TC Transcontinental Installs 'First Ever' BOPE Line in North America

TC Transcontinental Packaging will be installing what it says is the first-ever biaxially oriented PE (BOPE) line in North America.

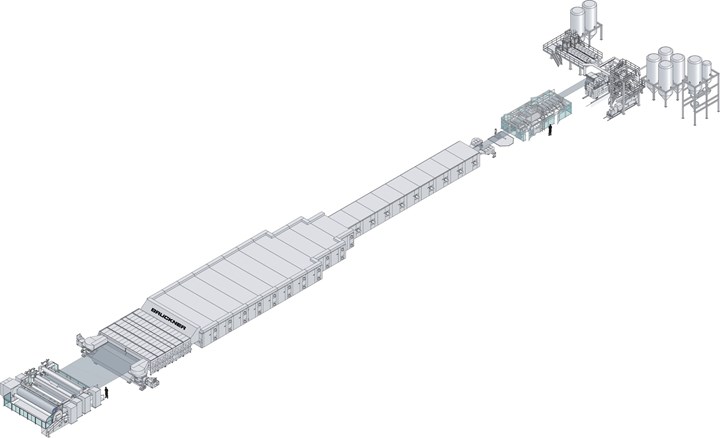

TC Transcontinental Packaging will be installing what it says is the first-ever biaxially oriented PE (BOPE) line in North America. Scheduled to be commissioned in the spring of 2024 at the company’s Spartanburg, S.C. plant, the new line is part of a $60 million investment that expanded the plant by 120,000 ft2.

Supplied by Breuckner, the line will enable the company to expand its offering of sustainable packaging solutions. TC Transcontinental Packaging is a leader in sustainable product development through investments in its R&D team and technologies, and the dedication of its people. The flexible packaging firm’s vieVERTe product line includes structures that are recyclable, compostable, and made from PCR content.

Rendering of BOPE line to be operational next year at TC Transcontinental. Image: Breuckner/TC Transcontinental

Says Thomas Morin, president and CEO of TC Transcontinental, “This new offering will be a game changer in TC Transcontinental's recyclability journey, demonstrating our commitment to distinguish ourselves and gain market share with innovative sustainable solutions for our customers. Our offering aligns with our customers’ desire to accelerate speed to market with recyclable products that also protect and preserve customers’ content throughout the life cycle of their products in addition to creating a more circular economy for plastic.”

Adds Alex Hayden, TC Transcontinental’s senior vice president, R&D, Innovation, Sustainability, “Our investment in BOPE is a strategic decision that positions us to address sustainability shortcomings in existing offerings. This new equipment will advance the commercialization of recyclable film solutions to meet the challenging requirements of our different applications without sacrificing fill speed or performance.”

Related Content

-

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

-

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.