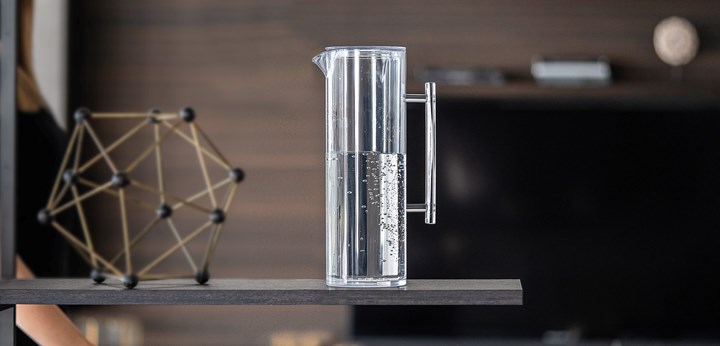

Fratelli Guzzini Selects Sustainable Styrenics from Ineos Styrolution

The styrenics used in the drinkware are based on biomass balanced styrene produced by BASF

Global tableware and household appliance manufacturer Fratelli Guzzini has selected a range of styrenics from Ineos Styrolution’s sustainable NAS Eco materials for its newest range of drinkware solutions. NAS Eco is a SMMA (styrene methyl methacrylate) which is the result of a cooperation between Ineos Styrolution and BASF. It is built on BASF’s production of styrene monomer derived from renewable feedstock based on mass balance processes. Said Fratelli Guzzini’s president Domenico Guzzini, “We are pleased to respond to the growing demand from our customers to deliver solutions with a significantly reduced impact on the environment.”

BASF’s biomass balance (BMB) based styrene is used by Ineos Styrolution in the production of bio-attributed styrenics specialties, mainly transparent styrenics materials such as the company’s NAS Eco family of SMMA and the Luran family of SAN (styrene acrylonitrile copolymer) products. The end-to-end mass balanced based production of the new solution portfolio is certified by ISCC during BASF’s and Ineos Styrolution’s processes. To produce BMB styrene, BASF replaces fossil resources like naphtha or natural gas by renewable feedstocks derived from organic waste or vegetable oils. It is one way to produce styrene via a mass balance approach. Mass balance is a chain of custody model that keeps track of the total amount of (e.g., circular or other alternative) feedstock throughout the production process and ensures a proper allocation to the finished goods.

Related Content

-

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

-

Why Are They Blending Biopolymers?

A sit-down with bioplastic producer Danimer Scientific showed me there are more possible answers to that question than I had previously thought.

-

Avantium and U.S.’s Origin Materials Aim to Accelerate Production of FDCA and PEF

The partnership aims to bring together both companies’ technology platforms to produce FDCA from sustainable wood residues on an industrial scale.