Novel PET Water Bottle Pushes ‘Eco-Friendly’ Boundaries

Sidel’s AYA offers super-light weight, 100% rPET content, and reduction of secondary and tertiary packaging materials.

An award-winning new PET bottle design from Sidel reduces raw materials usage in the bottle and in paperboard secondary and tertiary packaging, and it uses 100% rPET as well. This past March, the AYA “eco-packaging” concept bottle was awarded the World Food Innovation Award in the category “Best Drink Packaging Design.” This 220-ml bottle for still water has extremely light weight of 5 g. It comes with a snap-on tethered cap and it allows for branding and legally required information to be engraved in relief on the side, thus eliminating the need for a label to reduce cost and waste and facilitate recycling of the PET bottle.

Sidel’s new AYA bottle has a distinctive conical shape and a patented shoulder with three stable positions, a recessed base for head-to-tail nesting, and ability to engrave branding and other information in relief on the side, eliminating the need for labels.

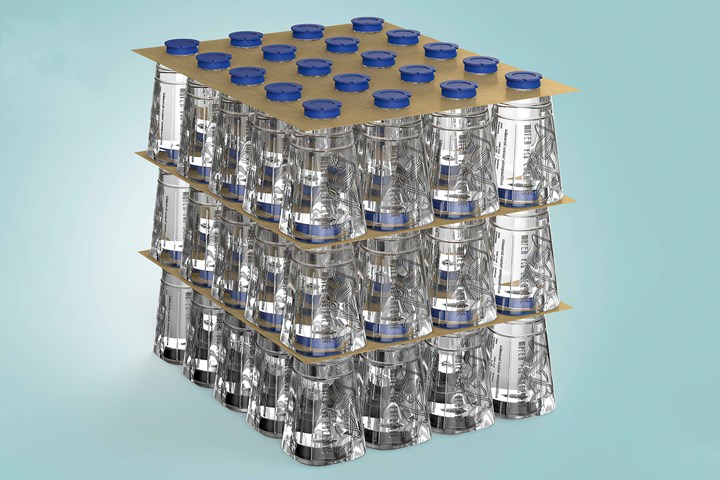

AYA’s conical shape allows for very compact packing in alternating upright and upside-down orientations.

AYA features a distinctive conical or “V” shape that allows for extremely compact packing of bottles in with alternating upright and upside-down orientations. Another option is stacking bottles in the same upright position, which is facilitated by a circular recess in the “BOSS” base, into which the cap of another bottle is nested. Each layer of bottles is held together with a perforated cardboard separator sheet with holes that fit over the bottle necks. A special neck feature also makes such stacking particularly efficient. The patented “Swing” shoulder has three stable positions: After blow molding, the bottle shoulder is deployed in an intermediary position. After filling and capping, mechanical pressure is applied to collapse the shoulder into a lower profile, while also slightly pressurizing the bottle, enhancing its resistance to stresses during shipping and handling throughout the supply chain. When used by the consumer, the shoulder is pulled to a fully extended position that is more ergonomic for opening and drinking from the bottle.

AYA’s conical design helps minimize cardboard secondary and tertiary packaging.

Sidel explains that the name AYA comes from that of an ancient Mesopotamian deity that was considered the master of groundwater, among other things.

Another compact stacking arrangement nests the necks of one bottle layer into the recessed bases of the bottles above. Each layer is held together by a perforated cardboard separator sheet.

Related Content

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

How Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.