SAN and SMA Copolymers Based on Renewable Feedstocks

Ineos Styrolution’s NAS Eco and Luran Eco product ranges have a carbon footprint reduction of 77% and 99% compared to fossil-based styrenics.

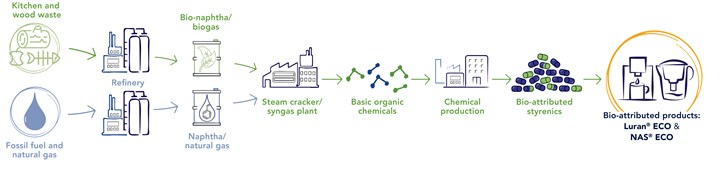

Two new biobased styrenic resin series intended as a drop-in for their fossil-based counterparts have been launched by Ineos Styrolution. Luran Eco and NAS Eco are transparent styrenics specialty materials based on a mass balance process certified by ISCC Plus. The products are based on styrene being produced using renewable feedstock that is not in competition with food production, such as kitchen waste and wood waste. The carbon footprint reduction for the new products varies between 77% and 99% when compared to the respective fossil-based products, depending on the amount of renewable feedstock used to produce a material.

Luran Eco is a SAN (a styrene acrylonitrile copolymer) boasts a well-balanced property profile ranging from good transparency and excellent chemical resistance to high stiffness, extraordinary heat resistance as well as very good dimensional stability. These attributes make these resins a material of choice for a variety of household and cosmetics packaging applications. NAS Eco is a stiff, amorphous SMMA (styrene methyl methacrylate) copolymer for demanding applications requiring excellent transparency such as water tanks, displays, food containers or boxes. NAS is said to feature an outstanding water-clear appearance, an extreme low haze as well as a good thermal and chemical resistance. The optical properties of NAS Eco are on a similar level as PMMA, while NAS has a density and processing advantage compared to acrylic solutions.

The new materials reportedly have identical physical and mechanical properties as their fossil-based counterparts Luran and NAS, enabling a direct replacement for customers seeking to step up their sustainability efforts. Said v.p. specialties Eike Jahnke, “These new solutions expand our portfolio of mass balance-based specialty styrenics products. Together with the previously introduced Styrolux Eco and Styroflex Eco families (biobased SBC copolymers), Ineos Styrolution can now offer its customers sustainable drop-in solutions for four of its specialty product families.”

Related Content

-

Prices of Volume Resins Generally Flat or Lower

Exceptions in early March were PP and PS, which moved up solely due to feedstock constraints, along with slight upward movement in PVC and PET.

-

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

-

Tracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.