Adapting Recyclate Molding to Customer Requirements

As part of a series of interviews leading-up to K 2022 Show, VDMA interviewed Korbinian Kiesl, president of Billion.

VDMA, Germany’s mechanical engineering industry association, recently interviewed Korbinian Kiesl, president of the French injection molding company Billion, as part of a series of interviews leading up to the K Show in Dusseldorf this October. Kiesl described the rapid progression of recycling adoption since K 2019, and how Billion helps its customers meet appearance expectations while injection molding with recyclate.

Korbinian Kiesl, president of Billion SAS

Photo Credit: Billion SAS

VDMA: Mr. Kiesl, the circular economy requires that plastic recyclates can also be processed. How far advanced is Billion in this field?

Kiesl: The processing of recyclates has switched from being a vision to an everyday topic. These days, we no longer even ask ourselves whether our injection moulding machines can process recycled material. This is now a matter of course. Around 80 percent of our customers already run recyclates on our machines, some more, some less, but 80 percent is an immensely high proportion considering that almost no one was doing this a few years back. Three years ago, these customers were looking at K to see what was technically possible. They asked if we had any experience with these new materials. We were hardly ever asked this question about our experiences. Now, however, we are capable of dealing with concrete projects very quickly.

VDMA: What role does quality play for your customers?

Kiesl: The more homogeneous the recyclate, the better the results for our machines, both in terms of physical properties and appearance, aesthetics. This requires a very good separation of used plastics. The machine can do everything, it's just a matter of whether you want to see the used recyclate or not. In the cosmetics industry - which represents an important customer group of ours - the use of recyclates was hardly conceivable until a few years ago. There, it was always a question of maintaining a flawless appearance. Today, there are customers in this industry who even want a package to show that it contains something recycled.

VDMA: Does the end consumer in cosmetics accept this as well?

Kiesl: Consumers get on board with this issue when they have a certain amount of economic freedom. The more they are under economic pressure, the less responsive they will be to this issue.

VDMA: How important are the costs?

Kiesl: All customers today place their ecological interests and sustainable actions in the foreground. Within the consumer goods sector in particular, there is increasing pressure to do something. But as commercial enterprises, they are naturally looking closely at what is happening in terms of cost, plus there is a lot to be said for recyclates at present. Inflation, as well as the real cost explosion on the raw material side, be it virgin material or even all additives, mean that recycling is becoming more and more worthwhile. Recycling is a reason to invest, especially in difficult economic times.

VDMA: Some users need their products to look good. What can you offer them?

Kiesl: If someone wants to have a smooth surface for aesthetic reasons, then our machine can make a product using the so-called sandwich process. The recycled material is inside the product. On the outside, it is surrounded by virgin material. The recyclate is therefore not visible. The prerequisite is that the chemical properties of the materials used are not mutually exclusive. For example, a furniture manufacturer uses our process to produce flower pots from recycled plastic. Customers from the cosmetics industry are also increasingly requesting this method. In times like these, it is also worthwhile in terms of cost. The product is still flawless on the outside, and cheaper recyclate is processed on the inside.

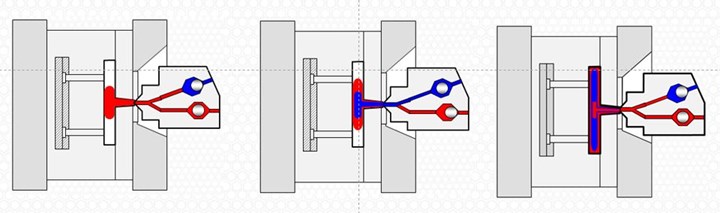

VDMA: How does this process work?

The process works with multi-component technology. There are two injection units that bring the different materials together. We first inject the virgin material into a mould. It clings on the inner walls. Then the second material is injected into the centre of the part, and finally the initial material is used to close the mold, so to speak.

The sandwich molding technique forms a part with virgin resin on the exterior surface and recyclate within.

Photo Credit: Billion SAS

VDMA: In 2019, you had future ideas and visions, in 2022 you have the products and the customers who use them. What’s next on the agenda?

Kiesl: More and more users will utilize recyclates. This trend is irreversible. In addition, it is already becoming apparent today that non-polymeric waste will also be processed. Our customers are already occasionally making products from biomass. They obtain the material from composting plants. These products are then biodegradable at the end of their lives. The use of renewable raw materials and biodegradable raw materials, including biodegradable plastics, will definitely increase in the coming years. Certainly, it will not initially happen in such quality-sensitive areas as medical technology or the automotive industry. But in the consumer goods sector, in white goods or in packaging, for example, the use of renewable or biodegradable raw materials will rise.

Related Content

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MorePurpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More