Metal 3D-Printing Technology Targeting Tooling Is Launched

Following successful beta testing of the P-200 printer and TrueShape technology, Mantle has commercially launched its metal 3D printing system, with deliveries planned for the first half of 2023.

Mantle Inc. (San Francisco, Calif.) announced the commercial launch of its metal 3D printing technology for toolmaking. The announcement follows the successful beta testing of the printers at several leading injection molding and moldmaking companies, including Westminster Tool (Plainfield, Conn.).

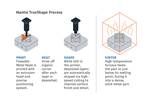

Mantle’s system includes its patented TrueShape technology and P-200 printer. This hybrid system is built on a CNC platform and integrates printing and machining to produce parts with the accuracy and surface finish required for tooling. The P-200 printer has a build volume of 200 by 200 by 150 mm. Also included is the F-200 furnace, which sinters parts from the printer, with one furnace able to sinter multiple parts and support multiple printers.

The package also includes two tool steel materials: H13 and P2X, which the company says is comparable to P20. These materials perform like traditional tool steels supporting secondary operations like machining, polishing, coating and laser welding. Finally, the package also includes software that automates the printing process, including the generation of all toolpaths and machine instructions.

Nicolet Plastics, a full-service custom plastic injection molding company with three facilities in Wisconsin, will be installing one of Mantle’s first production systems. Deliveries of the first systems are planned for the first half of 2023.

Mantle’s technology was used to create this mold cavity running a medical component from acetal.

Photo Credit: Mantle

Related Content

-

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

-

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

-

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.