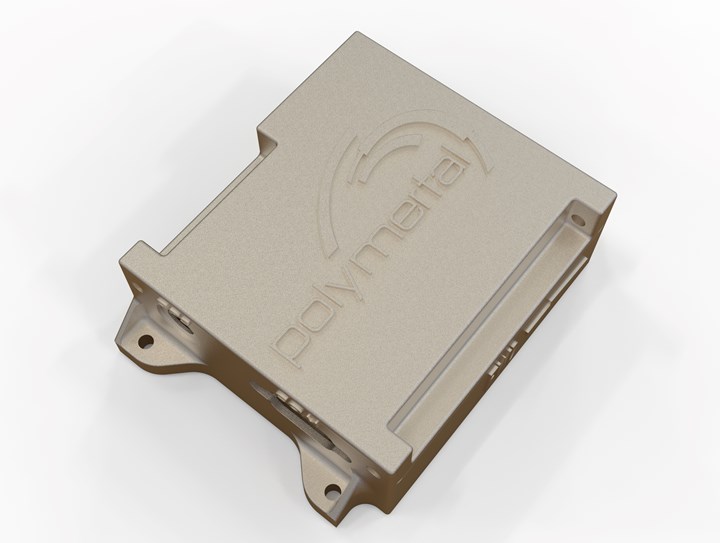

UBQ Materials has also partnered with Israel’s polymer-metallization specialist Polymertal, which develops cutting-edge metal plating processes for the creation of complex, cost-effective metal-polymer hybrid parts. Through this partnership, Polymertal is developing SPP-50XX, a new sustainable material with metallic properties that contains the UBQ material in the base substrate, This enables the material to achieve a lower carbon footprint--as compared to aluminum, bringing roughly a 50% reduction in CO2 emissions, as verified by World Watchers.

More specifically, SPP-50XX is comprised of 20% UBQ and 80% PP. On top of this substrate, a layer of copper and nickel of varying thicknesses serve as the metal plating. Surfacing a polymer substrate with a lean metal plating allows SPP-50XX to remain lightweight and exhibit key metallic properties, including durability, stiffness, heat resistance and electromagnetic shielding. A key challenge for sustainable materials in competing with lightweight metals like aluminum is to achieve the necessary toughness, thermal resistance and electromagnetic shielding, features essential to applications across automotive, industrial and consumer product manufacturing.

Said Polymertal’s CEO Ran Carmeli,“We are proud to launch our sustainable materials series, the S series, including SPP-50XX and its climate-friendly thermoplastic, UBQ. Countless applications require materials that are lightweight, withstand high-temperature environments, and are thermally and electrically conductive. SPP-50XX exhibits all these features, and the presence of UBQ brings sustainability earlier in the supply chain, making it even easier for manufacturers to reduce the overall carbon footprint of their end products.”

We recently asked Guy Varon, Polymertal’s v.p. of business development & sustainability to clarify the status of commercialization and availability of the new material series.

PT: Is Polymertal making the material commercially available in the North American market—how and when?

Varon: It will be available worldwide, including the North American market. Initially, the materials will be manufactured in Israel and distributed to the U.S. Once there is an increase in demand and traction of projects that will consist of more than 100,000 units/year, dedicated U.S. operations will be initiated. In the meantime, we’re closing a collaboration agreement with a big manufacturer in South America and North America that will support all the material manufacturing locally. It is expected to be publicly announced in the coming weeks.

PT: Is the material containing UBQ compounded by Polymertal?

Varon: Polymertal oversees the entire process, and different elements are handled by various supply chain partners. Compounding itself happens through one of these supply chain partners. After compounding and injection molding, Polymertal processes the metal plating in-house.

PT: Could you provide an example of end-use component you are initially targeting for this material?

Varon: We have produced an EMI (Electro-Magnetic Interference) shielding case with this material. It is a component that exists in every vehicle and system that has power electronics inside. These need to be protected in order to be fully functioning during operation. If they are not protected with a shield, they will cause a failure and could malfunction during operation. Presently, they are manufactured through aluminum die-casted materials. We intend to replace them with our new SPP-50XX material series and significantly improve the sustainability while maintaining the performance.

Related Content

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

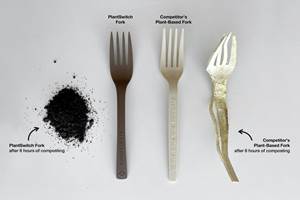

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MorePrices for PE, PS, PVC, PET Trending Flat; PP to Drop

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Read MorePolymer Science for Those Who Work With Plastic — Part 1: The Repeat Unit

What are the basic building blocks of plastics and how do they affect the processing of that material and its potential applications in the real world? Meet the repeat unit.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More