EOS Reports Strong Market Demand for Flexible Lattice Patent

The company says that early adopters of EOS’ digital foam are seeking product differentiation.

EOS is reporting strong market demand for applications featuring its patented 3D printed flexible lattice also known as digital foam.

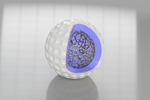

Invented by EOS employees Michael Jan Galba, Monika Gessler, and Johann Oberhofer, the patent relates to any generatively 3D printed object which has a flexible grid-like structure or matrix (i.e., lattice), composed of open cells that are joined together in groups of differing characteristics. This covers any varying 3D printed lattice structures morphing into each other.

“We knew that this process would enable unprecedented manufacturing customization opportunities,” said Michael Jan Galba, one of the patent’s authors. “But seeing the adoption by so many innovative organizations who are really making it a cornerstone of their 3D printed applications has surpassed our expectations.”

“Using our patent, designers are able to make groups of cells creating a lattice that can be engineered with varying levels of compressibility,” Galba said. “One common example we are seeing leverage this IP is in athletic footwear. Now, consumers can purchase footwear tailored to their specific needs or desired performance characteristics, such as shoe soles with varying compressibility in the heel, toe, and arch areas, made all in one additively manufactured piece. This is a great real-world use-case of mass customization.”

Early adopters of EOS’ Digital Foam are seeking product differentiation, competitive advantages, and improved product performance characteristics including safety, comfort, lightweighting and “tuneability.”

Bike seat (saddle) featuring EOS’ patented flexible lattice.

Related Content

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

-

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

-

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.