North American Tooling Industry Increases Utilization, Revenue in 2021

Harbour Results’ benchmarking study found that the tooling industry rebounded in 2021 with companies on average seeing year-over-year revenue growth of 10%.

Mold and die shops saw utilization range between 81 and 89% throughout 2021, and, despite the first quarter starting out slightly slower, forecasts call for utilization to reach 90% in molds and 82% in dies by the fourth quarter of 2022. Those results and more from manufacturing consulting and benchmarking company Harbour Results Inc.’s (HRI; Southfield, Mich.) first quarter IQ Manufacturing Pulse Study. Overall, Harbour’s study indicated that the tooling industry recovered in 2021 from 2020, with companies reporting year-over-year revenue growth of 10%.

Despite the positive outlook, Harbour notes that manufacturing continues to face challenges, including supply chain shortages, raw material availability and high costs, a talent gap and global economic uncertainty. Study respondents said the higher cost of business and access to labor remain the top concerns. Work-on-hold is trending up in the first quarter of 2022, with payment terms and on-time payments of accounts falling after a brief improvement in 2021. As a result, Harbour says Q1 2022 overall sentiment has dropped for the first time since 2020.

Laurie Harbour, HRI president and CEO, still noted a hopeful tone, saying that the company’s automotive tooling launch analysis forecast that the North American automotive tooling spend would amount to $7 billion in 2022, up from $5.4 billion in 2021.

While both die and mold shops saw significant efficiency improvements, the average profitability only improved slightly from 2.9% in 2020 to 3.6% in 2021. HRI posits that this result suggests that the efficiency improvements may be a result of the talent shortage, or the increased cost associated with outsourcing and overtime. The study indicates that shops expect to invest between 4 and 5% of revenue in capital expenditures in 2022.

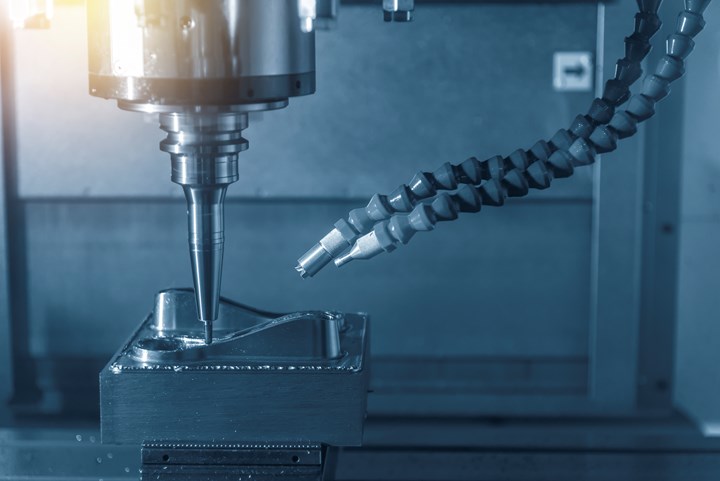

Last year marked a recovery for the North American tool and die industry, according to Harbour Results.

Photo Credit: Getty

Related Content

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

-

How To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.