Protolabs Launches Revamped Digital Quoting Platform

Initially unveiled in Europe, the new digital manufacturing platform will be coming to the U.S. in early 2021, bringing greater speed and flexibility to quoting of injection molded, CNC machined, and 3D-printed parts.

After years of development informed by direct customer feedback and large-scale beta testing, Protolabs has introduced an overhauled digital manufacturing platform that it says streamlines quoting and ordering, while accelerating product development and on-demand manufacturing.

Mark Flannery, Protolabs global product director of e-commerce, told Plastics Technology the platform relaunch had a primary focus. “We’ve really rebuilt our entire manufacturing system around speed,” Flannery said. “Not just the speed of getting a quote, but really the speed of the whole product lifecycle, from transforming ideas into products.”

The company was founded in 1999 by Larry Lukis whose frustration with the lead time on injection molded parts lead to the creation of a new business. More than a million lines of code later, the quoting platform at the heart of the company was created, and now, just over 20 years since then, it has been revamped.

“We’ve built on that original platform with millions more lines of code for the digital manufacturing system,” Flannery says. “Really helping customers get to market faster was a driving impetus or catalyst of our new platform.”

Quoting and DFM

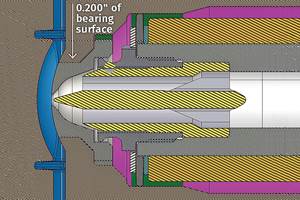

The new platform still functions the same, with users uploading a CAD file to start the digital quoting process. Flannery notes that this goes beyond spitting out a price for the desired part. “Not only are you getting pricing and lead time,” Flannery says, “but most important and the core of our system—both in the old system and the new system—is our design for manufacturability.”

Using this technology, Protolabs digitally manufactures the component and provides feedback on the feasibility of its design. This feedback include recommendations on alterations that could improve the form, fit and function of the part, as well as reduce its total cost and lead time. Flannery said with the new platform, Protolabs has made that experience very similar for users, whether they’re quoting parts that are molded, machined, or 3D printed. Another element that has been added to injection molding quotes, is a total cost of ownership price graph. This allows customers to calculate how elements like number of cavities can impact piece-part price.

Protolabs online quoting platform allows users to calculate how elements like the total number of cavities can impact piece-part price.

Streamlining for Speed

Much of the improved speed has come from targeting “lag points”, according to Flannery. For example on a molded part, a user could approve the location of a gate and an ejector pin prior to checkout, instead of having to reconnect once the order is placed. “We have an end-to-end digital thread,” Flannery says, “which is the key part of what makes our system so powerful.” From an organization and collaborative standpoint, the platform allows users to categorize quotes and projects, while the team function lets engineers work on the same part and the same quote with shared real-time editing.

Initial Feedback

Still early days but Flannery said initial feedback from European customers stressed the swiftness of the revamped program. “Not only the speed of something like uploading,” Flannery said, “but you can configure multiple parts at a time, where in the past you could only do one.” Beyond faster networks and computers, gains have also been made through targeted queries. “We’ve streamlined the system end to end, and we ask some better questions to get more clarity up front,” Flannery says, noting this can reduce the amount of back and forth between the customer and Protolabs.

Flannery says Protolabs has also improved the ability to calculate manufacturing lead times and shipping. “It’s much more like Amazon—how fast would you like it,” Flannery says. “You can say, ‘I’d like to receive it by this date, and you just pick that and we’ll schedule it based off the selection.”

Related Content

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreHow to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreRead Next

Protolabs Will Now Offer the Carbon Platform to Its 3D Printing Services

Greg Thompson, Protolabs' global product manager for 3D printing, discusses why the Carbon technology is a good fit for Protolabs’ customers.

Read MoreUpdated: Protolabs Pandemic Response—7.6 Million Parts and Counting

At first a stop-gap for interrupted Chinese production then a bulwark of emergency medical production at home, Protolabs’ response to coronavirus continues, nearly 8 million parts and counting.

Read MoreProtolabs CEO Discusses the Digital Age of Manufacturing

As the company reaches its 20-year milestone, Plastics Technology talked with Protolabs CEO Vicki Holt about what’s next for the innovative company.

Read More