First Tech Days Session Launches Tuesday

New technologies in injection molding will be the focus of the first session, featuring four speakers and topics ranging from AI and dual-mold processing to reimagined injection units.

Plastics Technology’s online Tech Days event launches with four speakers addressing new technologies to boost overall efficiency in injection molding operations in different ways, ranging from completely reimagined injection units and the application of artificial intelligence (AI) to a novel shuttle system to double one press’s output with two molds.

On Tuesday, Oct. 1, starting at 1 p.m. Eastern and running to 3 p.m. when a moderated question-and-answer session will be held, the first Tech Days session will focus on new technologies and efficiencies in injection molding in each of the four 30-minute presentations.

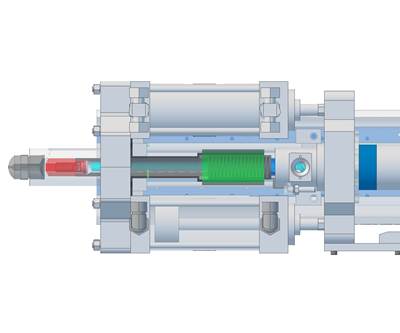

Up first, Mike Durina of Md Plastics will speak on “Rethinking the Injection Unit.” Md Plastics has recently commercialized a new injection unit design that seeks to address the deficiencies of the traditional 70-year-old reciprocating screw. One such issue is inconsistent shot size due to variable closing of the non-return valve. Another is unpredictable plastication due to screw retraction. This specifically causes incoming pellets to experience a constantly changing L/D ratio. Durina will discuss how spring-loaded shutoff valves as well as a screw and inline plunger that reciprocate together can help address these issues.

Following Durina, X2F’s Rick Fitzpatrick will present on “Controlled Viscosity Molding.” In a normal injection molding process, extreme pressure is used to induce shearing and lower the plastic’s viscosity such that the material can flow into a mold. As a non-Newtonian fluid, polymer melt fights against this pressure, forcing the use of large machines and molds while also damaging polymer chains and reducing flow control. Controlled Viscosity Molding manipulates non-Newtonian polymer melt to flow and fill mold cavities, using far less pressure and a higher degree of control, creating the opportunity to “rewrite many of the rules of product design and plastic processing,” according to Fitzpatrick.

Derek Moeller of CognitionWorks will share “Streamlining Overhead Costs with Generative AI: A Processor's Practical How-To Guide.” Moeller will explore how generative AI can transform production efficiency in plastics. This includes the preservation of valuable “tribal knowledge” within a company via artificial neural memory. The talk will also address how to identify hidden production efficiencies via AI-driven analysis, and cutting-edge advancements in cognitive vision and goal-seeking AI agents. As AI evolves, Moeller says AI-powered employees can help reshape the future of manufacturing.

Finally Canon Virginia’s Wayne Daniel will talk about “Dual-Mold Injection Molding: Unlock New Levels of Efficiency.” Canon’s Shuttle Mold System can be integrated with new or existing molding machines to enable two molds to run simultaneously. Not only does this greatly enhance production efficiency but, for longer cycle times, leveraging the cooling time of the initial molding cycle to produce parts on a second mold maximizes the use of time and resources. Daniel notes that the seamless combination of a second molding process within the first cycle also reduces energy consumption, leading to not only higher productivity but significant cost savings.

More Tech Days to Come

Every Tuesday in October, Plastics Technology will host a series of online presentations given by industry suppliers and subject matter experts. The topics to be covered include:

- Injection Molding — New Technologies, Efficiencies

- Film Extrusion — New Technologies, Efficiencies

- Upstream/Downstream Operations

- Injection Molding — Sustainability

- Extrusion — Compounding

Related Content

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreInjection Molding: Novel Injection Unit With In-Line Screw/Plunger

Md Plastics has a new injection unit designed to overcome longstanding limitations of reciprocating screws.

Read MoreControlled Viscosity Molding Machine Adds Rotary Table

X2F says the addition of a rotary table to its machine reduces cycle times and opens up higher-volume production possibilities—up to four million parts per year.

Read More