Rosti North America Opens Digital Innovation Lab

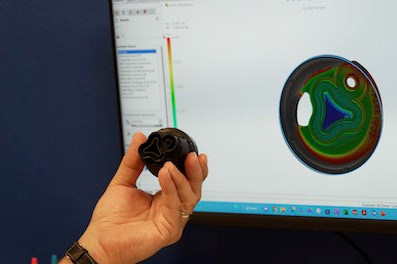

Rosti says its new lab will support injection molding and advance rapid prototyping.

Rosti North America, a division of global injection molder and contract manufacturer Rosti Group, opened a Digital Innovation Lab within the company’s Germantown, Wisconsin, manufacturing facility.

Created via an investment of $1.3 million, the latest facility joins sister labs in Asia and Europe. With this lab, Rosti says it can support 72-hour turnarounds for new concepts. Upon receipt of customers’ 3D product data and specifications, digital simulations are developed to model potential gating, cooling, distortion and cycle times.

These simulations inform the tooling process, and printed tool cavities and cores are developed using high-temperature resins. The moldings undergo optical laser scanning, providing full metrology reports within minutes, and they ready for physical testing within 72 hours. Headquartered in Malmö, Sweden, Rosti has 3,200 employees across 11 facilities in the U.S., Europe and Asia.

Rosti says its new innovation lab in Wisconsin will help it expedite the design and creation of new parts. Photo Credit: Rosti

Related Content

-

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

-

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

-

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.