Drying

Dryers are used to minimize or eliminate problems that moisture in the plastics cause during processing. Includes resin drying; hygroscopic resins; desiccant dryer; wheel dryer; vacuum dryer; drying PET; drying PC; drying ABS; drying nylon.

ESSENTIAL READING

VIEW ALLBozzelli’s Guide To Specifying a Dryer

Here's a list of 17 things to do when looking for new drying equipment.

Read MoreWhy (and What) You Need to Dry

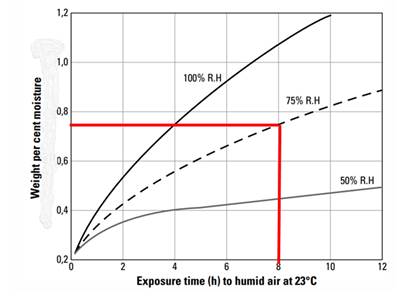

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreFollow These Seven Management Tips for More Consistent Resin Drying

Equipment and advice sure help, but ultimately, good management makes the difference.

Read MoreSpring Tips for Dryer Maintenance

The warm, humid weather really puts a strain on both the regeneration and process, so it is important that everything is in perfect working order. The time to check is now.

Read MoreWhat You Need to Know About Drying Specialty Nylons

PPA is being used more frequently by molders for demanding high-heat applications in automotive and other markets. While in the nylon family, it does not dry quite like nylon. Follow these tips.

Read MoreLatest Drying News And Updates

PiovanGroup Announces Transition In Leadership In North America

John Erkert ascends to Regional CEO position for North America as industry veteran Kirk Winstead retires.

Read MoreStreamlined Drying Process Speeds Up Changeovers

NPE2024: Maguire demonstrating increase in productivity possible by vacuum drying.

Read MoreProgram Provides Equipment Maintenance, Overhauls and Upgrades

NPE2024: Program aims to ensure equipment remains at peak performance levels throughout its life cycle.

Read More‘Smart,’ Moisture-Based Drying Technology Enhanced

NPE2024: Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

Read MoreDryer, Blender for 'Real Time' Regrind Usage

NPE2024: Dri-Air Industries and Maguire Products join forces on the former’s second generation of on-demand drying/blending systems for the circular economy.

Read MoreAI Manages Resin Drying Airflows and Throughputs for Energy Savings

NPE2024: Optional feature automates the process of maintaining process-ready resins at perfect temperatures and varied throughputs, while preventing overdrying and realizing significant energy savings.

Read MoreFeatured Posts

Blending Specialists ABS Relaunching Thoreson McCosh Dryer Line

NPE2024: Advanced Blending is taking the wraps off reinvigorated Thoreson McCosh drying line.

Read MoreNovatec Putting the ‘Smart’ In Resin Drying, Conveying

NPE2024: Machine builder gets ‘ludicrous’ by rewriting the rules for material drying and conveying.

Read MoreConnectivity for Material Handling Offers Greater Visibility

NPE2024: Motan solutions integrate data connectivity.

Read MoreCaptive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

WatchBozzelli’s Guide To Specifying a Dryer

Here's a list of 17 things to do when looking for new drying equipment.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreFAQ: Drying

How to dry resins?

Proper drying requires attention to detail in the following areas: temperature and moisture content (dew point) of the inlet air, volumetric flow rate of the air across the pellets, time the material is in the drying hopper, and temperature of the return air coming back from the hopper to the drying unit. There are other areas of concern related to the design and maintenance of the system. This also assumes that a desiccant dryer is being used.

How can I achieve more consistent resin drying?

-

Control Initial Moisture Levels in Undried Resin

-

Size Dryers Properly

-

Dry at Correct Temperature

-

Keep Drying Hoppers Full

-

Limit Machine-Side Material Inventory

-

Keep Airflow Clean and Consistent

-

Invest in a Moisture Analyzer

Drying Supplier Categories

- Chillers

- Water, Oil Manifolds and Couplings

- Water Treatment/Filtration Systems

- Hot-water or Oil-circulating Temperature Controllers

- Heat-transfer Fluids

- Cold-storage Chambers

- Heat Pipes and Related Thermal Conductors

- Used Molds

- Cooling Towers

- Heaters, Heating Elements

- Used Machinery

- Heat-recovery Systems

- Equipment Cleaning Services

- Heat Exchangers

- Ovens