Aptar Food + Beverage Launches PP Seafood Packaging System that Maintains Quality and Freshness

Aptar’s new SeaWell Seafood PP packaging system contains a 100% food-contact-safe absorbents blend.

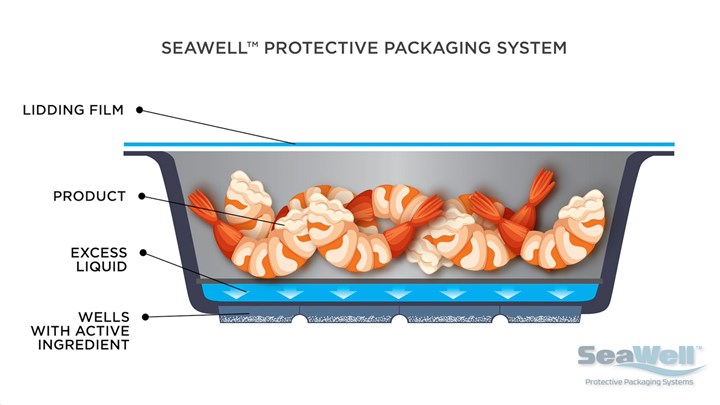

A new thermoformed PP packaging system with a 100% food-contact-safe blend of absorbents that reportedly maintains the quality and freshness of seafood has been developed by Atlanta-based Aptar Food + Beverage, a leader in a broad range of food protection solutions and proprietary active packaging systems for seafood and fresh-cut fruits and vegetables.

Aptar launched its new SeaWell Protective Packaging System with a leading national retailer in more than 3800 store locations. Said to be a first-of-its-kind active packaging solution, the SeaWell active packaging system features integrated technology that absorbs excess liquids that would otherwise accumulate around the seafood, causing potential product breakdown and negatively impacting shelf life. This technology and packaging design separates the seafood from excess liquids, reducing the rate of microbial growth and chemical degradation—the result of a combination of the patented tray design and a layer of nonwoven PP fabric for separation, according to Aptar.

The SeaWell system reportedly improves freshness and visual appeal, absorbs odors, and enhances safety by reducing overall bacteria count and mitigating cross-contamination in the kitchen. In a challenge study on scallops, the SeaWell active packaging system provided a 3 log (99.9%) reduction in aerobic bacteria through day 13. According to the company’s current launch partner, this packaging system has reduced shrink and improved sales in the category compared to the previous packaging solution.

Available in a variety of sizes, the SeaWell system offers sea-to-table protection for both fresh and frozen seafood. The technology also enables seafood processors to pack frozen for distribution and thaw in the same package for fresh sale to market. This provides both consumers and industrial kitchens with an optimal seafood experience and a pristine case-to-cook product. It enables seafood processors to expand their geographic reach as well as help solve the challenges home delivery and grocery markets face as they rapidly expand their customer base and strive to meet increasing demands for delivering the freshest seafood possible.

Related Content

-

Prices of PE, PP, PS, PVC Drop

Generally, a bottoming-out appears to be the projected pricing trajectory.

-

The Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

-

First Quarter Looks Mostly Flat for Resin Prices

Temporary upward blips don't indicate any sustained movement in the near term.