AI Being Used to Sort Plastics Automatically

The technology from Metaspectral is slated for completion by the end of 2021.

Metaspectral was recently awarded a grant from the CleanBC Plastics Action Fund to support the development of AI-powered technology that can sort plastics automatically. The company offers technology that derives real-time insights from AI using ultra-high-resolution, visible-to-infrared (hyperspectral) imagery.

The company was awarded more than $300,000 in grant funding, which will help develop computer vision, artificial intelligence, and robotics designed to sort consumer waste, which will reportedly improve the quality of post-consumer recycled plastic. The technology is slated for completion by the end of 2021.

“By using ultra-high-resolution hyperspectral imaging, our AI is able to efficiently distinguish among types of plastics for accurate and easy sorting,” said Francis Doumet, CEO of Metaspectral. “It is impossible for humans to differentiate between different types of clear plastic bottles with the naked eye, so until now, various types of recycled clear plastics were sold together in bulk, decreasing the quality and value of the finished recycled material. Our technology will make it possible to differentiate between otherwise indistinguishable materials in real-time, automatically, meaning that large quantities of plastic can be sorted and recycled more efficiently and accurately.”

The company says that this technology will support the circular economy for plastics and stimulate more local processing capacity for recycling as more manufacturers begin using the higher-quality recycled plastics. Both federal and provincial governments have set ambitious recycling targets and have endorsed policy agreements to reduce plastic waste. Metaspectral will also be contributing to the Government of Canada's Greening Government strategy of increasing the ratio of plastics that are recycled to 75% by 2030, up from 9% today.

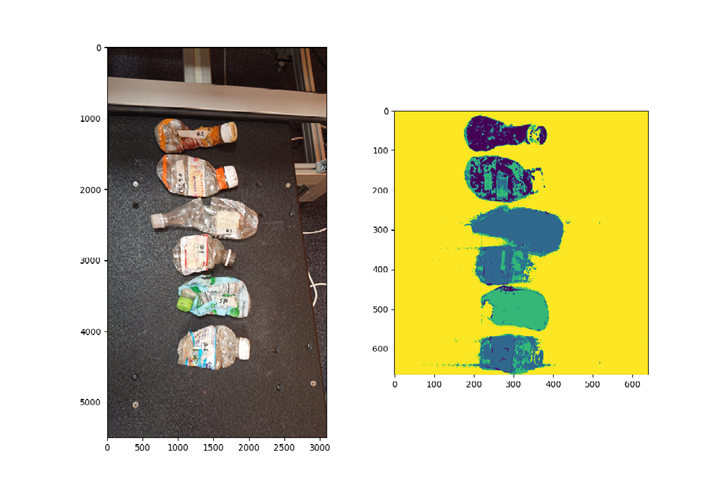

On the left hand side are bottles going into the AI software, and on the right hand side shows the classification from the AI.

Related Content

-

Reversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

-

Building a Future With Sustainable Compounds

With roots in recycling, Star Plastics produces engineering thermoplastic compounds to meet performance and environmental goals.

-

Extrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.